Computational design is rapidly replacing traditional design in many industries. Over the years, designers have built our physical world according to the characteristics of every object, from a basketball to a shopping mall. Today, computational design is changing this design process and thus becoming popular in many fields, from the automotive industry to architecture and apparel. In this article, we will discuss what computational design is and what its applications are.

What Is Computational Design?

Computational design is a design process that involves algorithms and coding instructions. It emphasizes defining every step of the process that leads to the formation of an object.

The concept of computational design is not new. It has been used in industries for a number of years now, but over the past decade and a half it has slowly built up to where it is today. Many different industries all across the globe have adopted it as their preferred solution for how to improve their design processes.

It includes variables, logic, and an end product that is produced automatically through running computer code. This is in contrast to designing an object on a traditional drawing/modeling tool.

Generally, computational design includes the following concepts:

- • Parametric Setting : Designers feed variables and parameters in the form of logic into the machine.

- • 3D Prototyping Tools : These allow designers to visualize the parametric scenarios through 3D models.

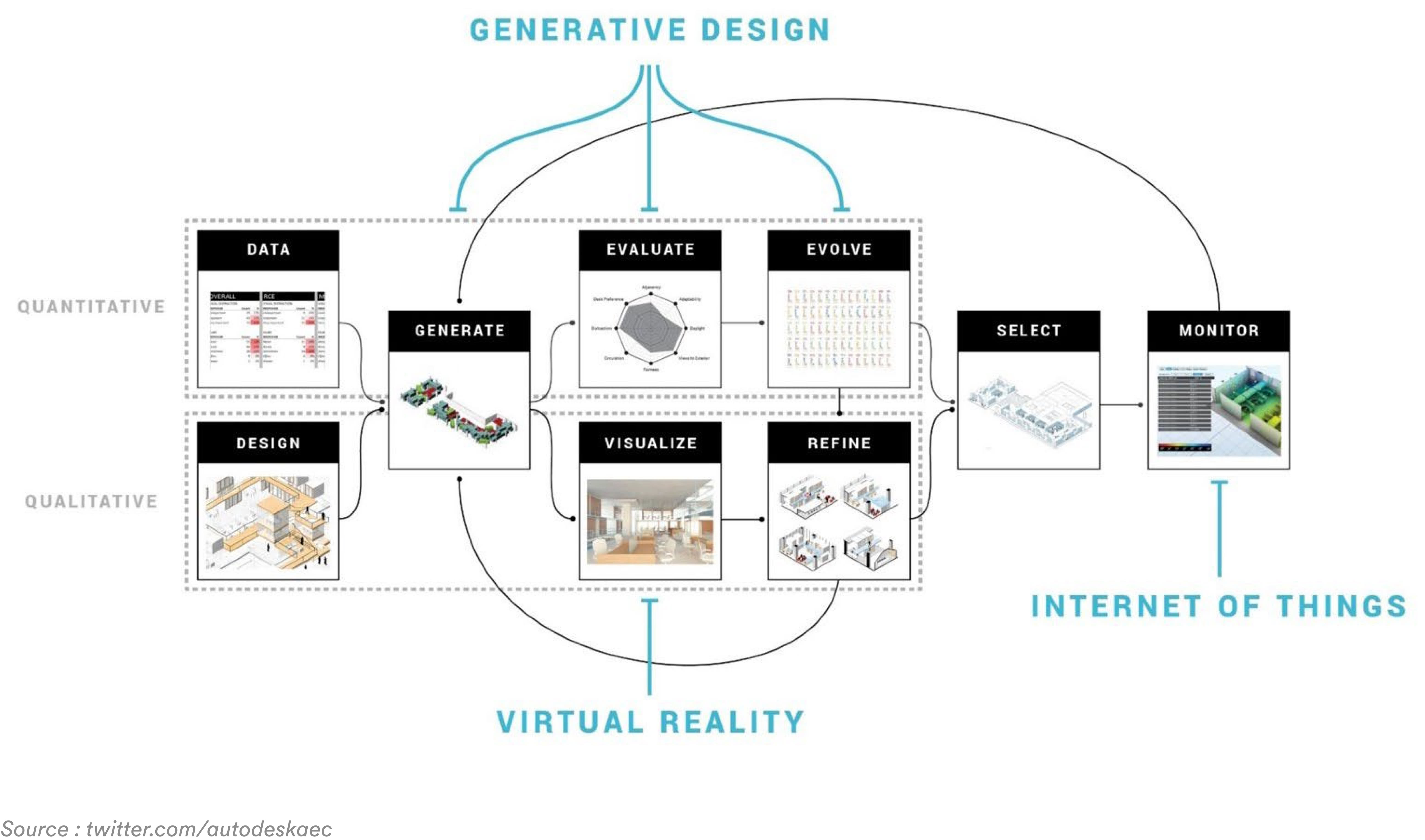

- • Generative Design: This enables machines to go through hundreds of designs, learn them, and create a best-suited design for the given problem.

