1. Hello there! Thank you for finding some time for this interview. Please give us a short background on your team.

WOOD-SKIN® was founded in 2013 to help architects and designers bridge the gap between the creative freedom of digital representation and the practical realities of the construction site.

We are architects, designers, and engineers with a shared passion for materials, digital fabrication, and software, which led us to challenge the technical and economic obstacles to creating complex 3D surfaces with conventional cladding materials like wood, felt, cork, plastic, and metal.

We believe that real innovation lies at the intersection of composite materials and digital fabrication, where technology becomes the enabling factor for new building methods and a new design grammar.

2. What is WOOD-SKIN® solving/offering that is so unique?

WOOD-SKIN® created a way to bridge the gap between the idea of a 3D complex surface and its realization. We offer a turnkey solution that presents many advantages compared to traditional systems. Our technology makes the process faster , more scalable, and more affordable.

Furthermore, we consider ourselves as an extension of the architects and designers’ arm. Not only do we offer beautiful products but, with our know-how, we also design, engineer, and install our surfaces.

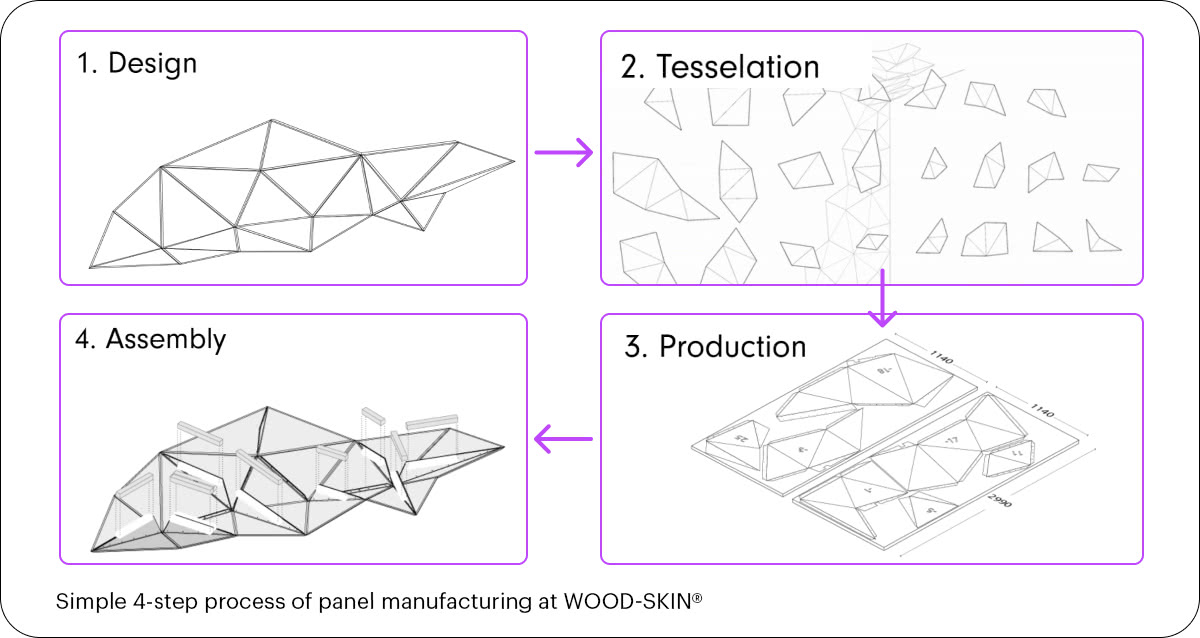

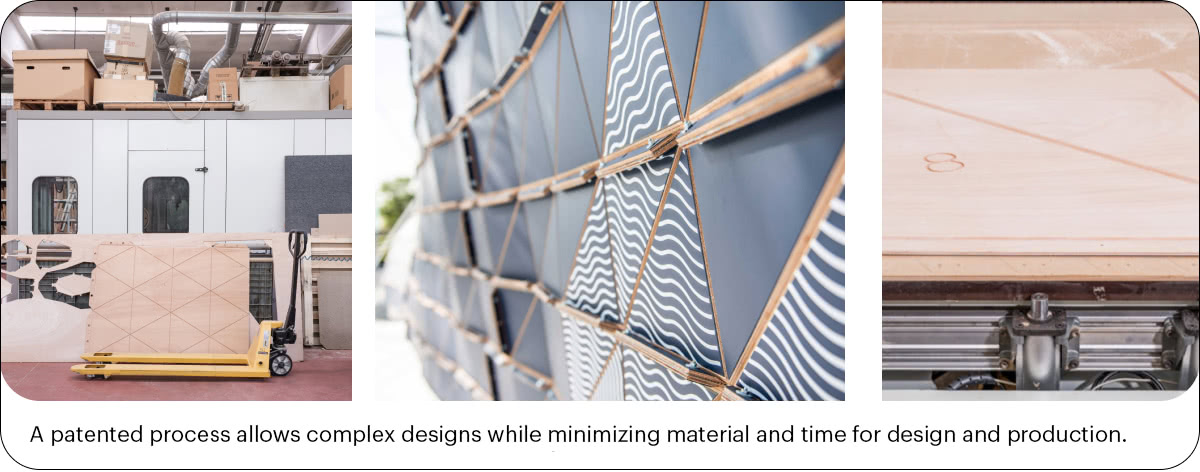

