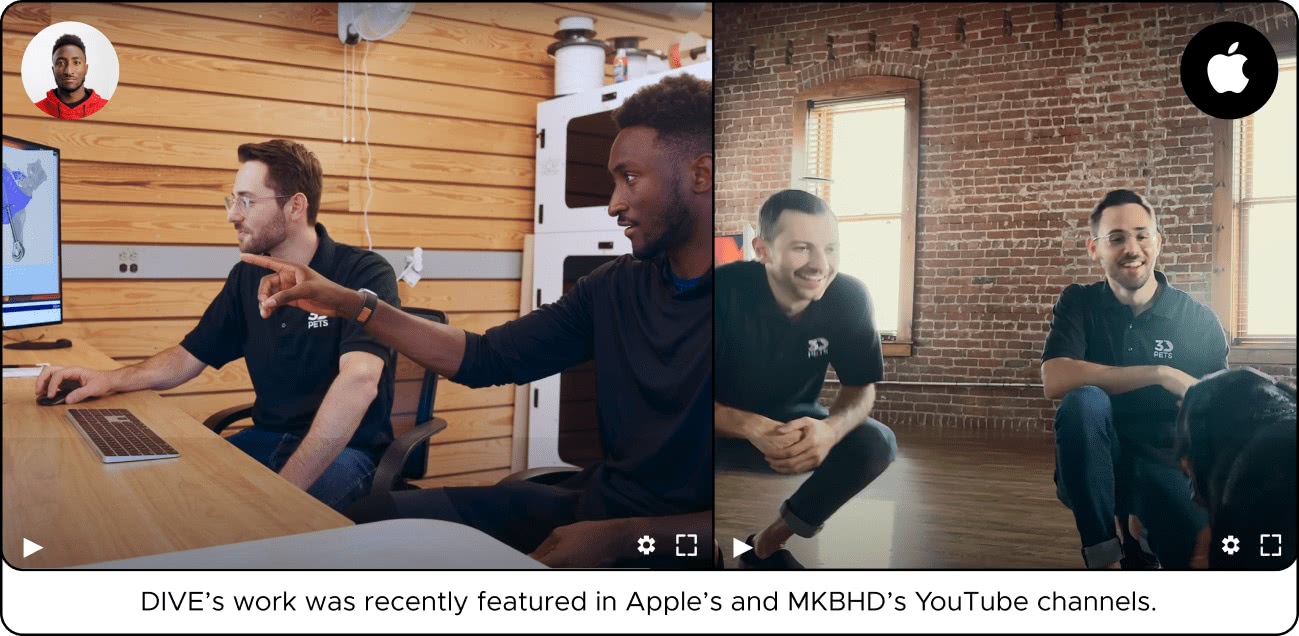

In this interview, we had the opportunity to sit down with the team behind DIVE, a New Jersey company dedicated to accelerating the adoption of Additive Manufacturing across different industries. In recent years, they’ve been featured on renowned websites such as Wired, 3dprint.com, and even CBS News, and recently, their brand 3DPets was featured by Apple and MKBHD on their YouTube channels.

DIVE's expertise lies in helping businesses integrate and leverage the benefits of 3D printing and assisting 3D printing companies in reaching new audiences through customer success storytelling. With a strong focus on industrial design related to additive manufacturing, DIVE is at the forefront of this innovative manufacturing technology.

Today, we will explore their mission, team members, the industries that can benefit from 3D printing, the significance of 3D printing in today's world, and their journey into consulting with companies about additive manufacturing.