- • Processing Power: Harness extensive computational power through the latest next-generation processors and cloud-based servers.

- • Big Data: Utilizing the abundant amount of digital data present today to generate new designs.

What’s Different About Computational Design?

The future of design is computational, and designers should get ready to harness its true potential. In 3D printing, CNC machining, and other manufacturing processes , computational design technology is changing it at a fundamental level.

So, what is different? An important concept to keep in mind is the “generative process.” Traditionally, designers have used modeling software and tools to sketch their ideas for different objects. These designs are then implemented to form concrete realizations. The generative process starts from the designer’s capability and creativity.

Now, with computational design, the generative process is handled by computers or machines. The designer instructs a machine through input parameters to form a particular output. Since the generative power of a machine is far superior than that of a human being, the benefits of using this approach can dramatically shorten different processes, such as design iterations.

To fully benefit from this computational power, a designer must understand the nuances of computational instructions and algorithm development. In other words, a designer's work today is less about designing and more about creating logic and defining parameters. Computational designers are those developing skills to better operate the machines producing designs.

Understanding The Computational Process

By understanding computation, we mean to understand machines. To be able to instruct machines, designers should know how a machine operates. They need to know its architecture and capabilities.

The generative process of a machine is different from a classical designer’s generative process, as discussed above:

- • A machine can repeat a process again and again.

- • It can continuously check a certain condition and perform a certain action repetitively.

- • It can stop at once when a slight error occurs.

This workflow is quite different from manual design work. Machines are capable of increasing design output exponentially. But all this is possible only when the machine is instructed correctly. This means a designer should know how to develop algorithms and make them work for a design flow.

Which Software Can Be Used For Computational Design?