The WOOD-SKIN® process transforms rigid materials into 3D sheets of a “programmable” composite with the potential to be coded and given a specific form through a one-step fabrication process. The patented technology enables the panel to fold along “digital hinges”, much like origami .

From the flat state, the material morphs into the third dimension, where it can assume a range of forms and functions limited only by the imagination of the designer, without losing structural strength.

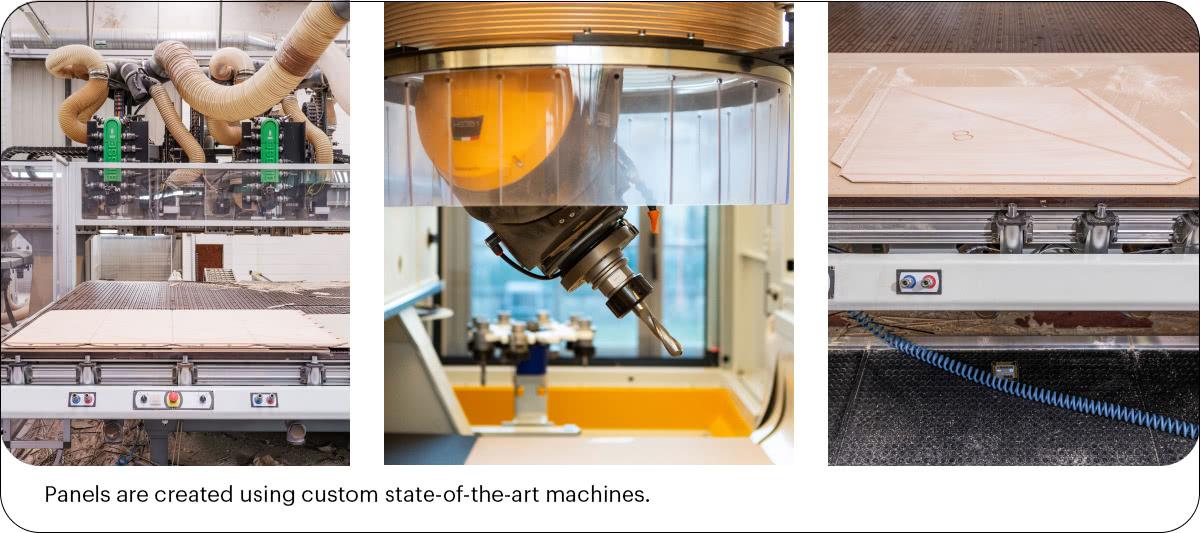

We carefully mix rigid materials such as wood with a variety of high performance textiles, then the sheets are carved by machines with tolerances proper of the aerospace industry.

3. When and how did this idea come to be?

WOOD-SKIN® is the result of years of experiments in the most various fields, from model making to stop motion animation and wood working. At the core, WOOD-SKIN® is a pure obsession for dynamism, materials and innovation. The idea, as often happens, formed during several years of architectural and design practice and ultimately materialized when having to deal with a complex design we did not know how to solve. In other words, we had to solve for ourselves the very issue that is today the core of WOOD-SKIN®’s value proposition, “complexity solved”.

Rather than creating a one-off solution we decided to come up with a system, a technology, later patented, that would have enabled architects and designers from all over the world to transform and thredimesionalise materials traditionally known as flat. After a healthy amount of failures, headaches and obsessive adjustments Wood-Skin was born and launched in 2013.