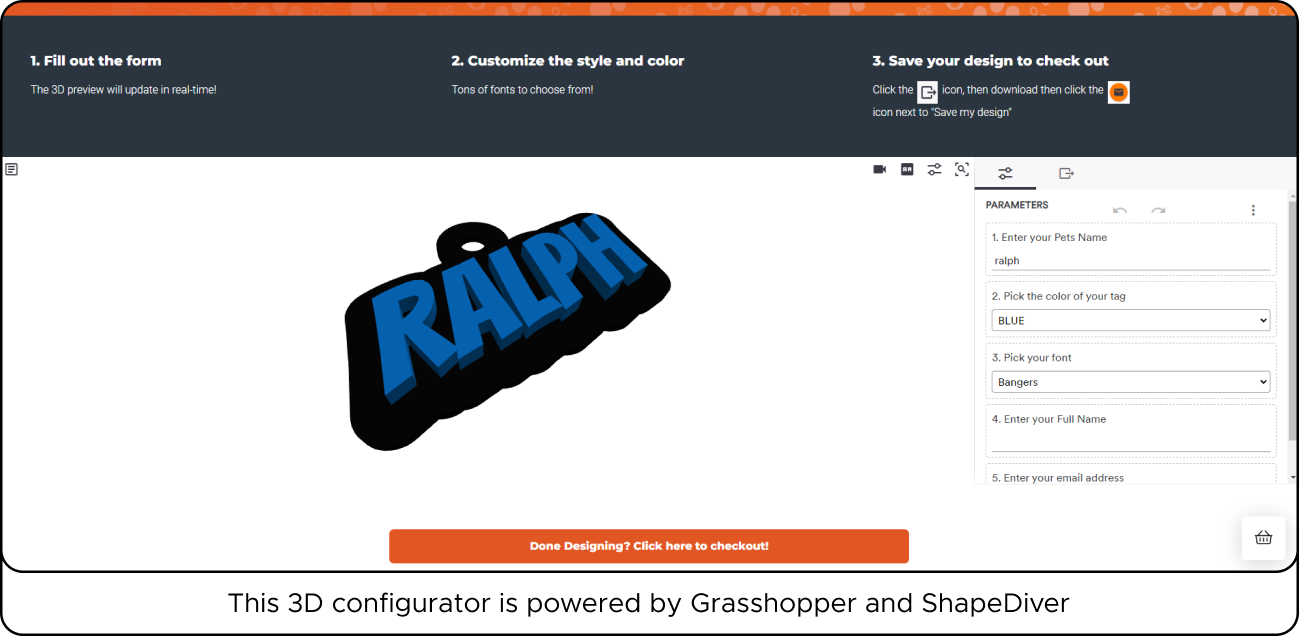

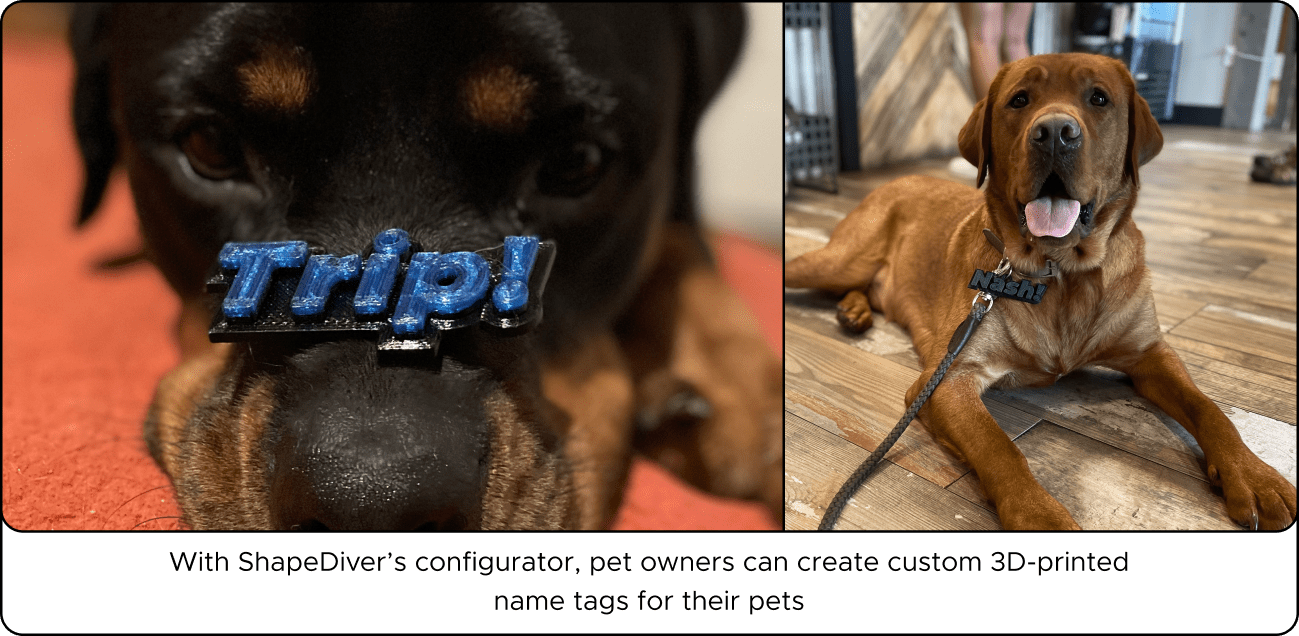

During our conversation, we understood DIVE’s unique approach to helping businesses navigate the complex landscape of 3D printing. We delved into case studies that showcase their expertise, examining how they have successfully partnered with clients to bring their visions to life. Furthermore, we discussed the impact of DIVE’s own pet brand, 3DPets, and its collaboration with ShapeDiver in spreading awareness of the benefits of parametric design and additive manufacturing, including a small project involving Grasshopper and ShapeDiver, used to create an online configurator for 3D-printed dog tags.

Lastly, we learned about DIVE’s passion for working with companies in the 3D printing space and their commitment to staying up-to-date with the latest advancements in production technologies and workflows. Let’s DIVE in!

______________

1. Can you provide an overview of DIVE and its mission to accelerate the adoption of 3D printing across industries?

