In this week's interview you'll get to know Tobias Fast, Head of Towers Division and Digital Practice Leader at Fast+Epp. He'll explain everything you need to know about Mass Timber, how it relates to prefabrication in the AEC industry, the differences versus a concrete-only approach, and finally how ShapeDiver allowed them to create an online tool called Timber Bay, which simplifies their costs and material estimations during their sales processes. Hope you enjoy this conversation!

1. Welcome, Tobias. Thank you for joining us today! Tell us a bit about your background.

Hello everyone! Thanks for having me here. My name is Tobias Fast. I'm and Head of Towers Division and Digital Practice Leader at Fast+Epp.

I love building things and that’s why I studied Civil Engineering at the University of British Columbia and later in 2014, I studied Structural & Earthquake Engineering for my Master’s Degree.

After working with SOM in New York and Expedition Engineering in London, I spent much of my time living in Germany and working at Fast + Epp’s Darmstadt office. Through my work in four different countries, I have gained knowledge via a wide range of projects, including skyscrapers in Manhattan, tension structures at the London Zoo, and prefabricated egg-shaped timber cabins destined for the BC wilderness.

2. What is Fast+Epp and who do you work with?

We are a structural engineering firm based out of Vancouver, Canada. We also have offices based all over North America, namely New York City, Seattle, Edmonton, Calgary, and also we have an office that is very close to you guys based in Darmstadt, Germany.

Primarily, Fast+Epp works in the building sector providing services for buildings of all scales from Private Residential Homes to Large Towers for clientele ranging from Private Developers, Institutions like Federal, Provincial and Municipal Governments.

We work with all kinds of materials like Concrete, Steel, Timber, and Cross Laminated Timber or Mass timber being our area of specialty.

3. What are your service offerings and expertise?

At the core, we are a structural engineering and designing firm, but over the 30+ years of providing structural services, we have diversified our offerings. We currently offer Structural Design and Engineering for not only residential and commercial buildings but transportation structures too.

We have in-depth experience in providing structural design for Mass Timber buildings right from personal homes to large recreation centers. Leveraging our expertise in Mass Timber and Parametric Design, we have developed a series of web-apps under our Concept Lab in collaboration with ShapeDiver, for quick sizing of Mass Timber structures and elements. It was developed with the goal of combining the creativity of Architecture with the practicality of Engineering.

We also provide life cycle assessment studies for buildings, bridges, and exposed structures in regards to sustainability, structural optimization, and building physics.

4. Could you tell us about the recent trends in construction and the AEC industry in general?

With rising awareness regarding climate change and a quest for sustainable ways to build taller and better buildings, we are seeing a rise in the number of taller Mass Timber buildings popping up across North America.

Together with supportive building codes by the IBC and growing conscience about building materials, Mass Timber construction is the single biggest trend in the AEC industry and I feel it is here to stay.