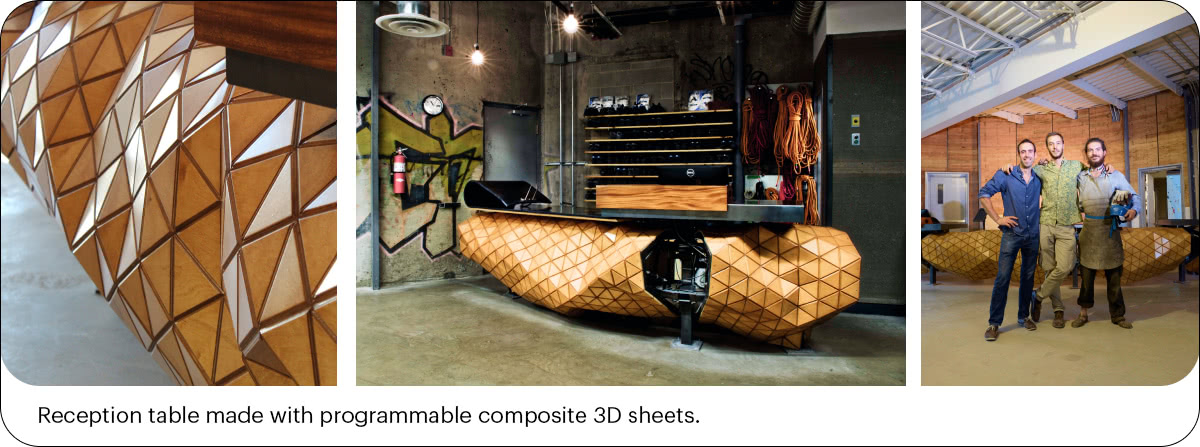

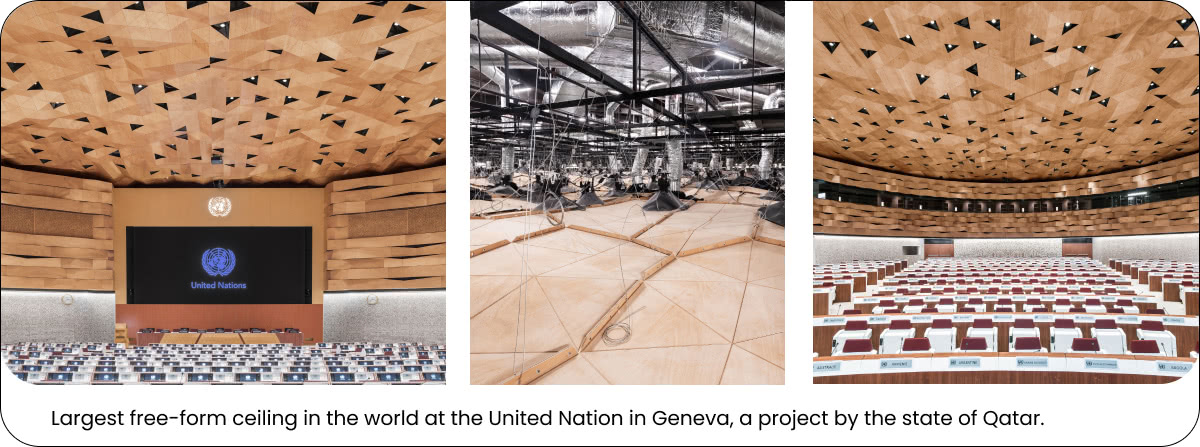

Today the technology has matured enough to go from the first historical counters at the Allez Up gym in Montreal commissioned by the De La Plant family for their gym to the largest free-form ceiling in the world at the United Nation in Geneva, a project commissioned by the state of Qatar.

4. What are the three main products that WOOD-SKIN® offers and what are their main characteristics?

MESH PANELS

The Mesh Panels are inspired by the natural realm, fully tracing existing organic forms and integrating them with the varied world of architecture.

Mesh Panels are the ultimate example of the possibility of the WOOD-SKIN® process, where the 3D surface is locked in shape by a quick-assembly frame that can be then hung to the wall. The meticulous selection of sustainable materials for the new Mesh Panel includes paperstone, print, metallic and non-metallic laminates, as well as Alpi (an ultra-thin and lightweight material), available in a variety of colors and infinite shapes with elegant finishes.