Our backgrounds are rooted in industrial design and the development/manufacturing of consumer goods. That industry was very saturated and becoming very undervalued. We wanted to make a name for ourselves and be a leader in a specific industry while sticking with our creative roots. We pivoted in 2021 as our pet prosthetic brand, 3DPets, was starting to grow and exemplify unique ways 3D printing can be used for production.

We started offering consulting with companies wanting to implement 3D technologies. What we realized is that the 3D companies (both hardware and software) were struggling to explain and show how their technologies could benefit different consumers. It felt as though they were trapped in a bubble and needed someone to help pop it; that's where we stepped in. Alongside the consulting, we are also heavily rooted in marketing for Additive Manufacturing companies and showing how combinations of technologies can transform archaic ways of making products.

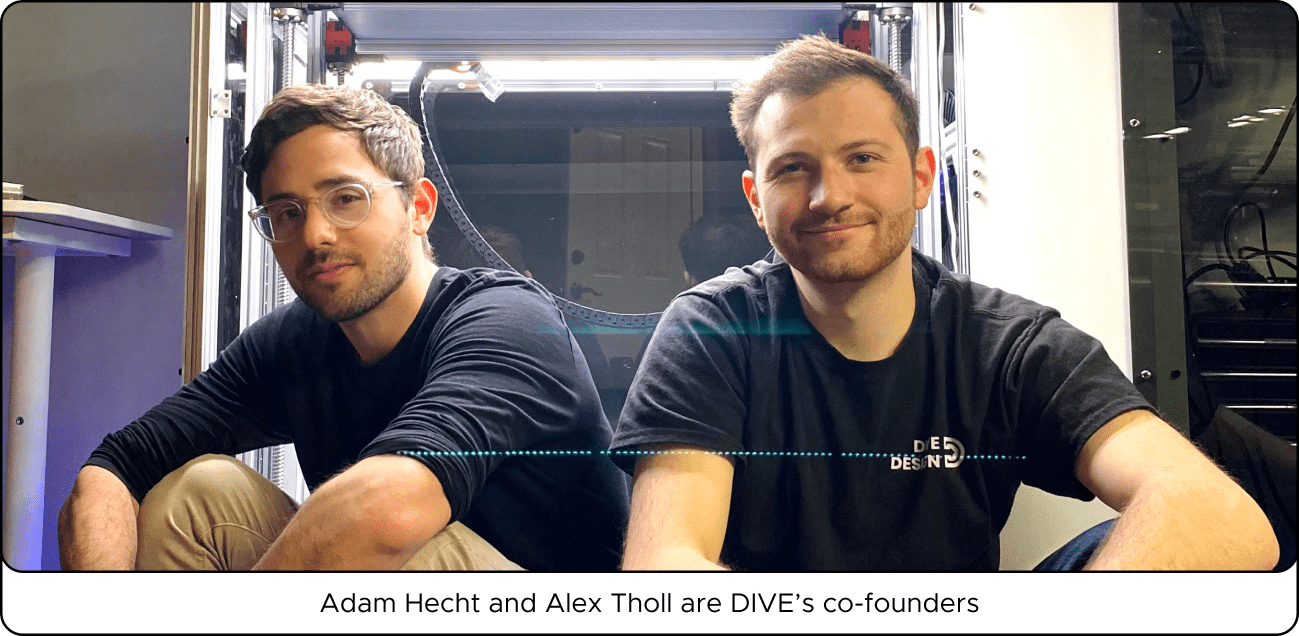

2. Who are the key members of the DIVE team, and what are their areas of expertise in relation to additive manufacturing?

