1x1 is a German-based design company founded by lifelong friends Max and Yannik. With Max's experience from top design studios and Yannik's expertise in 3D printing and algorithm programming, they created 1x1 to change how we create and use everyday products. Their mission focuses on making custom furniture, lighting, tools, and accessories using locally sourced and repurposed materials, promoting a circular production model with a low carbon footprint.

In this interview, Max and Yannik share their journey, including the market needs that inspired 1x1 and the challenges they overcame to develop their unique production system. They discuss the role of Grasshopper and ShapeDiver in bringing their designs online and the importance of an easy-to-use online configurator. They also highlight how their products support sustainable living through modular design and community collaboration.

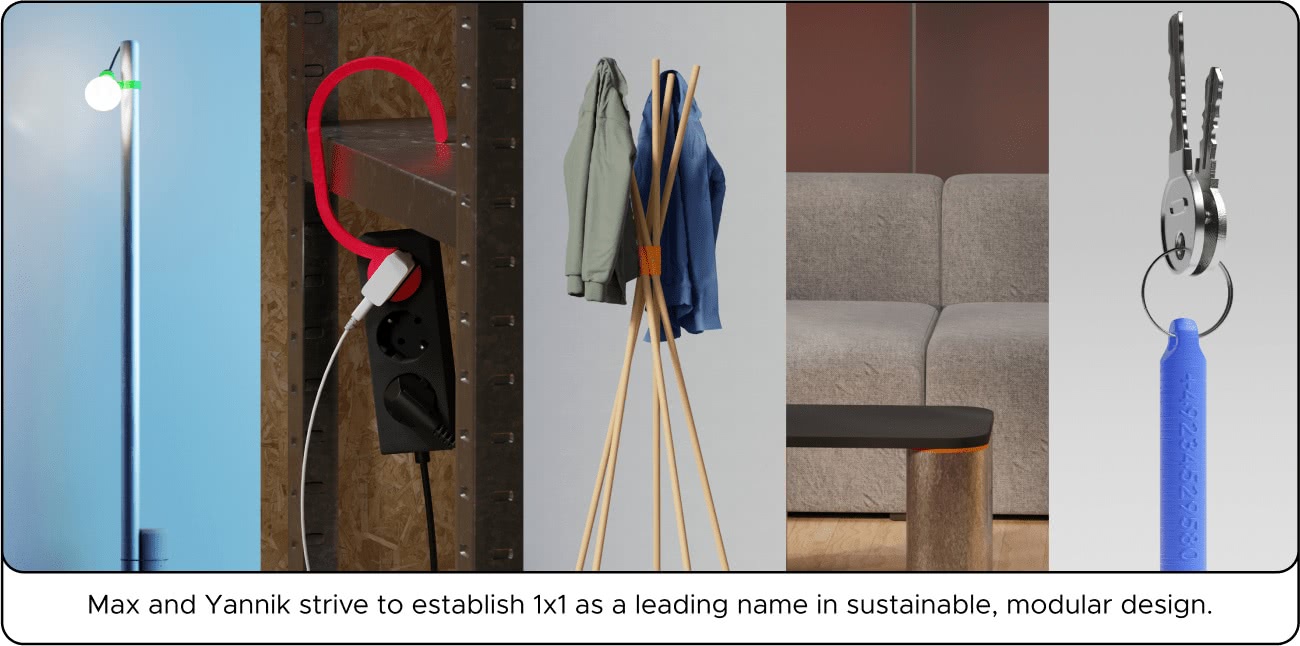

Join us as we learn about 1x1's mission, their work with other designers, and their plans for future growth. This case study offers an interesting look at how 1x1 makes sustainable, modular design accessible to everyone, paving the way for a more eco-friendly lifestyle. Let’s dive in!

1. How did your team at 1x1 come together, and what backgrounds do you bring to the company?

We grew up in the same village and have been friends for over twenty years. Max studied design in Cologne and worked at Meire und Meire, Meta Design, and Random Studio. Yannik is a trained carpenter and product designer with deep expertise in 3D printing and algorithm programming. We both love design systems and are passionate about solving current problems in design and production. 1x1 has been in the making for the past five years.