5. What is Mass Timber and what factors are propelling its mass adoption?

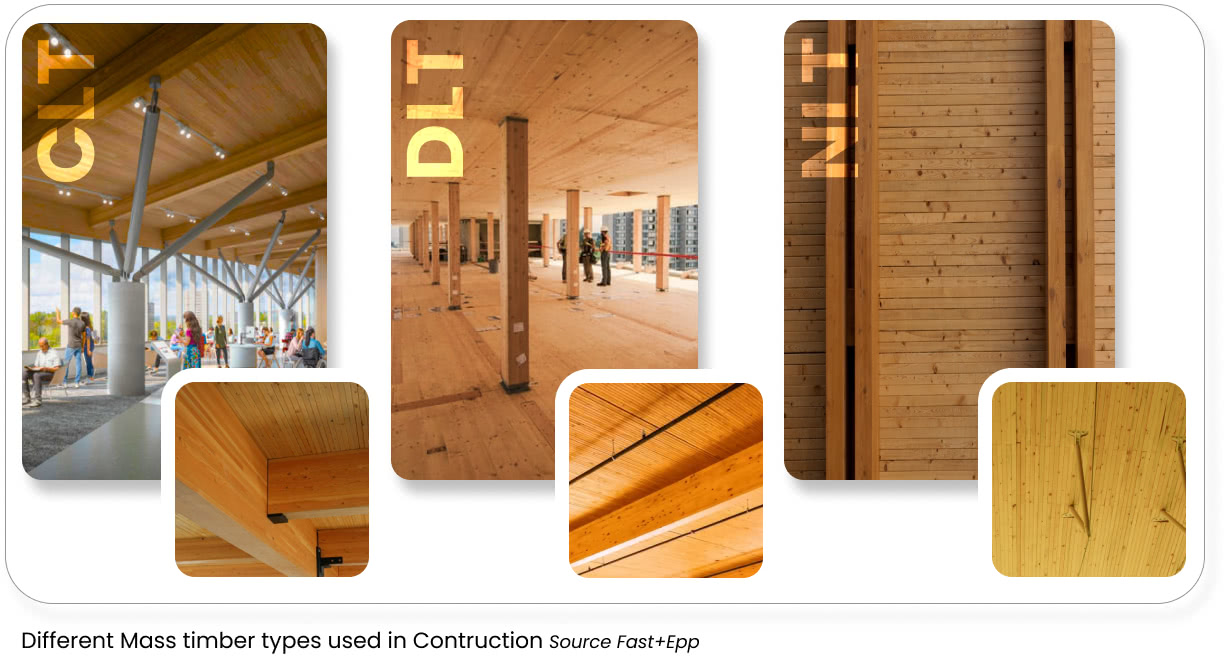

Mass Timber is a generic term that encompasses products of various sizes and functions, like glue-laminated (glulam) beams, laminated veneer lumber (LVL), nail-laminated timber (NLT), and dowel-laminated timber (DLT). But the most common and most familiar form of Mass Timber, the one that has opened up the newest architectural possibilities, is cross-laminated timber (CLT).

The "Mass Timber Movement", so to speak, started right where you guys are, Austria, Switzerland, and parts of Southern Germany. The first wave of timber products were Glulam or Glue Laminated Beams and Posts and was available in smaller section sizes with its application limited to small single family homes and residences.

Adoption in North America was relatively slow due to less to no supplier presence here for Mass Timber products and importing Mass Timber for prefabrication was not as convenient as it is today.

Fortunately, we have huge forest reserves here in North America and a long tradition of building with wood, but only on smaller scales. This, coupled with the influx of master carpenters from Europe and the introduction of wood products like Glulam and CLT. Mass Timber began to get more attention and gained more use in the building industry back then.

Today, Mass Timber is a much more common building material and is gaining more prominence by the day.

6. How did the "West Coast" become the "Chief Innovator" and leader for Mass Timber?

Several factors contributed to the rise of the West Coast’s dominance in the industry. For one, the willingness from the local authorities to allow engineers and designers to experiment and build with new technologies and materials combined with the building codes not being as restrictive as they are in Europe propelled the movement ahead to the next phase of research and studies being done at universities to find solutions for build higher and taller with wood and Mass Timber products.

Thus, willingness from the authorities, experimentation by designers and engineers, and supported by the research done at the universities had created a conducive environment that propelled the adoption of Mass Timber products further in much taller and higher buildings. Our Head Office in Vancouver, Canada, where I am currently, is also made with Mass Timber and Timber Prefabrication.

7. What is Timber Prefabrication? And what are the opportunities for timber prefabrication?

Prefabrication or Prefab is an incredibly fast and efficient construction technique that not only economizes the use of time, labor, and materials but also increases profitability over traditional construction techniques. However the term "Prefab" is highly misinterpreted as a technique to build an entire building off-site and then assembled on-site with all the services integrated with it - mechanical, electrical and others.

We need to understand that there are different levels to "Prefab" and these levels are largely influenced by the amount of risk a contractor or entity can take. Not a lot of contractors or suppliers are out there willing to take the risk of executing the structure, envelope, mechanical services, and furnishings all under a single roof. Here in North America, we do have some suppliers and it is often talked about on paper, but it's very difficult to get it done for an actual building.

