Beaver is an open-source plugin for Rhino3D and Grasshopper meticulously crafted to adhere to Eurocode 5 standards. It ensures that timber structures are not only innovative but also safe and compliant. Beaver is developed with both educational value and real-world application in mind, and it integrates with Karamba3D to provide a seamless and intuitive analysis environment for structural engineers and designers.

In this case study, we sat down with João, Marcio, and Renan, the minds behind Beaver, to explore the journey from academic research to a tool now used by industry leaders across the globe. We discussed the inspiration behind focusing on timber engineering, the specific market needs that Beaver addresses, and the significant role that Eurocode 5 plays in shaping the tool’s core functionalities. Our conversation also dives into the challenges faced by professionals in the field and how Beaver’s open-source nature fosters collaboration and innovation. We also explore how companies like ITA Engenharia em Madeira are using Beaver, alongside ShapeDiver, to push the boundaries of what’s possible in timber construction.

Through this case study, you'll gain insights into how Beaver allows engineers to transition from being safety-checking specialists to becoming integral parts of the design process and how integration with tools like Karamba3D and ShapeDiver simplifies complex tasks into manageable workflows. Let’s dive in!

1. Could you share a bit about your background and how your experiences led you to develop Beaver for timber engineering?

We come from a research background in membrane structures, where the geometry design depends on the applied force on the structural system. Hence, multiple geometries must be considered before arriving at a final design; this is called the form-finding process. We saw that we could apply this same concept to more conventional engineering problems if we could verify multiple solutions.

In that context, Beaver started in 2018 as a bachelor's thesis at the University of São Paulo, Brazil, and has been developing since then.

2. What inspired you to focus specifically on timber engineering within computational design workflows?

Timber engineering was experiencing rapid growth in terms of novel structures at the time because of its advantages as a sustainable material. However, there was (and still is) a gap between engineering knowledge and tools that allow bolder designs to be realized.

3. What specific gaps or unmet needs did you identify in the market that led to the development of Beaver?

The typical work at engineering firms consists of building a geometry model, exporting that geometry to FE software, analyzing it, making design proposals, and then restarting the loop.

We wanted to bring the design and engineering disciplines closer together by having an integrated workflow. A few tools already existed then, but none specifically for timber engineering.

4. How did Eurocode 5 shape the core functionality of Beaver, and why was it a crucial reference?

It was the basic requirement for guaranteeing building approval for whatever you’re designing. Many design codes use the same analysis methods, and even different methods are commonly benchmarked against the Eurocode.