Adam Hecht and Alex Tholl are the co-founders and come from Industrial Design, Medical, and Business backgrounds. Adam is the director of AM Marketing. He not only understands and uses these technologies, he helps our clients talk about them as well as implement them. Alex is our CEO and oversees operations as well as our pet prosthetics business, 3DPets. Vincent Zigarelli is our Lead Industrial Designer. He brings ideas to life through conceptualization, CAD, and prototyping through AM.

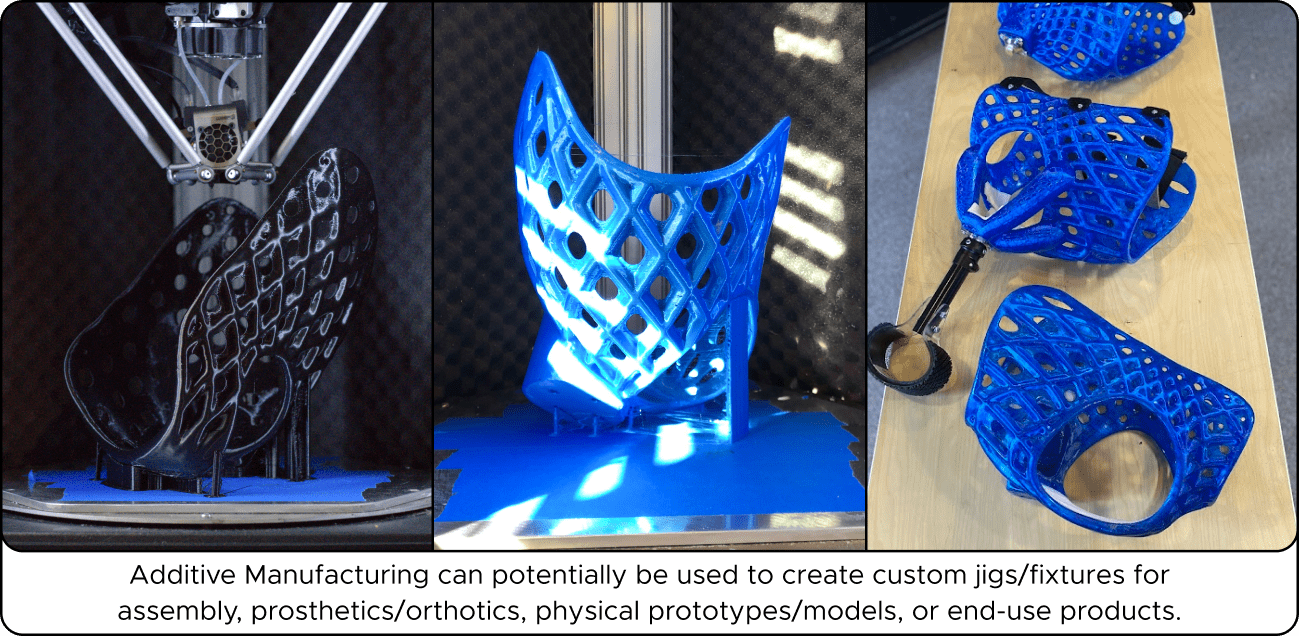

3. Which industries can most effectively leverage the benefits of AM, and how does DIVE help businesses in these industries navigate and access those benefits?

To some extent, any business could potentially benefit from using AM, whether it be a jig/fixture for assembly, prosthetics/orthotics, physical prototypes/models, or end-use products. There are big opportunities with one-off custom products that a company makes many of. Take shoe insoles, for instance. Every foot is different. If you want the perfect fit, you need to take a mold of that person's foot. Now, this is where the power of combining technologies takes place. You can leverage 3D scanning to scan the foot, a custom software tool like ShapeDiver to auto-trim the scan, and then a 3DPrinter to print the insoles.