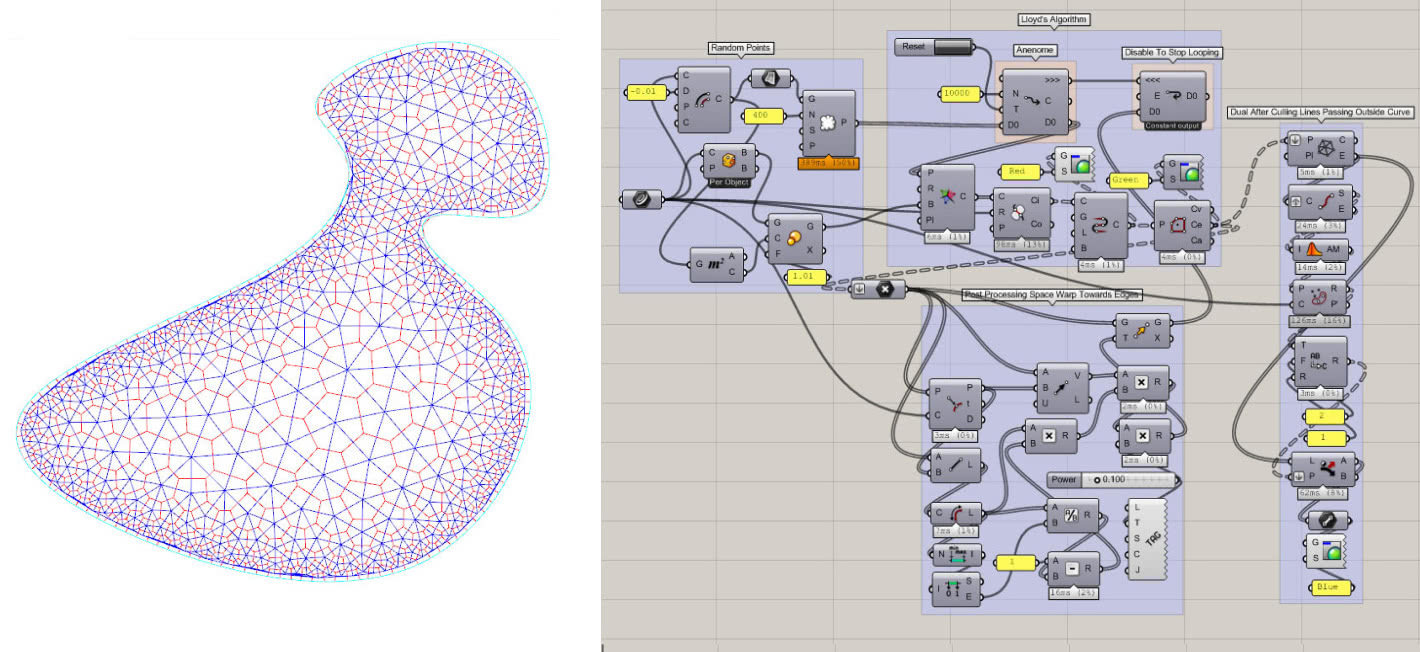

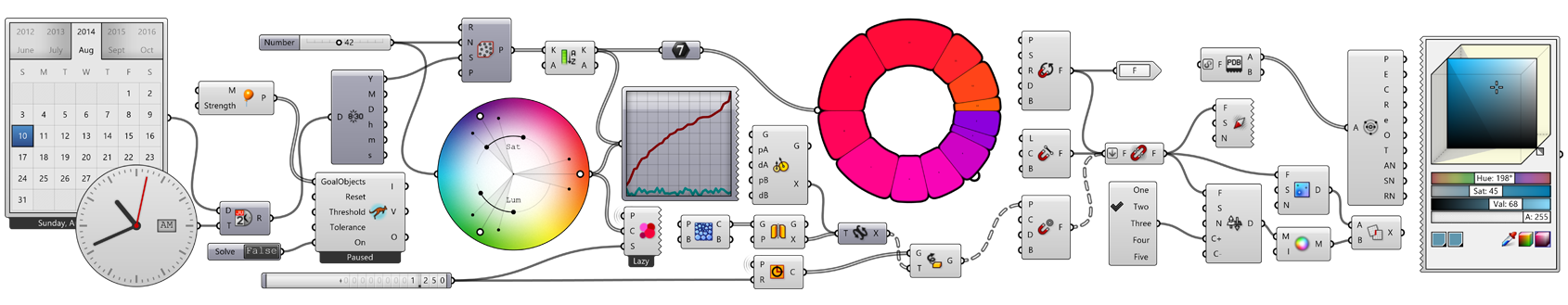

There are many options when it comes to software with computational design capabilities. From Siemens NX to CATIA, Fusion 360 and more. But by far the most widely used is Rhinoceros 3D and its plugin Grasshopper.

Grasshopper enables users to view and modify all of the material properties of rendered objects in real-time. With this powerful tool, users can adjust values such as color, roughness, height and display curvature effortlessly without having to create complicated files.

The plugin includes features such as a fluid and interactive animated interface that helps users have a better understanding of their surroundings while they are in design mode. Furthermore, the direct integration to Rhinoceros 3D provides users with the ability to view and edit their models in real-time.

Furthermore, it has a vibrant developer community that is constantly improving the ecosystem by creating third-party plugins that enhance what can be done with this software.

What Are The Applications For Computational Design?

Computational design can make a difference to anything from the design of furniture to the construction of buildings and bridges. It is an essential tool for designers and engineers as it speeds up and improves the design workflow on many levels.

In 2015, MX3D started working on the first bridge built through computational technology. This bridge, situated in Amsterdam, was designed, prototyped, and developed through the latest computational technologies, including robotics, machine learning, and 3D printing.

The process included four robots and six months of printing to complete a 41-foot bridge from 9,920 pounds of stainless steel. When using computational technology to design structures like this, architects feed input parameters to the software, including the constraints and logics. 3D designing helps architects to visualize the output against the set parameters. Moreover, the process becomes automated for the same parametric situations.