2. What specific needs did you identify in the market that drove you to create 1x1 and its products?

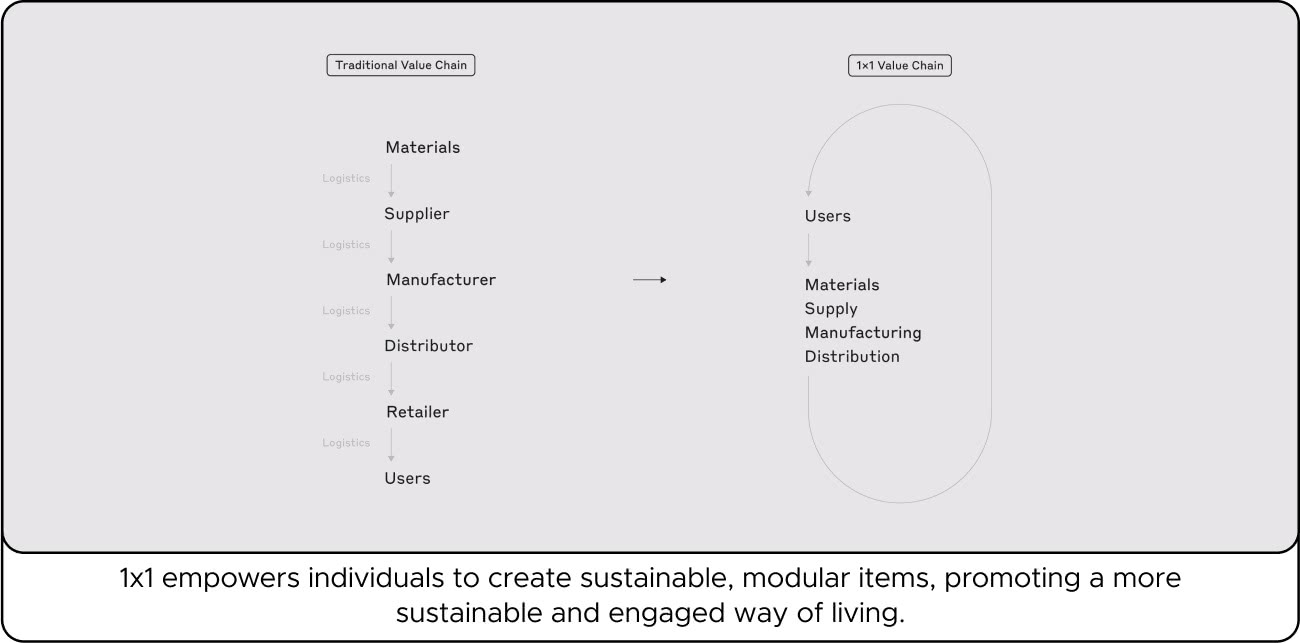

We created 1x1 to address several critical needs: reducing the high CO2 emissions from global supply chains, improving the repairability of products to combat the throwaway culture, and enhancing the resilience of production systems against disruptions.

We also aim to reconnect consumers with the manufacturing process by offering high-quality, customizable products that can be locally produced. By overcoming the low design standards and technical complexities of existing 3D-printing solutions, 1x1 empowers individuals to create sustainable, modular items, promoting a more sustainable and engaged way of living.