The multi-adaptability of Mesh Panels, guaranteed by their free-form properties, allows them to be composed in several combinations depending on the space they will enrich.

FOLD PANELS

Propelled by the optimization of sustainable materials, the simple design of our Fold Panels establishes a comfortable atmosphere for the user, facilitating any preference through a tailored approach.

Fold Panels are 3D boards with compelling geometries, built inside square or rectangular modules. The Fold Panel concept is uniquely suited to transform a space with the colors and configurations that best fit the project’s overall vision of the architect. The Fold panel system is composed of three different lines: A-gami, O-gami and U-gami.

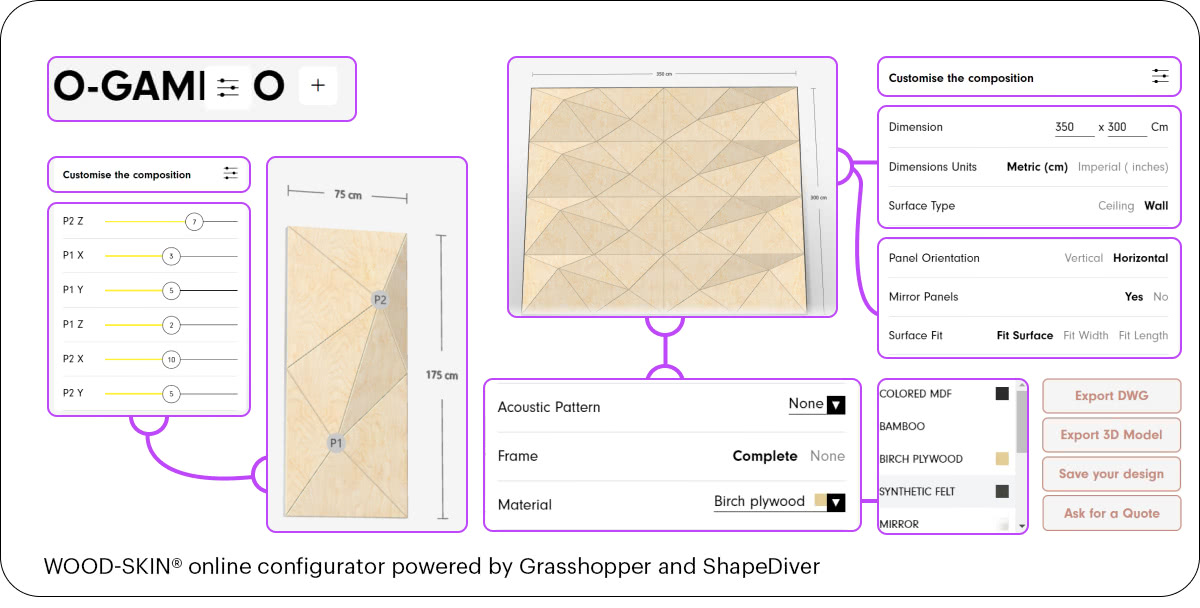

More than ever, these make it possible to create unique three-dimensional coverings with a wide range of material finishes and quick, easy assembly. A robust frame sustains the weight of the panels and facilitates the installation on walls and ceilings. The most important part of the new panels is an online configurator: the user has the possibility to change parameters of the standard panel directly online, changing dimensions, shape, materials, downloading the file and using it inside his project. These online tools are the ultimate expression of the digital nature of our panels.

- - Standard Panel Composer

This tool allows you to combine, juxtapose and orient the panels to create a preview of your composition. For the finish, you can then choose among the laminates, metals and veneers in the collection. Once you’re done you can export a 3D model or a.dwg file to share with colleagues and/or import into your project.

- -Custom Panel Configurator

This more advanced digital tool enables you to intuitively model the form and aesthetic characteristics of the panels at will, thanks to the use of parametric sliders. The configurator allows you to push beyond the logic of the standard product and adapt the Fold Panels to your creative needs, obtaining truly unique results.

TAILOR MADE SERVICE

Tailor Made surfaces are unique bespoke products created for specific projects. The guiding design principle here is the geometry.

Our architectural and design team has years of experience working with top firms on international projects, and there’s nothing that excites us more than the challenge of engineering intricate shapes, designing custom details, and devising solutions to ‘impossible’ problems. For particularly complex projects, our people are on hand to oversee the installation, whether in Italy or abroad.

