Introduction

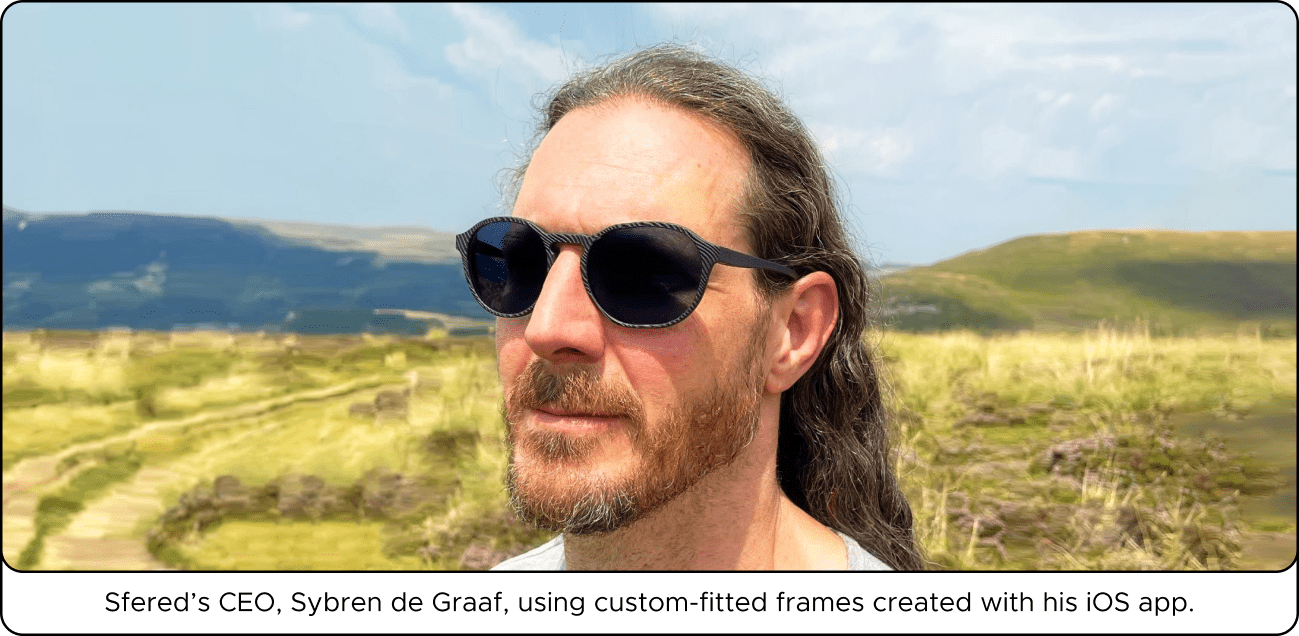

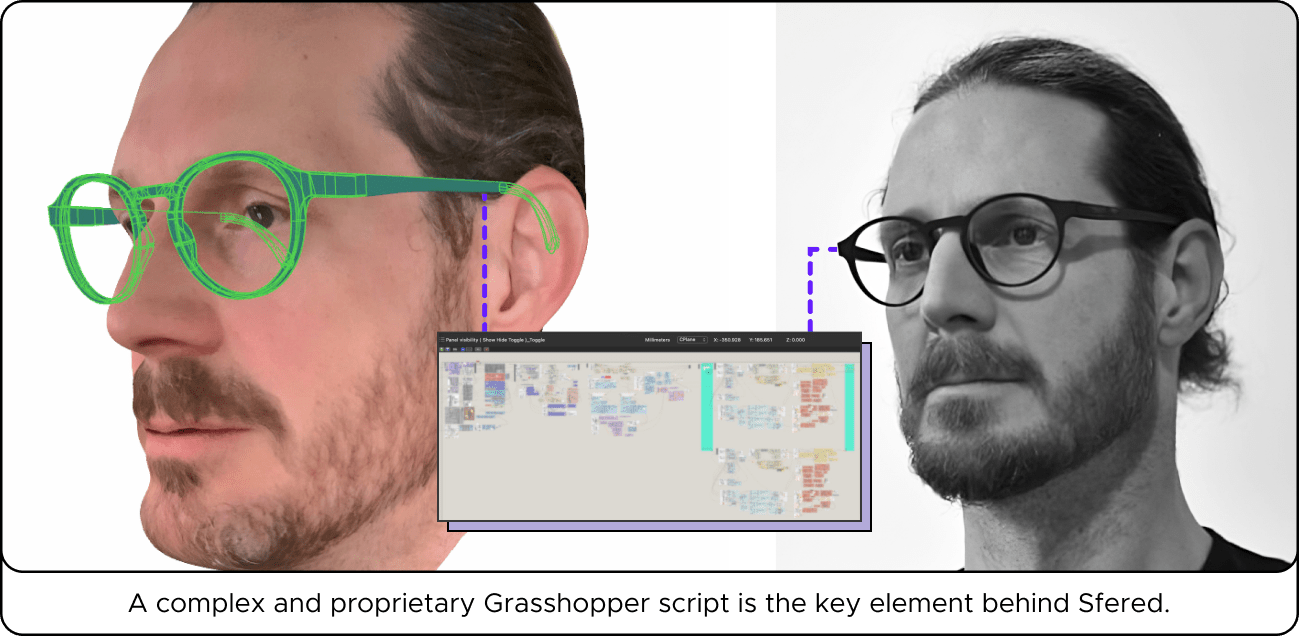

Sybren de Graaf, CEO and founder of Sfered, created an innovative solution for the eyewear industry using Grasshopper and ShapeDiver's infrastructure. With a background in architecture, Sybren discovered the potential of Grasshopper and used his design knowledge to create a revolutionary online service for opticians. Sfered's service allows for the customization of frames using a 3D parametric model placed on the client's scanned face. The result is a personalized and comfortable fit unique to each individual.

In this interview, we dive into Sybren's early beginnings, his early design influences, and how he discovered Grasshopper. We also discussed how his architectural background influenced his current path and when he realized the concept behind Sfered could be a good business