3. What key challenges did you encounter while developing your circular production system and modular design philosophy?

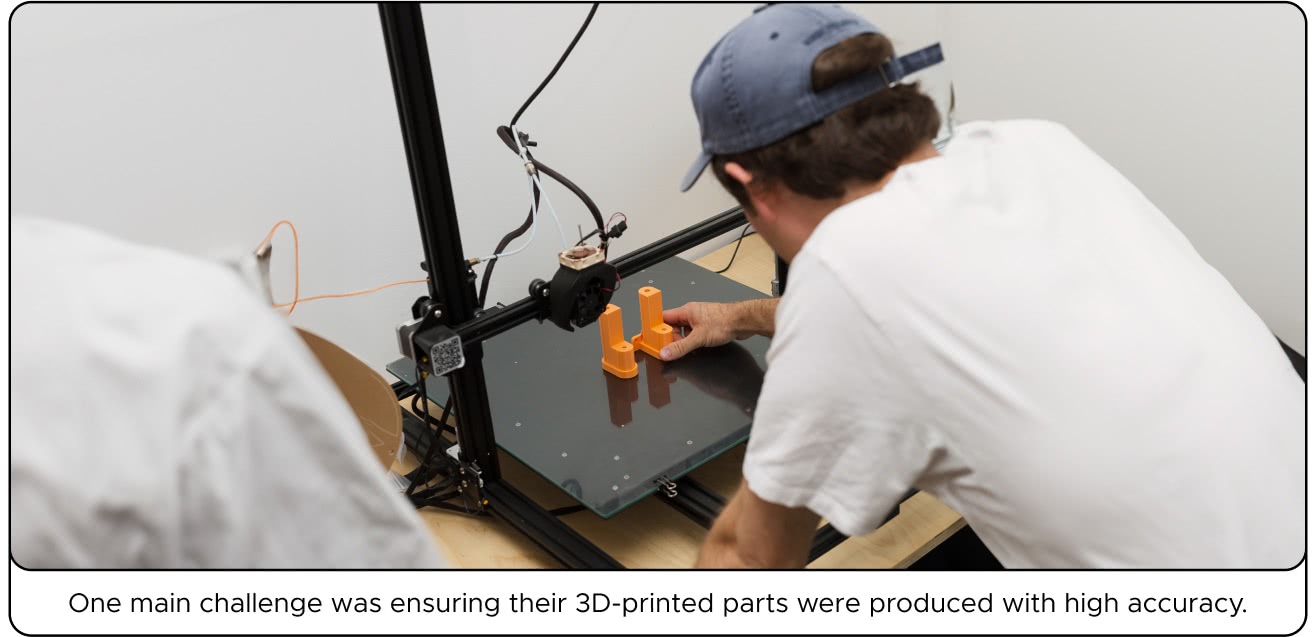

A major challenge was creating modular, highly customizable products while maintaining a clear identity and consistent design language. Another hurdle was ensuring our 3D-printed parts were produced with high accuracy and managing tolerances for both printed and non-printed parts. Additionally, realizing complex and physically demanding components, like ball joints, using 3D printing technology presented its own difficulties.

4. Why did you choose Grasshopper as a platform for your parametric designs, and how does it help you achieve your goals?