However, Timber Prefabrication provides a very good starting point and helps in resolving the risk issue for all. With Timber Prefabrication, we are only talking about the structure and not about the services, envelope, electrical, and rest of things. This is especially easy to do for most contractors and builders as the risk and scope are manageable for them without it overlapping with mechanical, electrical, and others.

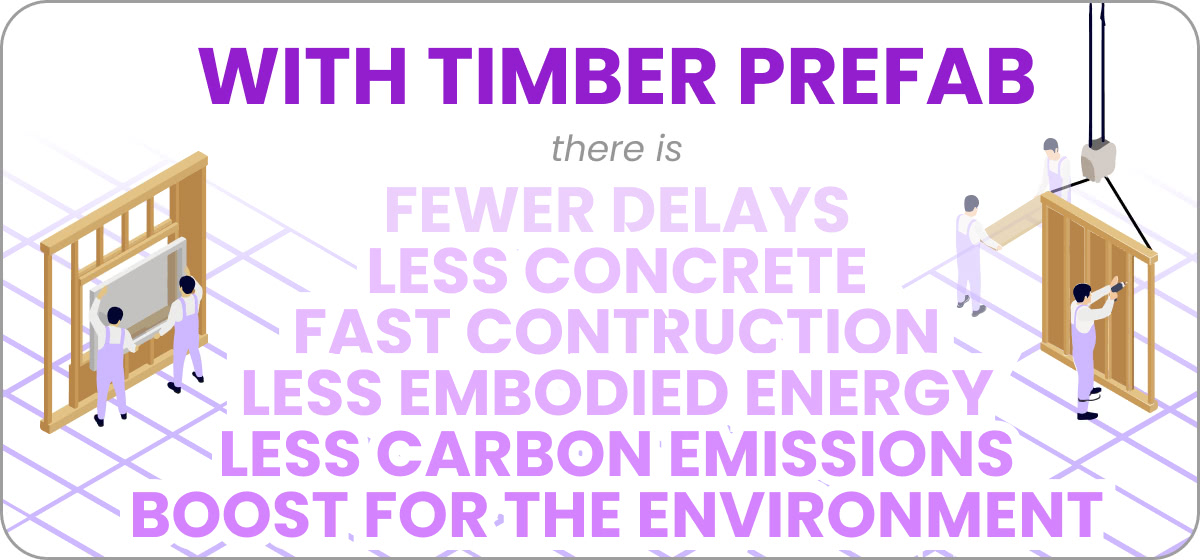

The Brock Commons Tallwood House is particularly a good example of how Timber Prefabrication can synergize the construction on-site as the 18 story building went up two floors every week! With Timber Prefab, there was fast construction, much fewer delays, fewer carbon emissions, and embodied energy, and less concrete, hence a massive boost for the environment.

All in all, even though the highest level of full-kit assembly is away, Timber Prefab is a good entry-level approach for prefabrication.

It’s only a matter of time before more suppliers and contractors come on board to make it possible. But we are having more and more conversations regarding "Prefab" with our clients and considering its numerous advantages, we feel that we are headed in the right direction with it.

8. Tell us about the negative effects of concrete on the environment and what is your approach towards the issue?

This often comes up in most of our conversations with our clients but only in some percentage of those conversations it is taken seriously, in terms of willingness to do away with the use of it in their project as a construction material.

The adverse effects of concrete as a building material is fairly well known and proven by various research studies documented over several years. The industry too has a fair idea of the number of carbon emissions they generate and their ill-effects on the environment and we’ve certainly had conversations with suppliers and manufacturers about finding solutions for reducing their impact on the environment, one of which is changing the concrete mix design ratios to use less cement and in turn reduce the impact of concrete.

That being said, the gains from the mix design are very minuscule and other solutions currently available in the market are not promising either. So how do we move ahead?