idea. Furthermore, we explore how ShapeDiver helped him create this iOS application, the challenges he's faced so far, and what opticians say about the tool.

We also touch on the future of Sfered, the possibility of licensing this tech stack, and the future of product design and digital fabrication. Join us as we discover the story behind one of the most innovative solutions in the eyewear industry.

1. Hello, Sybren! Please introduce yourself and tell us about your background.

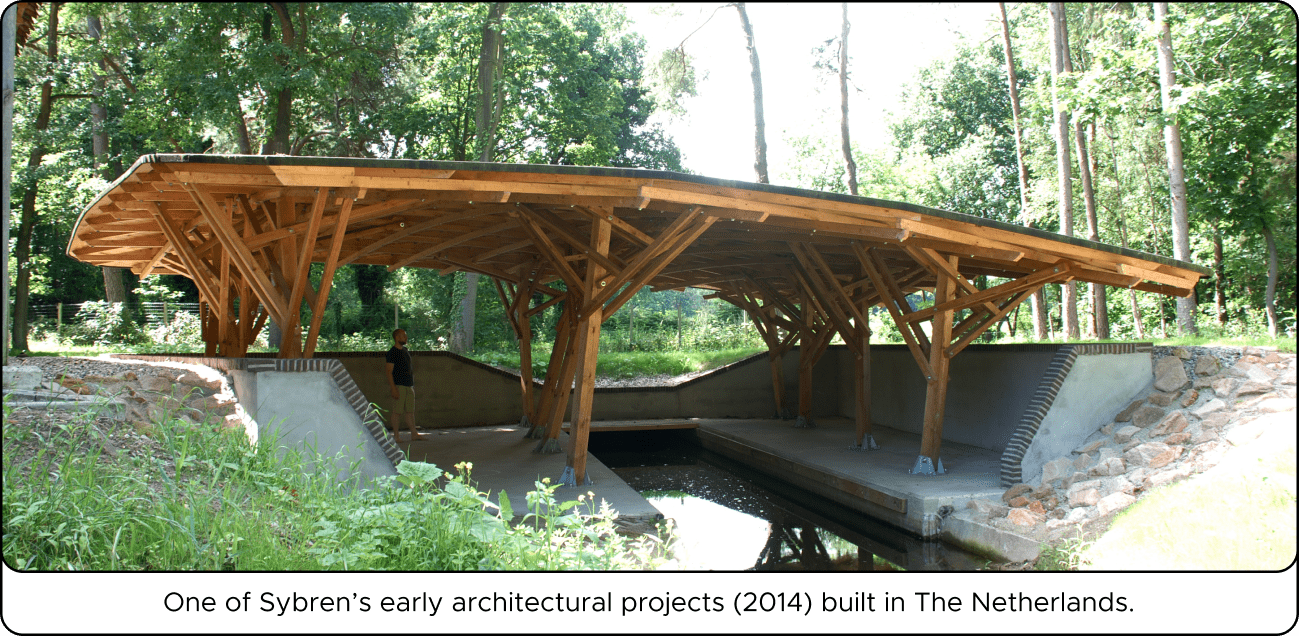

Hi my name is Sybren de Graaf. I was born in 1977 in Surinam and moved to the Netherlands when I was five. In 2006, I graduated from TU Delft and started working as an architect and inventor in Amsterdam.

I am fascinated by design, geometry, making things in all kinds of ways, programming, and then creating something unique out of these combinations.