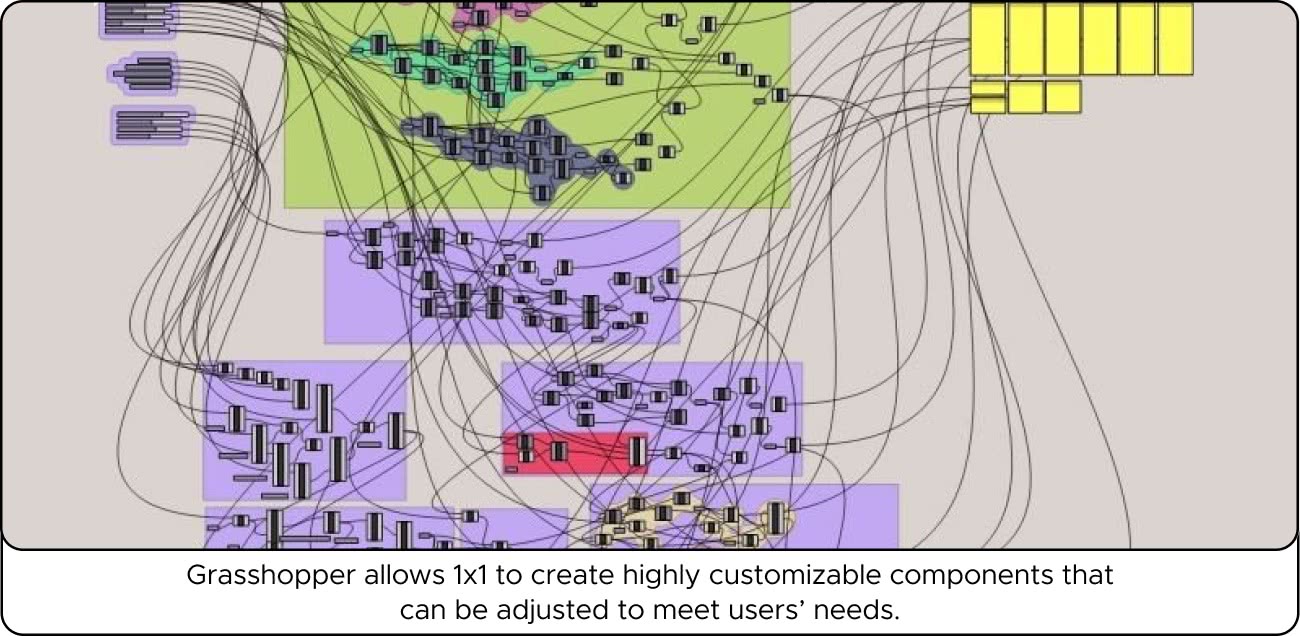

We chose Grasshopper for its powerful integration with Rhino, which we and other designers have used to create static products. It was natural to use a familiar tool that connects seamlessly. Grasshopper allows us to create highly customizable components that can be easily adjusted to meet user needs. Its algorithm-driven components ensure adaptable and precise designs, aligning with our modular and circular production principles.

5. How does ShapeDiver help you create your online configurations and bring your parametric designs to life?

ShapeDiver is essential for bringing our parametric designs online. It allows users to interact with and customize products in real time, enhancing the user experience and ensuring each product meets individual needs. Its real-time rendering and AR functionality make our complex designs accessible and user-friendly, helping users visualize their creations before purchasing print files and manuals.