5. What are some of the primary challenges Beaver solves for professionals in the timber engineering field?

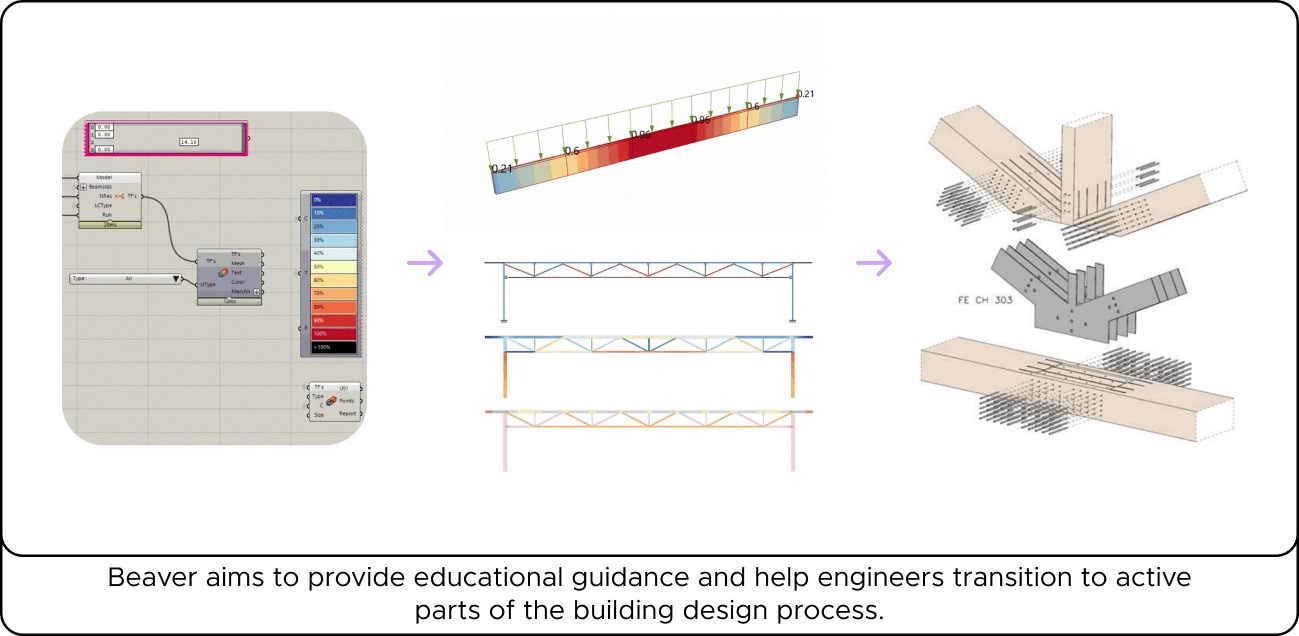

Our project aims to have two major impacts: (a) Beaver offers educational guidance. The live-fed analysis builds up to the engineer's intuition much faster than normal workflows, and (b) it allows engineers to transition more easily from safety-checking specialists to active parts of the building design process.

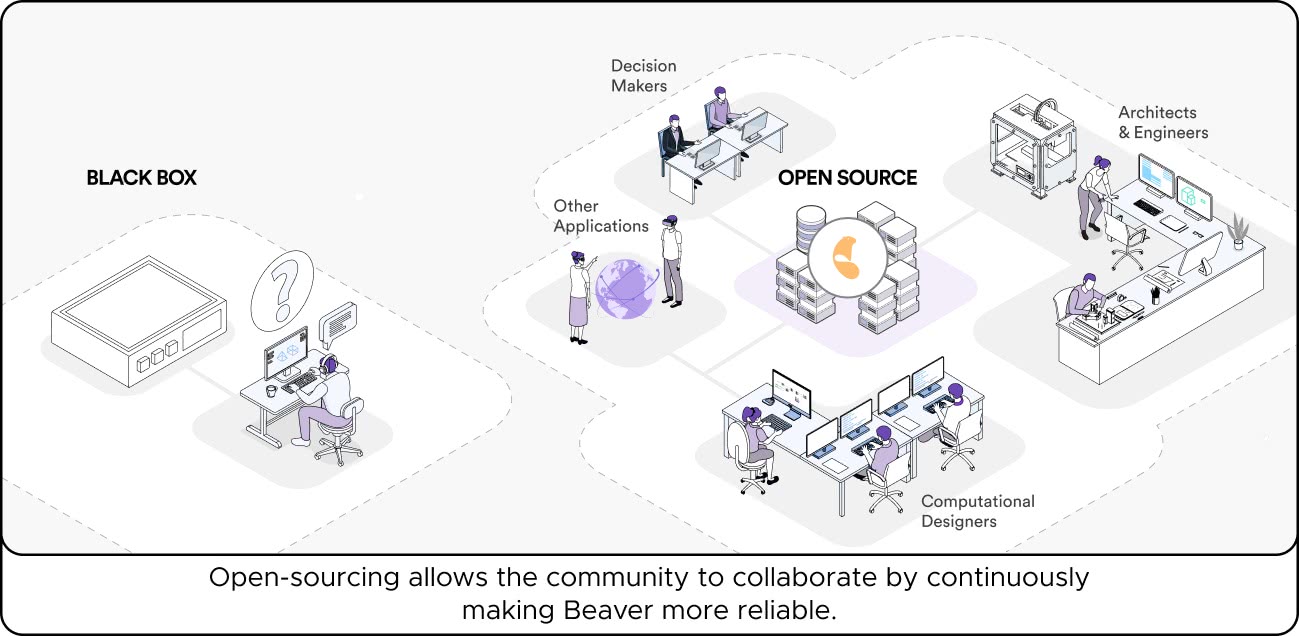

6. In what ways does Beaver’s open-source architecture enable collaboration and innovation for research and professional purposes?