For years I have been working as an architect on tools to support my design trajectories and explore new fields in architecture and design. This has evolved into craftsmanship, where algorithms, design, and making come together in realized buildings and objects.

Then, in search of my own self-made spectacle frame, I started the development of custom-fit frames on a whole new level that didn't exist yet.

2. Can you tell us about your early design influences and how they shaped your career path?

As a kid, I used to take apart, repair and modify things. In the process of altering my own living space, I made lamps and fixtures from strange objects I found and even removed parts of the wooden walls to make the somewhat tiny bedroom more efficient. Later on, these skills matured when I studied architecture and started working on things that influence other people's living spaces as well.

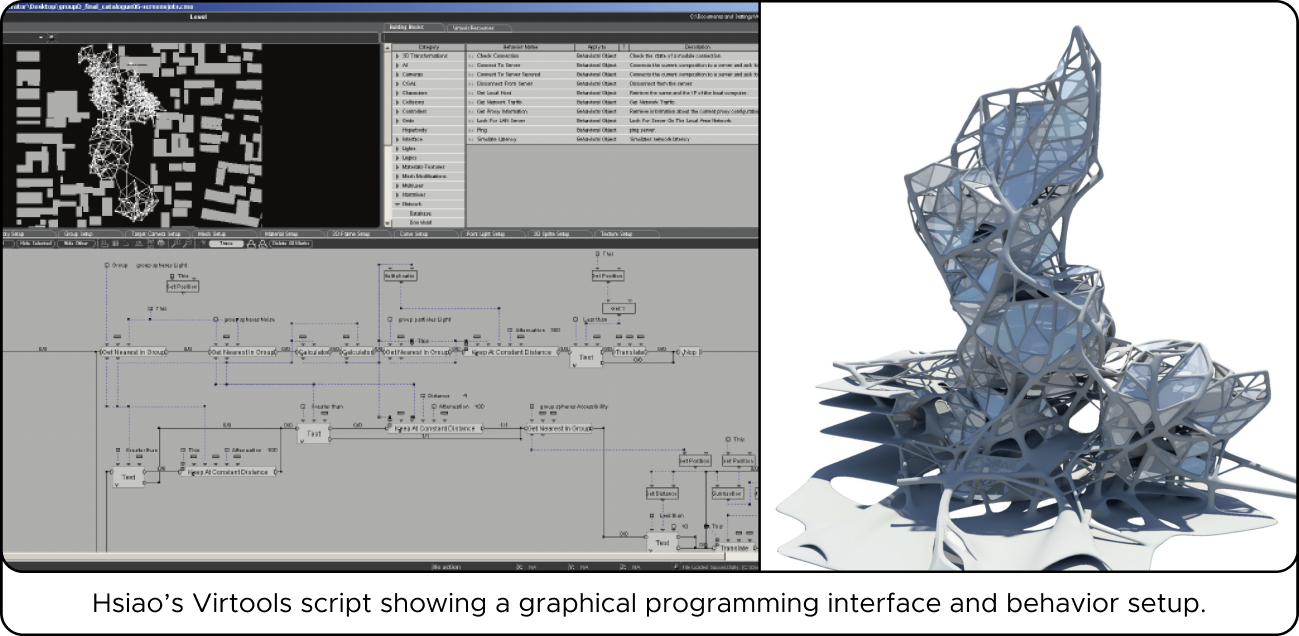

During a lecture from Marcos Novak around 1999, the architectural digital world came to life for me, and I started reading Gilles Deleuze and working with Virtools at the Hyperbody research group. Layering concepts, needs, and ideas together with computational design, for me, became an integrated process from start to finish.

3. How did you discover Grasshopper, and what made you interested in learning it?

In 2009 a good friend of mine recommended it as a then-new upcoming tool to combine design and programming without coding knowledge to create objects and architectural models with my 3D printer. We saw it as the link between the design process and reality. Constant alterations of drawings and prototypes are tedious, and implementing programming in the drawing process makes it much more integrated.

As society gets more and more complex and intertwined, the spatial requirements that are needed can become reality with reactive components that behave controllable in relation to space and function, therefore creating exciting new possibilities and results.

4. How has your background in architecture influenced your approach to design and innovation in the eyewear industry?

In contemporary architecture, geometry design, programming, and the parametric revolution is already up to speed; in eyewear, not so much.

When I started working on my own spectacles in 2011, I slowly understood the level of complexity of design and eyewear was closely related to architecture, and computational design was a perfect way of both learning the trade and not needing to redo all the work continuously.

5. What is Sfered, and how is Grasshopper making it possible?

We are an independent Dutch software company specializing in eyewear customization and virtual try-on (VTO) based in Amsterdam.