4. Why do you believe 3D printing is essential for many industries?

3D printing greatly reduces the barrier to entry for innovation and product development. You can have an end-use product in a matter of hours now. With speeds increasing and material options advancing, we see it as a powerful force against more traditional manufacturing processes like milling or injection molding.

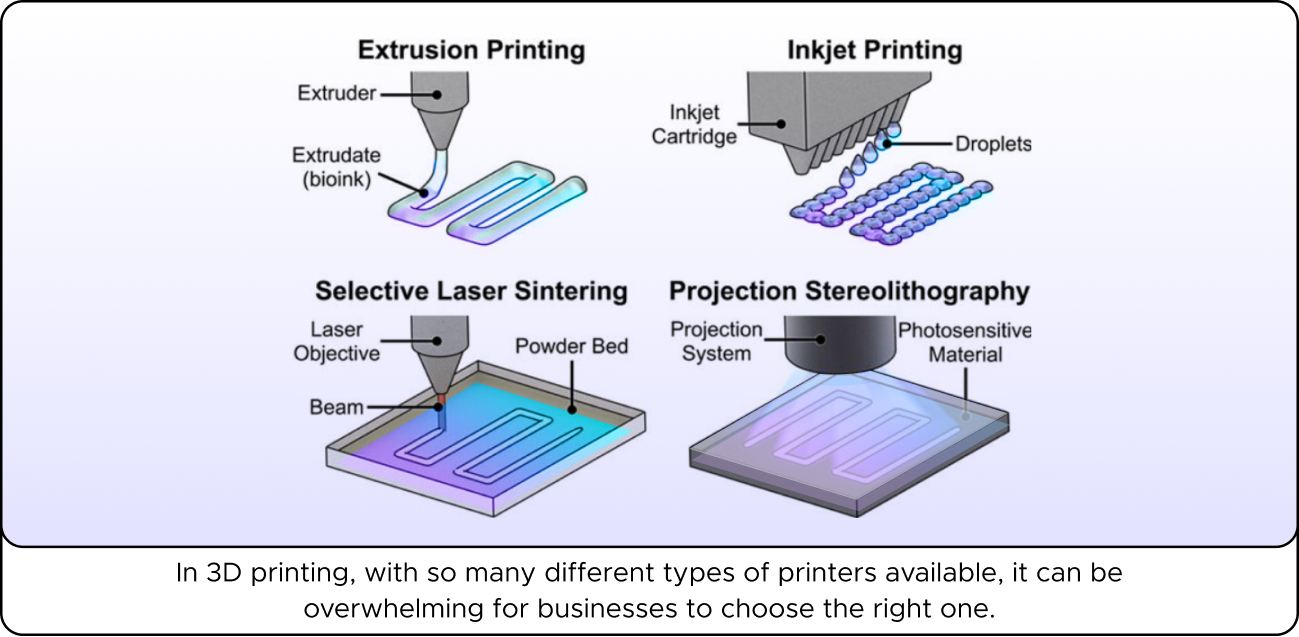

5. What are some of the main challenges holding businesses from adopting this manufacturing technology?

This is an easy one, the lack of understanding. This is unlike a paper printer, which you can set up at home and click print on your screen. There are hundreds of types of 3D printers, compatible materials, price points, etc. It's too overwhelming for many. That’s why the consulting arm of DIVE is so critical. We want to help as many businesses understand the benefits and make an educated, unbiased choice when it comes to implementation.

