After some years in the hospitality industry, Winston Ferguson decided it was time to start his own business. He set his eyes on the Furniture Industry as he believed there needed to be more progress in how furniture was sold online.

Soon after getting started with an MVP, the pandemic forced him to pivot and rethink his strategy. In this interview, we discuss the story and the decisions he had to make throughout his journey. We also discuss his tech stack and vision for his company.

1. Welcome! Tell us a bit about yourself. Why are you working in the Furniture Industry?

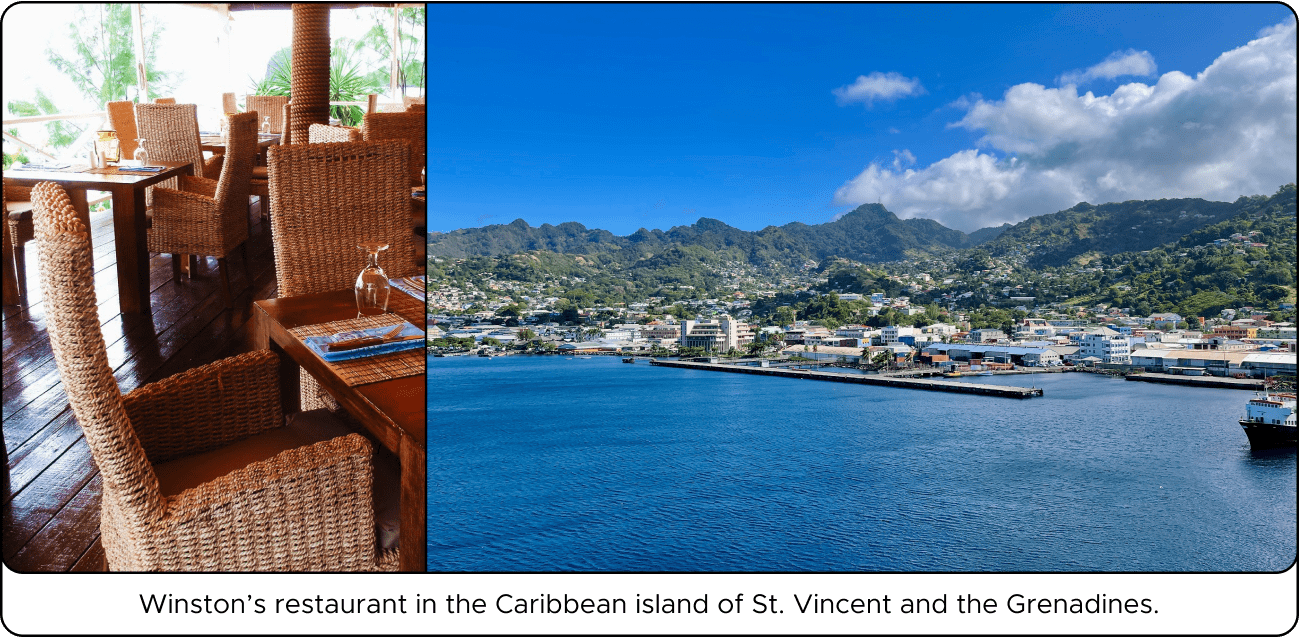

My name is Winston Ferguson. I’ve been living in the UK since 2017, but I’m originally from Vancouver, Canada. Growing up, my family had a furniture store, and I started my career working for a large international furniture brand. I then took a detour to the island of St. Vincent And The Grenadines in the Caribbean, where I opened a restaurant.

After about ten years, I felt it was time to get off the islands and out of the restaurant business. I was surprised by how little the furniture industry had evolved despite how much technology had advanced. So, I decided there was both a substantial challenge and an opportunity to rethink how furniture is designed, made, and marketed.