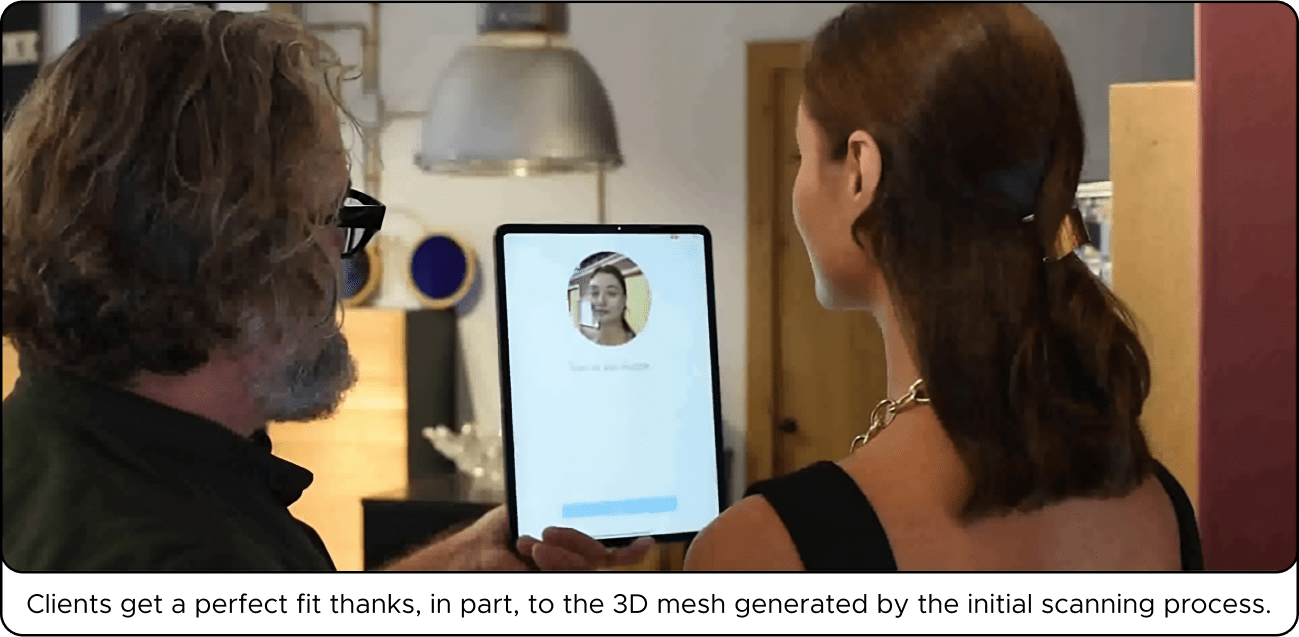

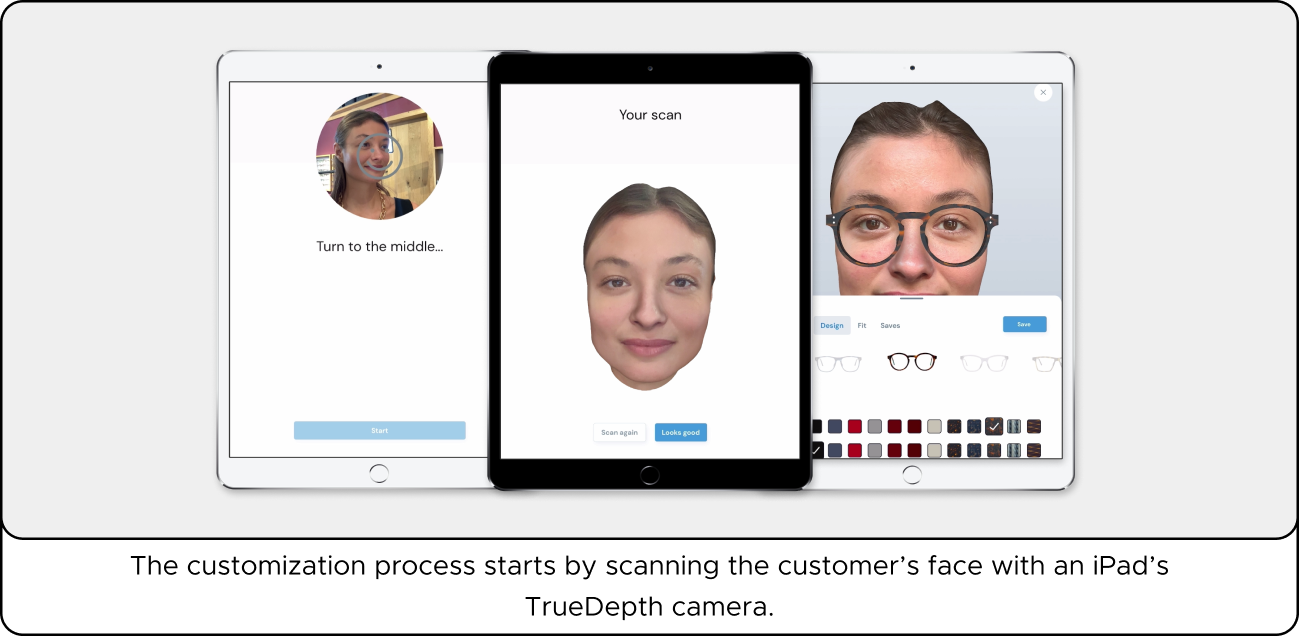

The technology that Sfered built is unique and patented. We were the first to introduce a working customization platform for eyewear in the market. We developed a completely integrated system that positions a frame correctly on a 3D-scanned face and can select a frame based on facial characteristics. Combined with lens prescription, it’s offering a totally customized frame automatically to create a perfect fit.