We’ve identified that most engineering professionals avoid exploring other tools when they encounter the "black box” feeling, that is, when they’re unable to discern what happened inside the algorithm. Open-sourcing tackles that and allows the community to collaborate by continuously making our tool more reliable.

Regarding research, we had several requests for students to write theses at different levels of the academy, but we’re not yet able to tell what their future products will be.

We are always looking for people to collaborate with us, as our roadmap still has many features to develop.

7. How does Beaver help designers overcome data exchange and workflow integration difficulties between CAD/CAE models?

Having an integrated workflow between geometry, analysis, and post-processing allows many other disciplines to participate in the design process, such as evolutionary solvers, multi-objective optimizations, machine learning, and other form-finding processes.

8. Why is ShapeDiver's support for Beaver important, and what unique advantages does it bring to your users?

With a fast-growing market for timber structures worldwide, pushed by a need for renewable and low-carbon construction methods, Beaver is presented as an alternative for fast and straightforward analysis of timber structures. Along with ShapeDiver and Karamba3D, this combination may be a great tool that can be presented to clients very straightforwardly without needing to access complex grasshopper definitions on the go.

ITA Engenharia em Madeira, for example, has recently developed a tropical hardwood concept design tool with ShapeDiver for the South American context. It will soon be available for architects and engineers on a web platform with a very simple user interface. This would not be possible without ShapeDiver.