2. Saw & Sew: interesting name! What does it mean to you?

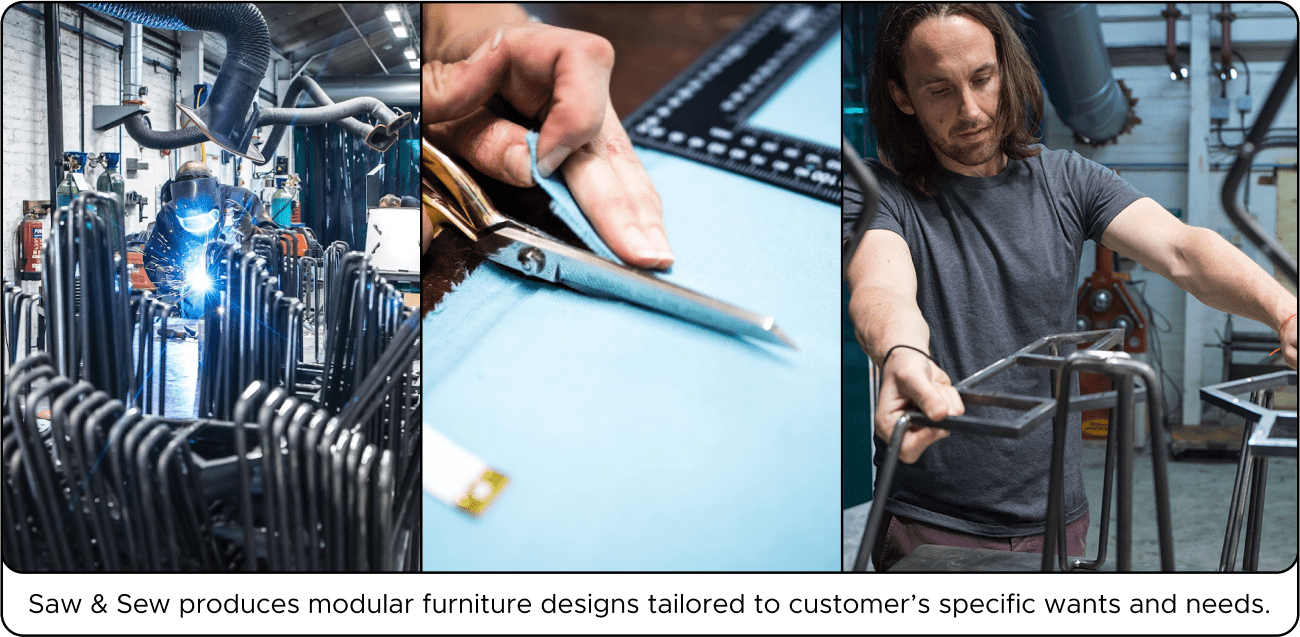

Literally, Saw & Sew is a reference to two furniture-related activities: sawing wood and sewing upholstery. But to me, Saw & Sew is much more - it’s my pursuit of a vision.