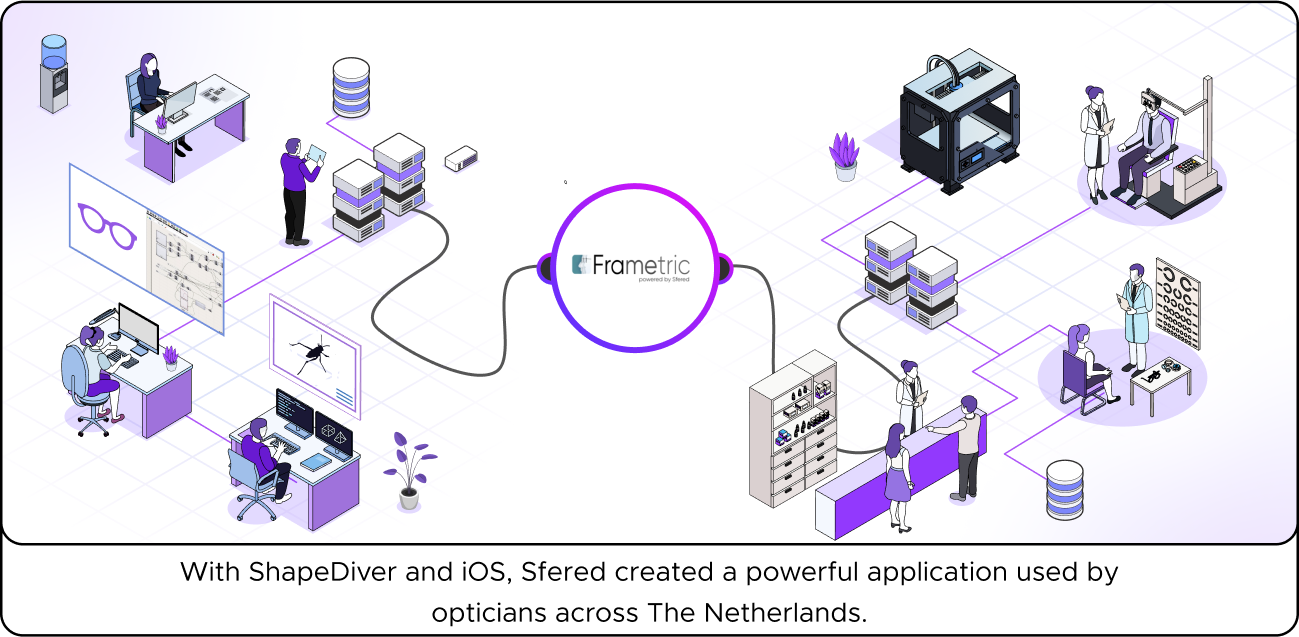

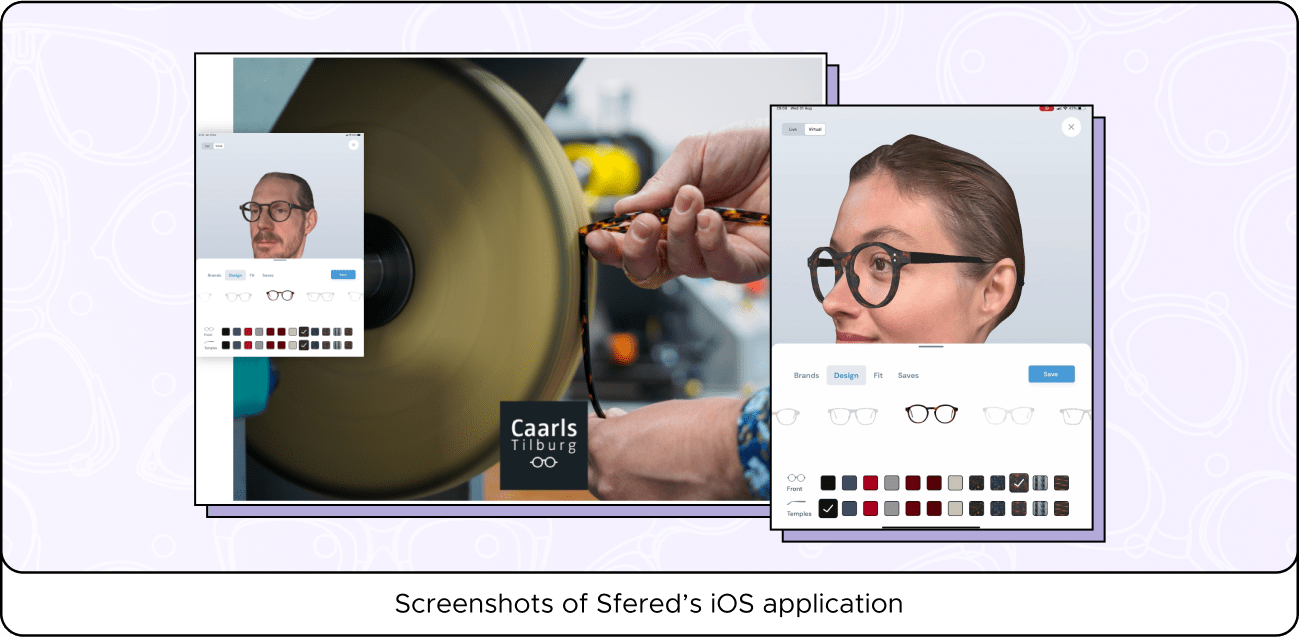

For opticians in the Netherlands, we have the iOS app " Frametric ", the most comprehensive digital solution for fitting eyewear with happy customers.

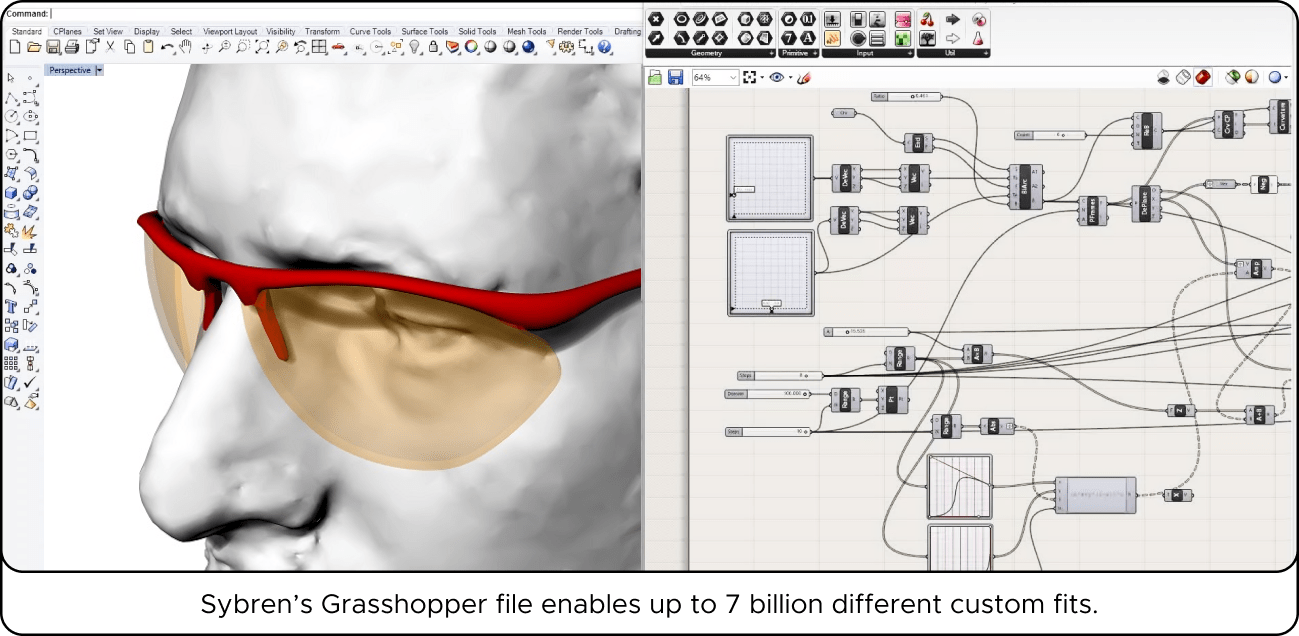

We use Grasshopper in parts of our workflow. Integrating our own code, the design possibilities of Rhino, and bringing the parametric design to a new level with 7 billion custom fits.

6. How has ShapeDiver helped bring your idea to life?

ShapeDiver is an essential part of our backend flow. With their system, our scripts and custom plugins run as quickly as possible, reliably, and safely 24hr a day for customers all over the world. The experienced people at ShapeDiver have been a great help in making this integration work.