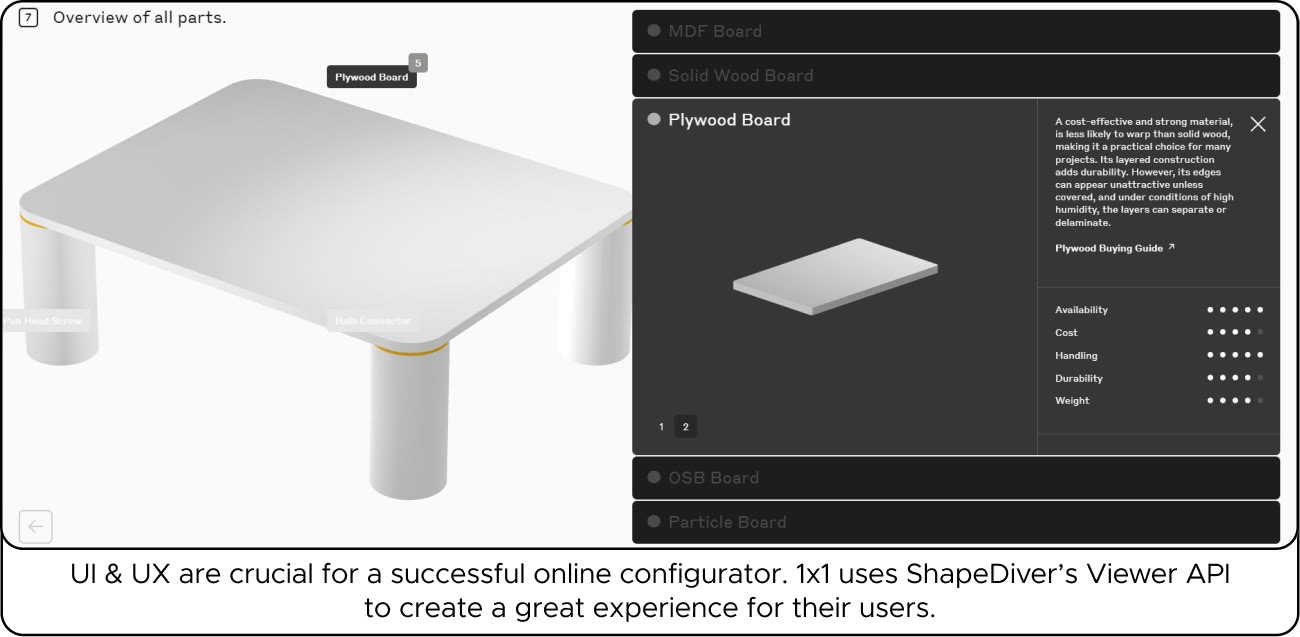

6. How important is UI and UX in building a successful online configurator for your users?

UI and UX are crucial for a successful online configurator, ensuring easy navigation and visualization of products. We focus on making our configurator accessible, user-friendly, and visually appealing to drive adoption and promote our sustainable offerings, empowering users to create custom products confidently.

7. Can you elaborate on how your products embrace the principles of circular production and how this benefits your customers?

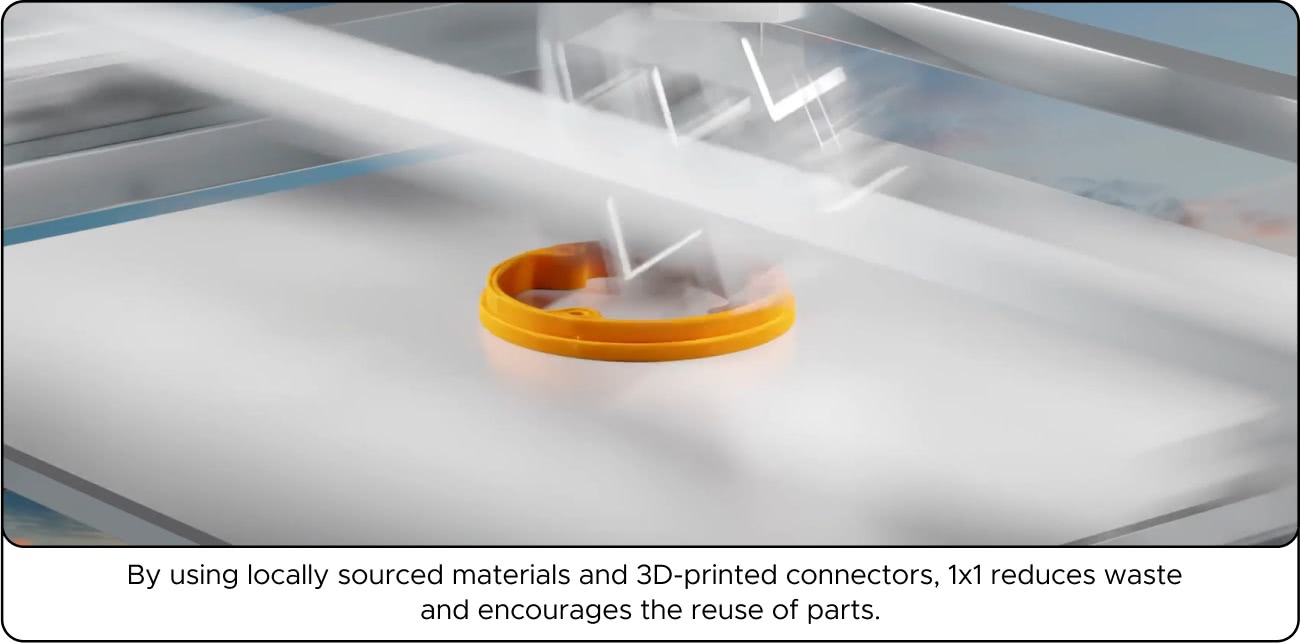

Our products are designed with circular production principles at their core, meaning every component can be easily disassembled, repaired, or recycled. By using locally sourced materials and 3D-printed connectors, we reduce waste and encourage the reuse of parts. This modular approach extends the lifecycle of our products and empowers customers to engage in sustainable practices, reducing their environmental impact and fostering a sense of ownership and responsibility.