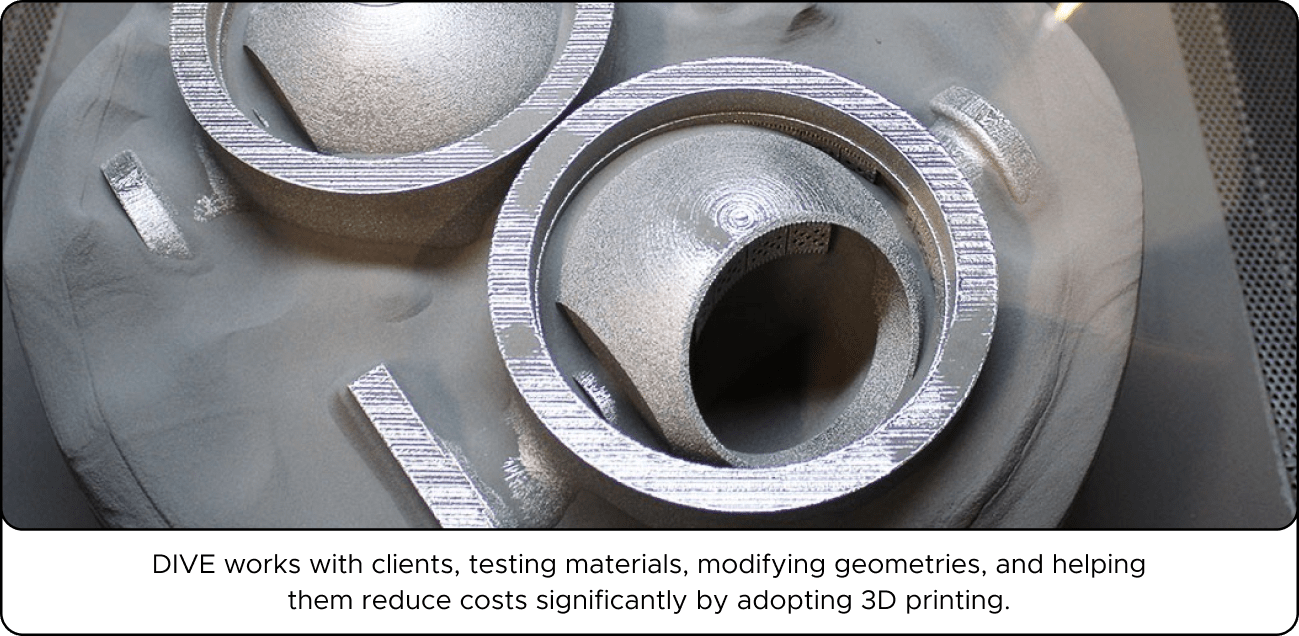

6. Can you share a specific example or case study where DIVE helped a company integrate and leverage the benefits of 3D printing?

There is a company in Pennsylvania that builds waste treatment valves. It’s a unique business that currently spends a great deal of money on cast metal valves. Over the course of a set of months, we were able to work with them, test materials, modify geometries, and help them reduce costs significantly by printing the valves.

7. How did DIVE realize the potential of consulting with different companies about additive manufacturing? Was there a specific moment or realization that led to this focus?

As mentioned earlier, it was catalyzed by 3DPets. People were enamored that such a device could be built using 3D printing. We also saw the opportunity for the AM companies to use some of these unique uses in their own case studies and marketing. It helped people wrap their heads around the technologies in simple yet profound ways.

8. How do you use customer success storytelling to help 3D printing companies accelerate adoption and reach new audiences?

Many companies that are already using AM are under strict NDA with the manufacturers, so it makes it very difficult for them to talk about some of the cool ways the tech is being used. We found that many of the companies we are working with since they are more design-driven than engineering-driven, are open to sharing their stories.