9. Could you explain how Beaver's integration with Karamba3D improves users' workflow?

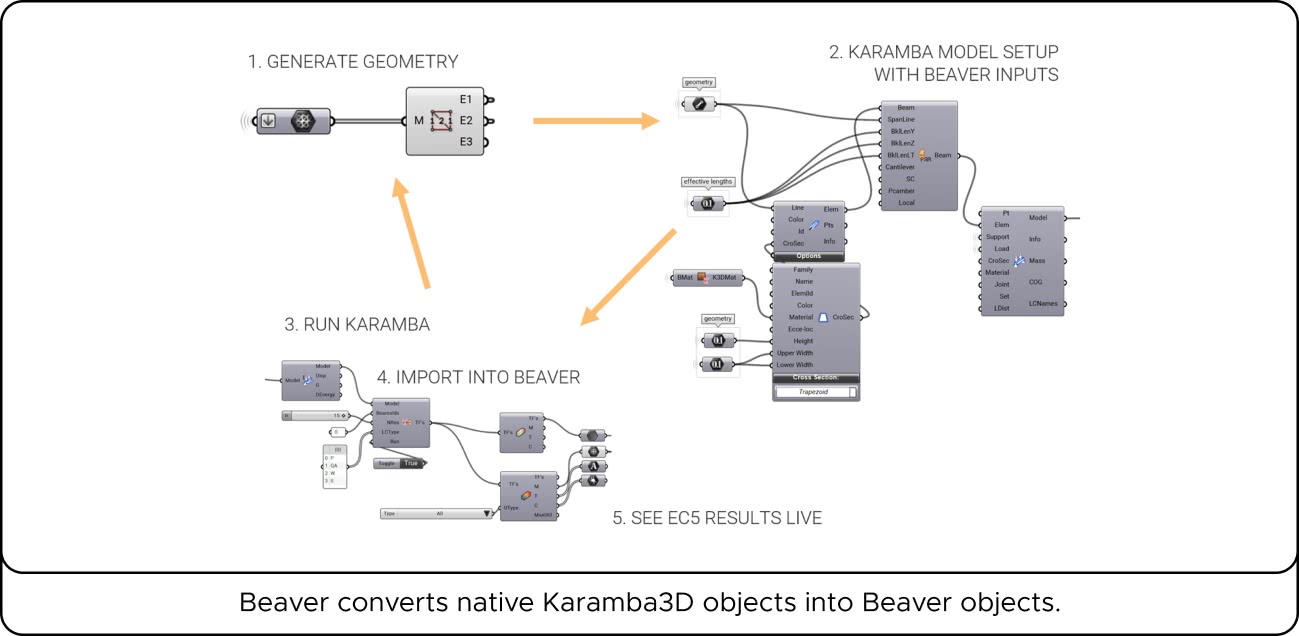

The integration converts native Karamba3D objects into Beaver objects. So, to get the analysis up and running, any user with some experience on Karamba3D just needs to add about four more Beaver components.

10. What types of projects are ideally suited for Beaver, and why do your clients prefer it over other tools?

Typically, these are projects that demand computational design workflows or when some sort of geometry optimization is needed. Otherwise, modularity is also an important aspect since a reliable model can be built with very little time and effort.

11. Could you share some examples of clients currently using Beaver and how they benefit from the plugin in their projects?

Beaver is currently used by known timber engineering companies in North and South America, Europe, and Asia, especially for parametric concept designs. We are reaching a milestone of 1000 licenses distributed, some of which belong to companies we consider world leaders.

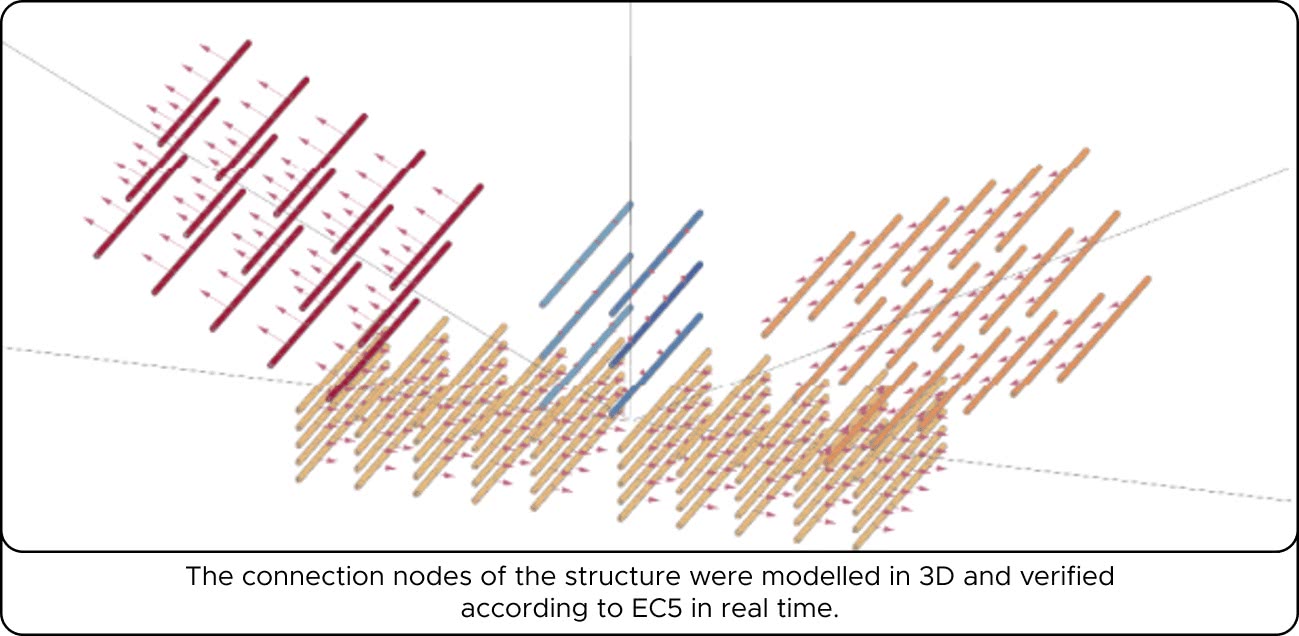

ITA Engenharia em Madeira has recently developed an active-bending timber beam string that spans over 20 meters for boat hangar structures. This structure was developed using Karamba3D, Beaver, and genetic algorithms available in Grasshopper. It has achieved a remarkably low timber consumption and was selected to be presented at the IASS2024 (International Association of Spatial Structures) in ETH Zurich.