7. When did you realize that the concept behind Sfered could be a viable business idea?

The concept itself, custom-made frames, is certainly not new and dates back many centuries, so the business case itself was already there. But it was at a Dutch optical fair in 2015 during the prototype launch that we solved the complex puzzle and could offer a custom frame and 3D-printed on the spot.

8. What were some of the challenges you faced during the development of the Sfered platform, and how did you overcome them?

Getting the complete technology stack working: scanning, user-friendly app, backed systems, and happy clients are difficult beasts to get in line and working.

These challenges can be overcome with the right mindset, team members, and partners like ShapeDiver, who understand the complexity and are intrinsically set up to handle the intricacy that comes with linking different technologies from multiple disciplines.

9. How have opticians responded to using the Sfered tool, and what kind of feedback have you received?

In the beginning, they loved it, and they saw the potential and need in their shop for this technology. Then, it took a long time actually to integrate it on a technical and sales level.

This solution is not for every optician, though. Each shop has its own expertise and methods to reach a good fit. We had several iterations of the whole backend and scan technology before we could match the needs and wishes of the opticians and manufacturers.

10. Can you speak to the importance of user experience in the design and development of the Sfered platform?

Having complex technology is one thing. Getting it to work in a shop environment is something different. It needs to be both simple and advanced, always ready and without any effort transferrable to the manufacturer’s production pipeline. This is something often overlooked. But getting the whole trajectory right every time is a tough job.

11. In your opinion, how is the eyewear industry evolving, and what role do you see custom design playing in its future?

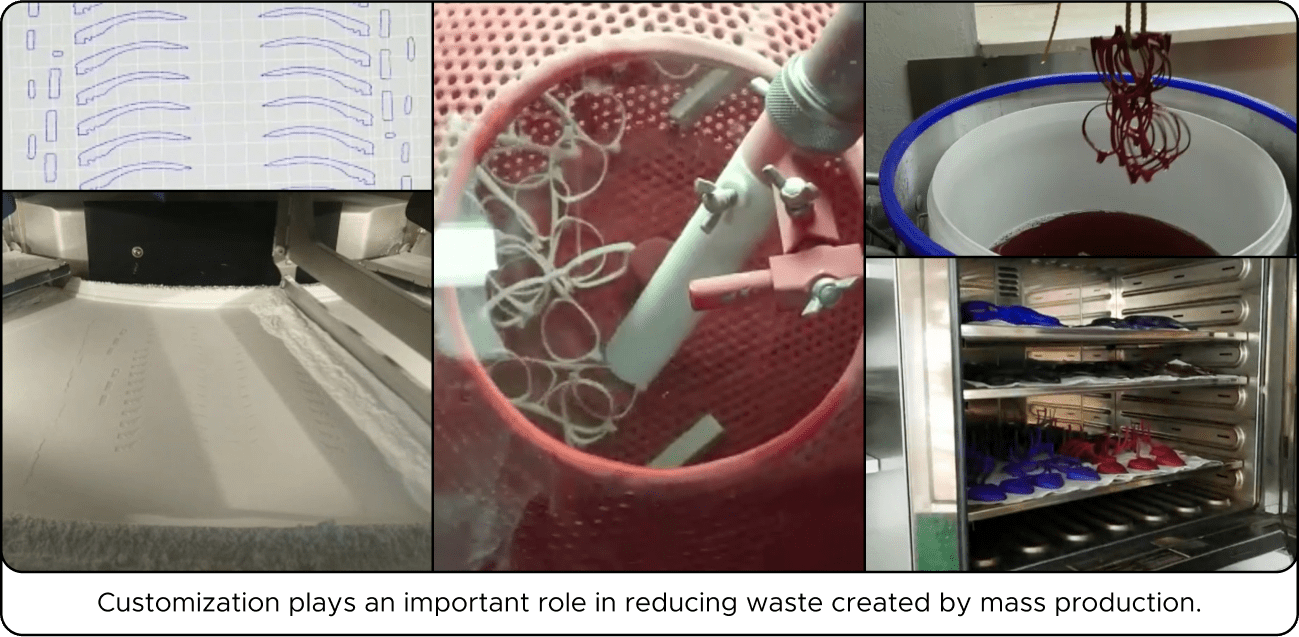

We need to be more careful with our resources, materials (acetate, aluminum, titanium), the attention span of customers, time, and money. They are all limited. Auto customization and made-to-order production are inevitable if we want to keep our planet and our lives nice.

12. How do you envision the future of product design and digital fabrication, and what kind of impact will it have on the eyewear industry?

As far as I can see, the eyewear industry will see more differentiations in design and customization due to the speeding up of the design process and the ease of getting complex geometries under control.

Cheaper eyewear will be less affected by this than high-end brands, where uniqueness and personification are core requirements. High-end collections will be realized more quickly, and brands will be able to create more styles within one season due to the lowering of minimum production quantities.