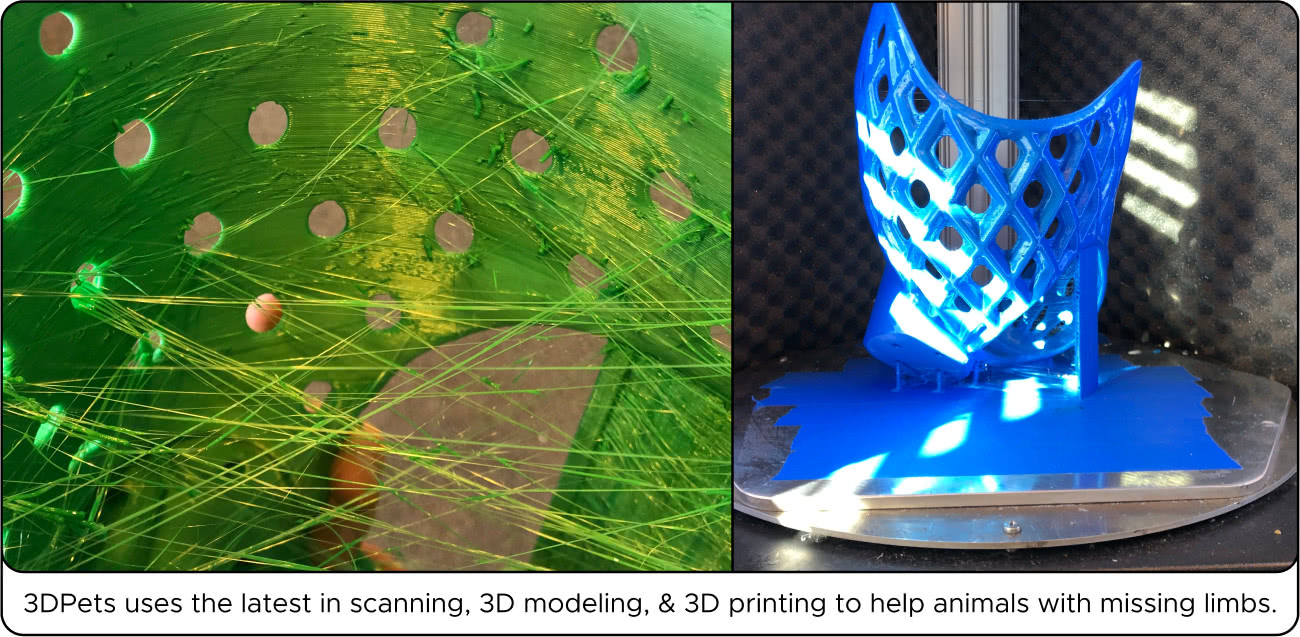

9. What is 3DPets, and why did you feel the need to start this brand?

3DPets stemmed from a consulting job that DIVE did years back. The product came to life and was worlds better than the hand-fabricated version that was being made. In fact, that was the only way they could be made, by hand over the course of 15 hours.

We reduced waste significantly and brought the process down to 5 hours. The client ended up going in a different direction, so we decided to partner up with some amazing orthotists/prosthetists and bring it to life. 2 years later, the brand is one of the leaders in the space and the only one utilizing AM technologies.

10. Can you tell us more about the name tag online configurator created for 3DPets? How can this contribute to explaining the benefits of parametric design and additive manufacturing to more companies in other industries?

Many families reach out wanting to support 3DPets, and while we have shirts for sale, we didn't feel like that exemplified what the technologies we were using could do. We had the backend component but needed software to bring it to the web for anyone to use while keeping great UX/UI. That’s where ShapeDiver came in.

11. Why were Grasshopper and ShapeDiver the right choice for creating this online tool?

Grasshopper gave us the ability to create the name tag generator, allowing people to see their pet's name tag being generated in seconds and eventually get 3D printed. The problem was none of our clients would have Grasshopper, so we needed a tool to bring it to the web and create a unique customer experience at the same time. ShapeDiver was the only company we trusted to do that.

12. What are some unique challenges DIVE faces when working with companies in different industries to integrate 3D printing?

The biggest challenge is always figuring out which AM technologies to combine. It’s very seldom just “finding a printer” or “finding software”. It's a combination, and you have to help your client understand what their options are, how to design for them, and most importantly, implement and benefit from them.

13. What do you like the most about working with companies related to 3D printing and helping them explore the possibilities of additive manufacturing?

It’s always a unique opportunity. Every company has a different problem they are looking to solve using AM, and that keeps things interesting and always forces us to stay on top of new developments and releases of AM tech.

14. How does DIVE stay current with the latest advancements in production technologies and workflows related to 3D printing?

Being a marketing agency in AM gives us a leg up, but also, being present at all of the related trade shows has been tremendously impactful. We recommend this to all people in the AM industry. Lastly is LinkedIn. We are so involved in the community that we always see the latest and greatest.

15. What’s the best way to get in touch with your team?

The best way to reach DIVE is by email, info@divedesignco.com , or head over to our website, check out our work, and fill out a form!

- This has been great! Thank you for sharing your story with us.

Thank you as well for this opportunity!

That's it for this new edition of Getting to know.... Don't forget to visit DIVE's website and Instagram account.

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/414519a28a/cover-min.webp)