8. How does fostering a community-driven approach at 1x1 contribute to better products and sustainable living?

Fostering a community-driven approach is central to our mission. By enabling users to connect, share resources, and collaborate on projects, we create a support network that enhances the overall experience and encourages sustainable practices. This community aspect helps users achieve their goals more effectively and builds a collective commitment to sustainability.

9. Could you share your vision for unifying the configurator, marketplace, and production facilitation into a cohesive online platform?

Our vision involves integrating the configurator, marketplace, and production facilitation into a seamless user experience. Users will be able to customize products through the configurator, source materials and components via the marketplace, and receive guidance on local production options. Currently, we split these aspects between our website and Discord channel, but we aim to unify them.

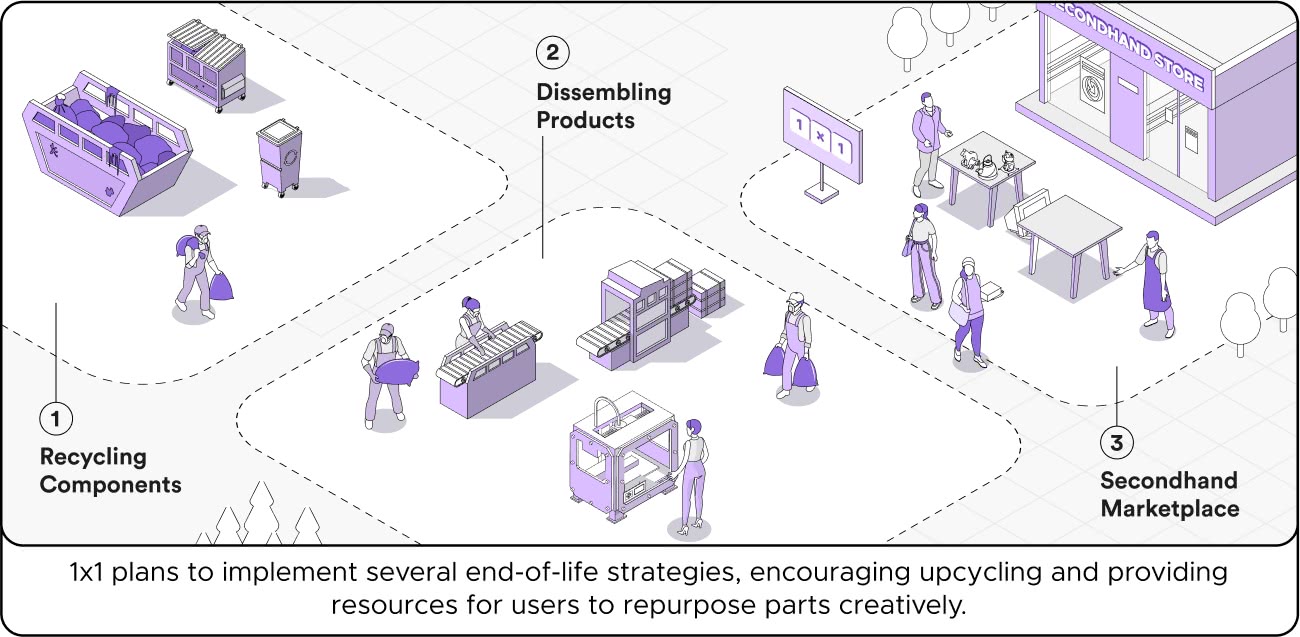

10. What viable end-of-life strategies do you plan to include to ensure a truly circular product lifecycle?

We plan to implement several end-of-life strategies, including take-back programs for recycling or repurposing components, detailed disassembly instructions, and a marketplace for second-hand parts. By facilitating these options, we aim to minimize waste and ensure that materials are continuously cycled back into use. Additionally, we encourage upcycling and provide resources for users to repurpose parts creatively.