12. What are the most important components of Beaver, and how do they contribute to the overall effectiveness of the plugin?

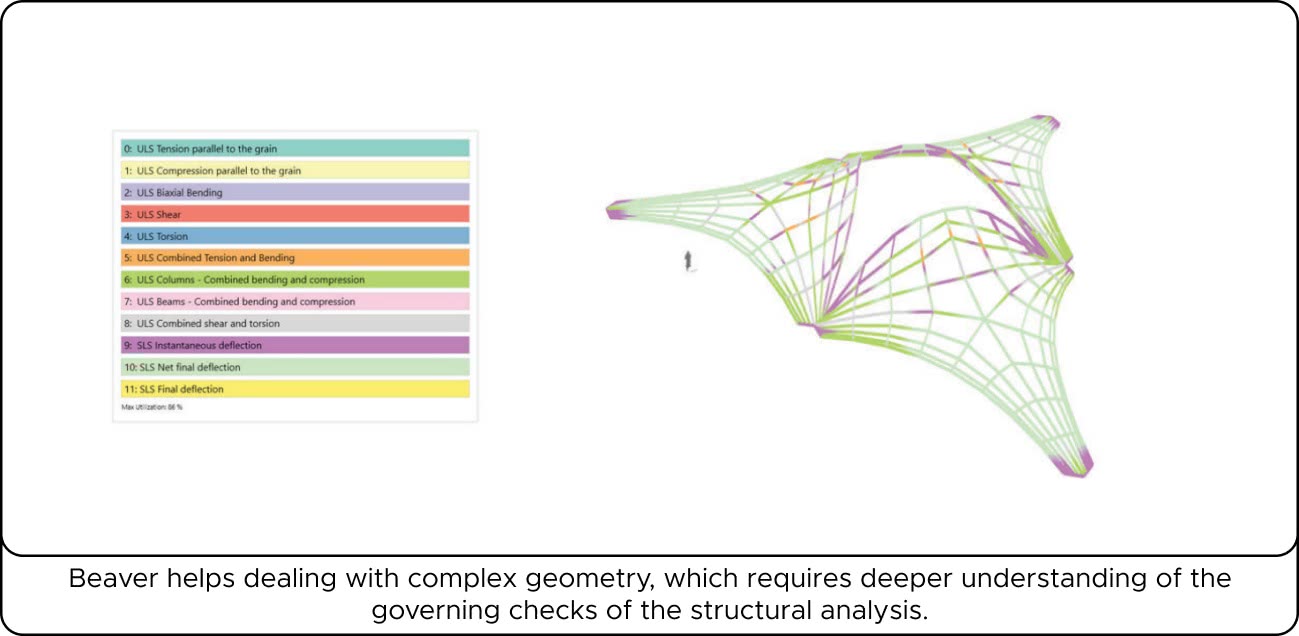

The easiest way to use Beaver is to benefit from its seamless integration with Karamba3D. Hence, by simply connecting the Karamba3D model to the “Karamba to Beaver” component, all finite element analysis data from Karamba will be automatically analyzed by Beaver according to Eurocode 5 standards. Also, the visualization components allow users to easily understand the Beaver evaluations along the structure in the Rhino 3D model.

13. How do the calculation reports generated by Beaver provide users with a transparent and educational overview of their timber design decisions?