3. What's the back story to Saw & Sew?

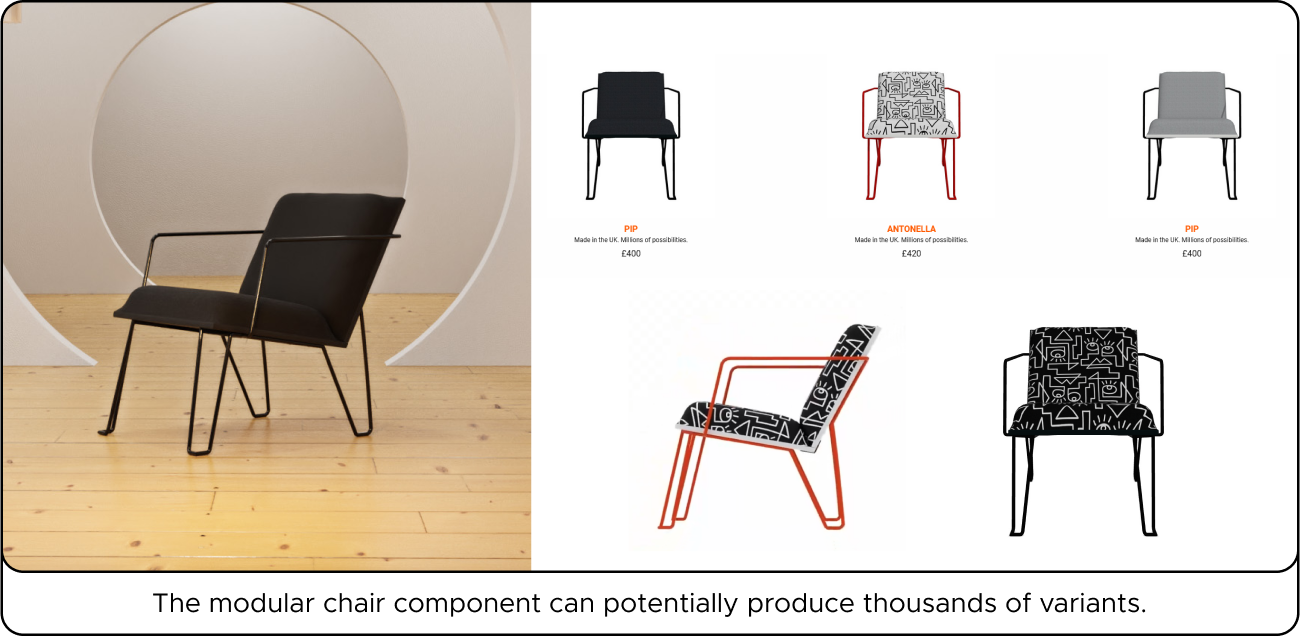

The vision has always been locally made-to-order furniture for the mass market. The company was originally focused on developing modular components to achieve this. We launched a minimum viable product, a chair component, but couldn’t find a suitable platform to market our furniture and realize the immense customization options afforded by our concept. Then the pandemic hit, so we scaled everything back to focus on developing the technology internally.

I’ve designed and developed almost everything relating to Saw & Sew - building the company has been a matter of my time.

4. What’s your favorite part about working with the concept behind Saw & Sew?

The challenges it presents - coming up with solutions to things like:

- Marketing a design with thousands, or even millions, of variants.

- A product that adapts to where the consumer is geographically.

- Developing an effective customization process that isn’t overbearing.

Following that, you’re rewarded with an exciting design process. The concept excels at accommodating an immense product development schedule. It’s about exploring many ideas, gauging market reactions, and evolving. You’re not restricted to playing it safe because of the associated costs/risks in product development.

5. How did you learn about Grasshopper?

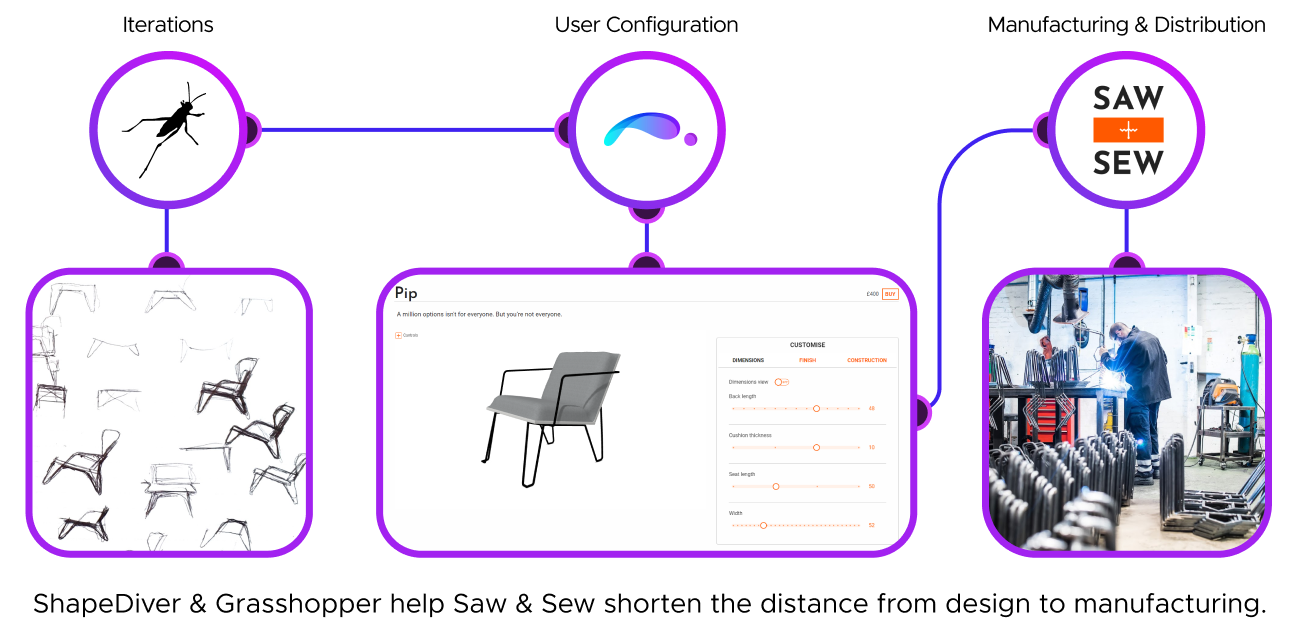

I have known Rhino since around 2018. I learned about Grasshopper after discovering ShapeDiver while I was googling for a solution that would let me create my online configurators at my own pace.

6. When did you realize Grasshopper was the right tool to power this online configurator?

When I discovered how flexible and capable it is. Not only can the design develop from its simplest origin, but what’s created is applicable in manufacturing processes - it’s not just a visual representation.