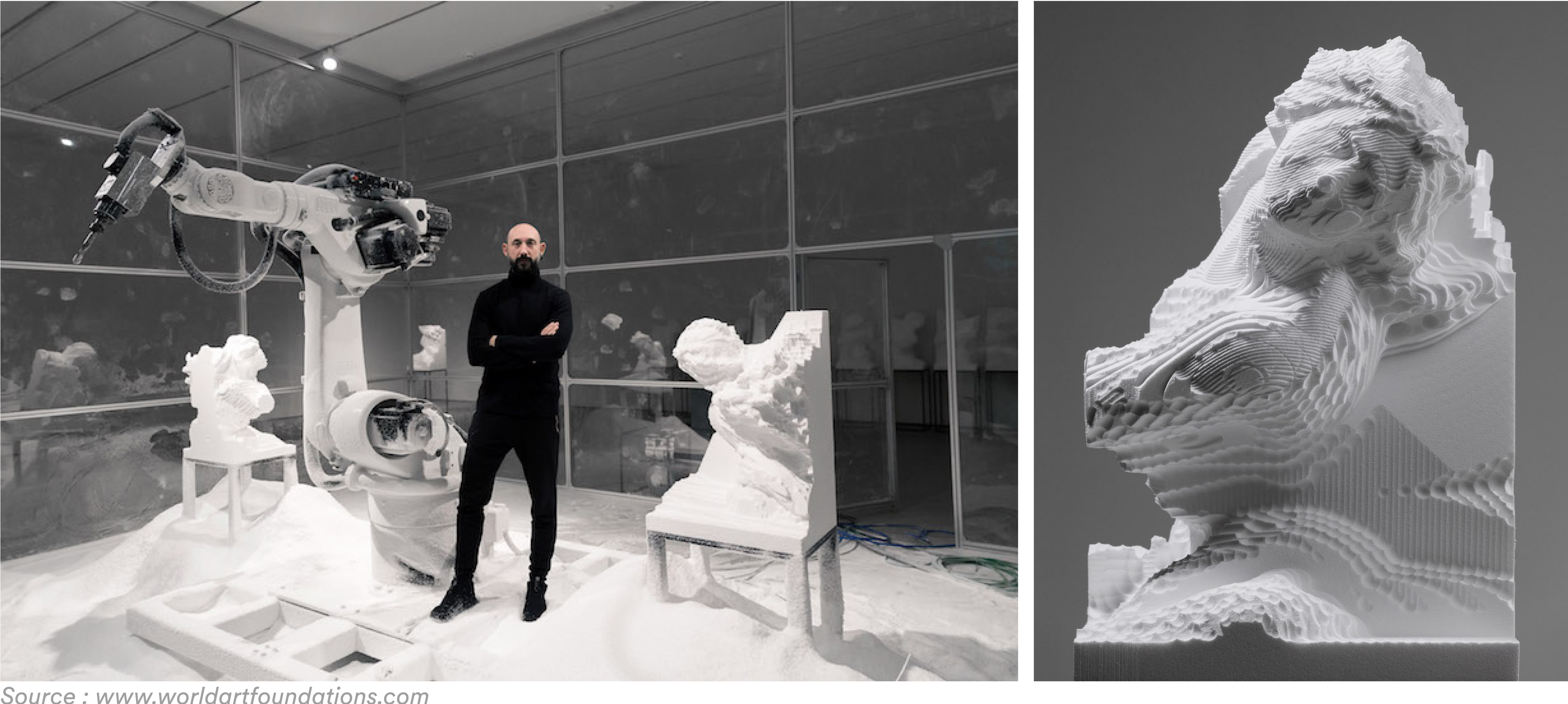

Today, architecture, the arts, and digital products all use computational technology in one form or another. Artists extensively use AI to realize their creativity. Computer algorithms are enabling artists to explore ancient art and give them a whole new modern essence. A sculpture factory by the artist Quayola is one such example of the fusion of art and computation.

But applications don’t certainly need to be so complicated as full-sized 3D printed bridges or sophisticated pieces of art. Computational design has become a very popular choice for many industries, such as Furniture, Jewelry and Interior Design, due to its efficiency.

Companies like Unruh Furniture , Nove25 or Shapelamp are leveraging the power of computational design and cloud computing to produce powerful online configurators that their customers can easily use to customize their product before a purchasing decision.

The Future Of Design

Computational design and present computational technologies have changed the contemporary approach to design, be it a building or a piece of art. Moreover, computational design promises huge potential for solving problems faced by the human race, including global warming, energy crises, and healthcare needs. At this point, it’s safe to say that the future of design is computational.

/f/92524/1423x870/d156144ad4/blog-header-cd.webp)