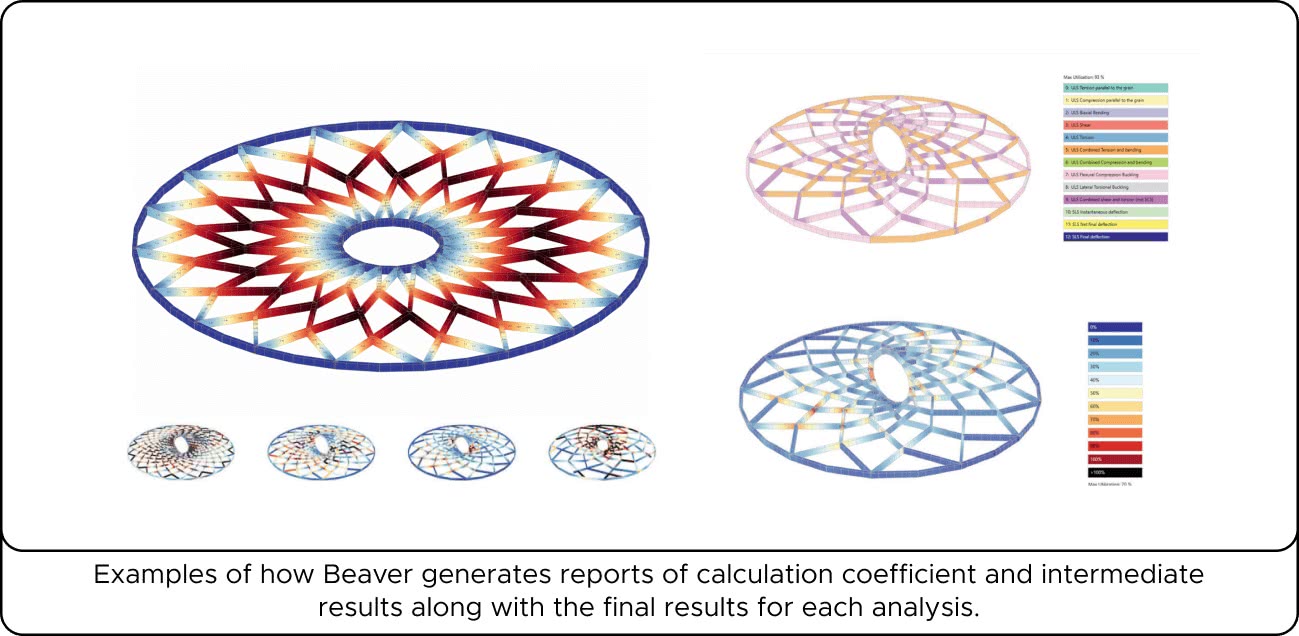

The Beaver report showcases each calculation coefficient and intermediate results, along with the final results for each analysis. This allows the user to understand if any configurations must be redefined and follow the eurocode procedures done by Beaver in a transparent and reliable way.

14. What makes Beaver's calculation reports particularly valuable in benchmarking and educational contexts?

Beaver is an open-source project that is growing with the help of the community. The calculation reports have been very important for users to report bugs and also allow them to compare Beaver to more traditional software to check its reliability.

Beaver was primarily created for concept design since the parametric environment is great for that. Once the geometry is defined, a double check is always recommended with traditional non-parametric FEA software. Thankfully, due to the community that has helped us find inaccuracies, Beaver is now showing accurate evaluations that match other software evaluations.

15. What features are you planning to add to Beaver in the near future, and how do you envision these new features expanding Beaver’s capabilities for timber engineering professionals?

In the near future, we intend to make the calculations much faster so that coupling Beaver with generative design and multi-objective optimizations runs faster.

In the medium term, we intend to create an integrated model where connections can be assigned to the structure and calculated in real-time. We should also develop a feature that includes CLT analysis soon.

16. What challenges or trends in timber engineering are you preparing Beaver to address moving forward?

There is still a lot to be explored in terms of interesting geometries that can be derived from full-computational workflows. The existing examples are already producing interesting designs, and we believe there is much more to come. Some of our partners are currently working on their PhD’s, and although the dissertations are not related to this project, there is certainly some overlap in the fields of research.

- Thank you very much for your time!

Thank you for letting us tell our story as well!

That's it for this new edition of Getting to know... Don't forget to visit Beaver on Food4Rhino and follow their company on LinkedIn.

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/08f137b6ba/cover.webp)