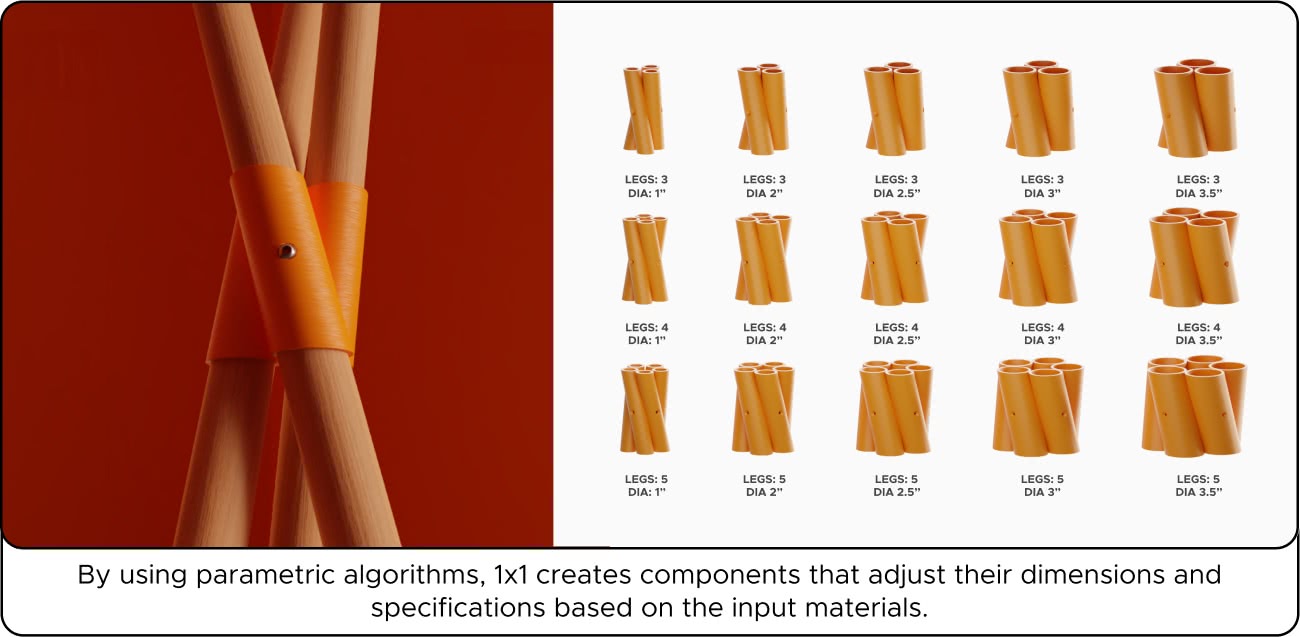

11. How do your parametric designs ensure custom parts are compatible with various locally sourced materials?

Our parametric designs are highly adaptable, allowing precise adjustments to fit a wide range of locally sourced materials. By using parametric algorithms, we create components that adjust their dimensions and specifications based on the input materials. We continuously improve our parts, like software, based on testing and user feedback.

12. How do collaborations with designers like Christoph Hauf and Studio Πenhance the diversity and creativity of your product lineup?

We see ourselves as a label for DIY products with a very high design standard, and working with the best in the field was logically the only way to create an offering that can compete with the Vitras and Ikeas of this world.

13. What are your goals for future growth in expanding your online presence and product range?

Our goals include expanding our online presence to reach a broader audience and diversifying our product range. We plan to enhance our digital marketing efforts, leverage social media, and form strategic partnerships. We also aim to introduce new product categories and collaborate with more designers to keep our offerings fresh and innovative. Ultimately, we strive to establish 1x1 as a leading name in sustainable, modular design, significantly impacting how people create and consume products in an environmentally conscious manner.

- Thank you very much for both of your time!

Thank you for sharing this space with us as well!

That's it for this new edition of Getting to know... Don't forget to visit

1x1's website

and I

nstagram page!

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1201x631/d111cb5988/cover.webp)