13. What advice would you give to aspiring entrepreneurs and designers looking to break into the eyewear industry?

Look at the whole trajectory from design to production, from fulfilling the needs and the wearing of the product itself.

14. How do you see technology continuing to shape the future of the eyewear industry, and what kind of developments are you most excited about?

The biggest catch for me is that there will be more complexity and personification available. Hopefully, with this, we can leave the single-face type fit designs and create eyewear that is more fitting and styled for all of humanity.

15. How do you approach balancing the need for customization with the desire for scalability in your business model?

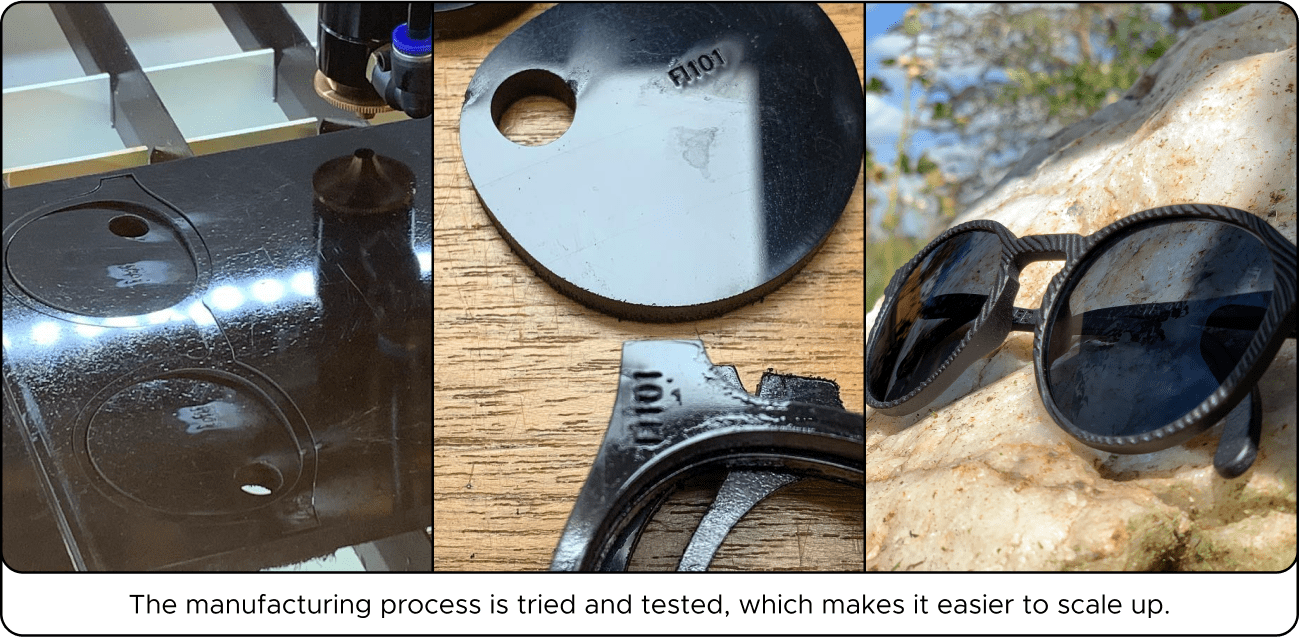

The whole setup is scalable until it hits manufacturing. Each custom frame is made to order. The production process needs to be set up for this with the right production preparation, labeling, monitoring, quality control, and instructions for finishing.

Next to that, the logistics need to be quick and efficient. We take great care in finding manufacturers who are able to do the next level and understand the implications of made-to-order. We now are at the point where we can confidently scale up with regard to preparation for production.

16. What motivated you to offer your technology stack for licensing, and what kind of companies do you see benefiting from it?

I like diversity and more options, and so do many of us. We want to be able to offer end users a perfect fit without compromising on their choice of materials, brands, and looks.

There is so much that goes into a perfect fit; creating eyewear that is comfortable and fitted correctly, getting the production up and running, and setting up the whole flow from scan to result. This takes years and a lot of resources to develop. The good news is we did the hard work and are willing to share this and help others develop their own brand based on our technology.

17. Can you speak to the future of Sfered and what kind of developments we can expect to see in the coming years?

We are working on an even more integrated flow from scan to production. Getting new manufacturing methods and expanding the look and feel of the offer sales and brands. This will help to optimize the user experience and get more functionality based on requests from users.

- Amazing! Thank you very much for your time, Sybren. It's been a pleasure!

Likewise! Thank you for this opportunity as well.

That's it for this new edition of Getting to know... Don't forget to visit

Sfered

and

Frametic

websites to learn more about their iOS application.

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/0d515ee3e3/sfered-shapediver-blog-post.webp)