Well, the way we look at this particular problem is that we take a pragmatic approach towards it. Concrete is still bad from the sustainability and environmental lenses, however, it's still an incredibly useful material. The vast majority of buildings are made of concrete and the need for it can’t be controlled. What we can control though, is the amount of it. We’re never going to build a deep foundation structure or basement structure without the use of some concrete. We just need to know where to use it and how best to use it. Using each material where it's best suited for.

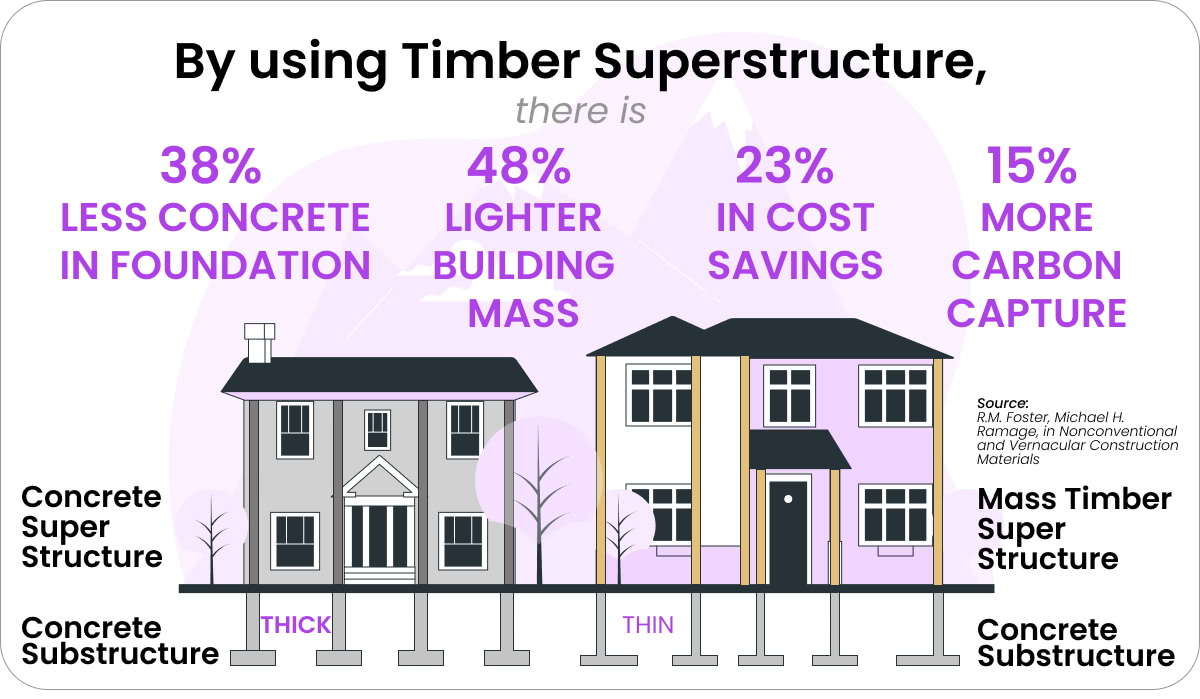

Another conversation around concrete is the need for densification. We need taller, higher structures and those structures need deep foundations made out of, you guessed it, concrete. To deal with the issue at hand, we promote mass timber superstructures that are made up of timber and some amount of supporting steel for buildings, like our office here in Vancouver. Here the superstructure is of timber and steel while the substructure is of concrete.

Of course, you can be a purist and do away with concrete at all. But for us, we take this pragmatic approach where we believe concrete is useful, where we shall best use it, and let’s reduce it where we don’t need it and use timber prefabrication as much as possible.

9. What timber is actually being used for construction?

When we talk about "using timber for construction", we generally mean man-made wood panel products that are made by arranging layers of wood in different patterns and held together by different materials. There are majorly four different types of wood products used in the construction of a building. They are glulam, CLT, DLT, and NLT. Glulam is not a new wood product, it has been in use for decades. Glulam is Glue Lamination of wood strips. The conventional wood is cut into thin strips and alternate strips are glued and bound together in various shapes and sizes.