7. How is ShapeDiver involved?

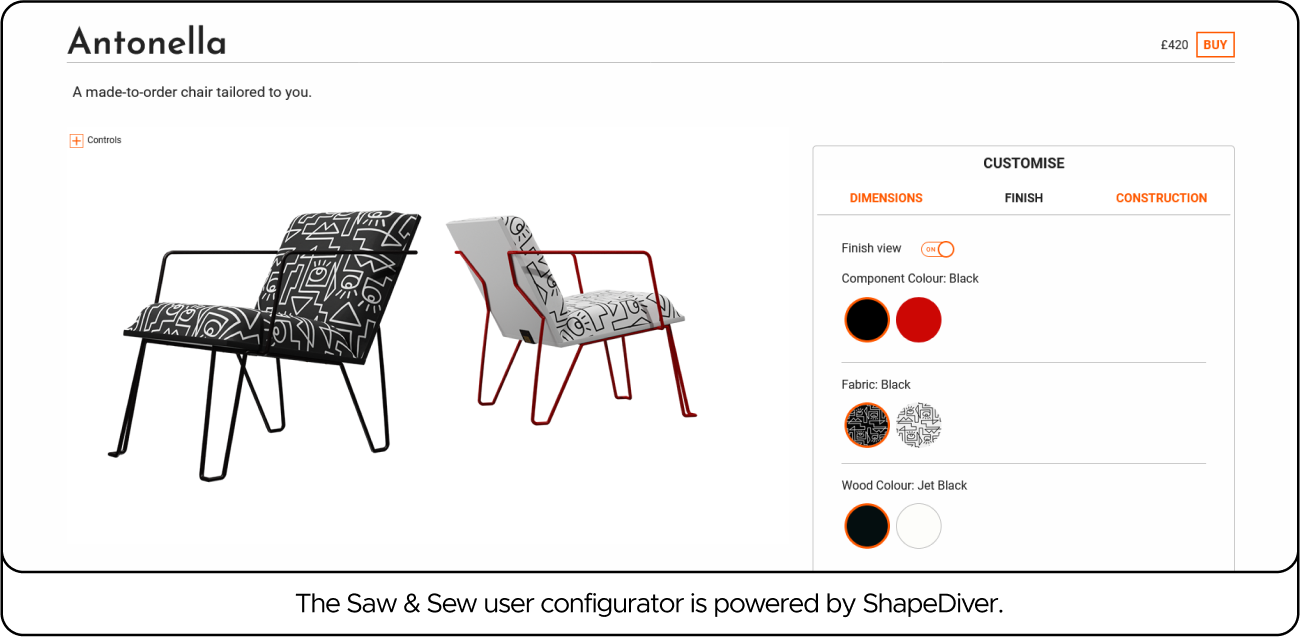

We use ShapeDiver for our online configurators. It renders the user-manipulated design and handles the creation of any necessary CAD files.

Using ShapeDiver means our workflow is synergetic across the entire vertical chain of processes. A single Grasshopper definition will create the 3D models for our visuals and, thanks to ShapeDiver, serve as a 3D configurator to potentially thousands of products, which can also be viewed in Augmented Reality.

8. What are other technologies involved in this project?

We use React.js for user inputs and to track the state of a user’s design. Our platform is built using Ruby on Rails and uses the proprietary metadata system we developed to relate goods and services for the creation of products via a configurator.

Additionally, we use Adobe Creative Suite to create texture maps and Blender for visuals.

9. You’re currently raising funds. What’s the vision for Saw & Sew in 5 to 10 years?

I want Saw & Sew to enable most consumers to have furniture that isn’t a compromise after a tedious process of searching inventories. Their home can feature exciting designs precisely tailored to their specific wants and needs.

We will become experts in technological processes related to user-generated products.

10. Can you give us a sneak peek into what products we will see in the future from you?

We’re launching a collection of textiles, and we have several more design prototypes in the works - including chairs, beds, and tables. Additionally, Saw & Sew is looking for local furniture, material, and textile makers to collaborate with so the platform will start to feature products from other designers.

In 2023, we’ll develop real-time algorithms for creating products based on a user session. In the future, it won’t be about the products you see from Saw & Sew but the products you see from you - even if you don’t even know you created them.

- This has been great! Thank you for taking some time to talk to us.

Likewise! Thank you for letting me share my story.

That's it for this new edition of Getting to know... Don't forget to visit Saw & Sew's website and LinkedIn profile.

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/5450d72c26/saw-sew-shapediver-grasshopper.webp)