CLT, DLT, and NLT are particularly new-age wood panel products. Unlike Glulam, CLT or Cross-Laminated Timber is made by alternate wood strips glued perpendicular to each other. Because the lamstock is going in two directions, it gets better structural rigidity and doesn't shrink in length or width.

DLT or Dowel Laminated Timber avoids using glue and instead uses wooden dowels to bind wooden boards together. These are used in places with high moisture variation throughout seasons as the boards combined with hardwood dowels form a moisture equilibrium due to their differing moisture content.

NLT or Nail Laminated Timber is just a modern name for what has been done forever in warehouses and factories, and used to be called mill decking; you just nail boards together. The aesthetics of NLT are a bit rougher, with that warehouse look that people want these days, without all the trouble of old warehouses.

10. Are you considering using "Material Passports"?

Certainly yes. Material Passports are a collection of data sets that can improve our current situation of raw materials crisis by providing a detailed inventory of all the materials, resources, and components of the product, as well as detailed information about their source location , extraction, and use.

Material Passport is a great step in the quest for a more circular economy, however, since it's a relatively new idea and no regulations have made it mandatory, enforcement is ineffective. That being said, here in North America, we do have "Environmental Product Declarations" or EPD which is eerily very similar to Material Passports.

EPD is basically a paper that provides information about the contents of the product, the amount of energy needed to transport it from its source to the job site, and vividly illustrates its sustainability data in regards to its procurement and use. With EPD one can easily review the entire sustainable and energy history of every material and product available on the market.

At Fast+Epp, we have extended this by creating internal logs about each building that we design in terms of its carbon footprint and cost to the environment. This is certainly not just Fast+Epp but we feel that Vancouver as a city has started to think in terms of its cost to the environment and how well we can reduce it. The initiative does not help in reducing carbon emissions by tons of margin, however, every tiny bit helps. This initiative has certainly led us to create better designs, both from a structural as well as a sustainability perspective.

11. How and why do you use ShapeDiver ?

The idea for a preliminary concept design tool, now known as Timber Bay, came as a response to resolve the observed redundancies in our workflow whenever a new timber building is conceptualized. The ShapeDiver platform helped us do away with the constant repetitive tasks of calculating each member's sizes and grades for various spans we propose to our clients.

With its computational abilities, we are not only able to calculate member sizes, but even able to visualize them instantly. This particular feature greatly improves our client experience as they no longer have to read a 2D PDF with a bucket load of calculations and instead can see a 3D visualization of the proposed design, instantly.

Another benefit of the computational tool with regards to timber construction is that it provides a fair amount of idea about the spans that can be worked with, different types of grids, preliminary material costs, and various other parameters that can be easily played around to arrive at the ideal solution.

What started as an internal productivity tool, now lives online as part of our Concept Lab. This ShapeDiver collaboration has made it easier to have a conversation regarding structure and material with our prospective clients.

We already have a considerable amount of hits on the web app, externally, and that has taken us a bit by surprise. But we do see its value in terms of shortened decision times, fewer human errors, and more productivity. A win-win for both the business and the consumers/stakeholders alike.

12. What are your future plans regarding this configurator?

Future plans would be to add the new PDF export and the new AR functionality of the ShapeDiver platform. Both features would be extremely beneficial for our sales team in their conversation with prospective clients as they can not only have a quick estimate of the building cost but can even have a quick visualization of the proposal. From a business perspective, we are witnessing tremendous value in our association with ShapeDiver!

- Thank you very much for your time, Tobias. This has been an excellent overview!

Thank you as well for having me!

That’s it for this new edition of Getting to know... Don’t forget to follow Fast+Epp directly at their LinkedIn and Instagram accounts!

<< Special thanks to Alex Walzer for his collaboration during the writing of this article. Alex investigates the role of entrepreneurship for and in AEC when utilizing nascent production technologies. He is a PhD researcher at the Chair of Innovative and Industrial Construction (Prof. Dr. Hall) at ETH Zürich - and can be reached at walzer.tech and @alexnikw on Twitter . >>

/f/92524/1200x630/ee2ad44529/fast-epp-header-shapediver-blog.webp)