The WOOD-SKIN® design team is able to discretize any complex geometric input with single or double curvature, and transform it into a series of flat elements easily produced and installed.

Thanks to WOOD-SKIN®’s proprietary design software and programmable manufacturing process, the most expensive and time-consuming aspects of customization are significantly reduced.

5. What are the more challenging aspects of designing and building these products?

The intrinsic nature of what WOOD-SKIN® can be, in terms of designing the elements, opens to many ideas and solutions to complex projects. At the same time, it leaves a "blank canvas" which can be an obstacle, in terms of what can be imagined and how to actually design it.

That's why we focused on creating parametric algorithms for our paneling solutions and making them available online to the final customers, who can integrate bespoke creations into their projects with the click of a button.

This also allows the process to be entirely digital and enriched with embedded information: the customer can receive the precise specifications and data about the element they designed with our tools (downloadable 3D assets, technical sheets, all of this related to the actual configuration created through the online configurator). Our team benefits from having a controlled environment that allows for a "standardized customization", receiving all the necessary information about geometries, dimensions, finishings, application and project location through the same tool the customer is working with.

In terms of building the panels, our statement "complexity solved" best explains how easy the system is, even if it might seem intimidating at a first glance. Thanks to the digital parametric process, we can provide the customer with all necessary information (pieces, fixing order, bill of quantities, etc.) for the product to be easily understood and installed, especially for our Fold and Mesh Panels families.

With the Tailor Made products, it is the same, but with a few more guidelines and solutions customized for each bespoke project we help create. Also, astonishingly even to our experts, when some mismatch happens between the digital and the real site conditions,WOOD-SKIN® can be extremely compliant even where the digital model tells us it should be theoretically impossible. This is thanks to the "digital hinge" programmed into the panels, which can always bend when designed to be left unfixed.

6. How is parametric design and digital fabrication related to these products?

WOOD-SKIN® is designed through the use of bespoke computational tools which enable it to be precisely controlled and allow us to simulate the physical behavior of the skin, parametrizing the geometry and the material, before manufacturing. For this reason, digital fabrication processes are necessary to create a direct link between the digital design and the physical end-product as we are able to inform specifically the CNC processing machine. This ensures the best results in quality and timing for final production.

7. How is ShapeDiver involved?

WOOD-SKIN® is designed to be extremely versatile and adaptable, so that almost any shape can be designed with it. However it needs constraints and parameters that only computational tools can control. ShapeDiver enabled us to offer our clients the possibility of engaging with WOOD-SKIN® computational tools transforming them into simple online configurators. By doing so, it facilitates product communication, eases our clients into self-designing their custom solution, and simplifies the process of transforming digital designs to final products.

8. What are the characteristics of a great online configurator?

WOOD-SKIN® is available in an infinite variety of materials and geometrical patterns. In this respect, it is extremely relevant that a product configurator is easily updatable with new variables in finishings and geometries, that includes good and fast rendering features to represent the real product in every detail, and that it is fast in calculating the parameters changes for a proper user interaction. AR integration is definitely accurate for such a product, because it provides a deeper element of understanding, meaning for the user to see it exactly where it was imagined to be in reality.

9. Is there a relationship between bespoke products and sustainable products?

Sustainability is one of the main attitudes of the WOOD-SKIN® firm and people making part of it in the whole vision. Starting from the digital fabrication process, which aims to optimize resources, time and materials while concurring to create bespoke shapes, making the impossible possible, the whole production process, from concept to completion is inclined towards minimization of energy consumption and waste.

Thanks to the WOOD-SKIN® patented process, we are able to create volumetric shapes, with the most complex designs while minimizing the material quantity and time needed for design and production. Furthermore, our products involve many sustainable materials/finishes such as recycled felt. Also, all the materials and finishes we select are compliant with the highest standards of quality and sustainability available for that specific material on the market.

10. What’s the future of digital fabrication?

Digital fabrication offers a vast range of benefits, from production timing and processes to final cost. Furthermore, it is a great encouragement for architects and designers to explore their creativity and project-customization.

For this reason, we believe that digital fabrication will lead the design and construction industry to a new era of digital craftsmanship, in which standardized solutions will be replaced by mass customization, ultimately leading to great efficiency and virtually zero waits. We believe that truly digitally fabricated products are key to a sustainable future addressing global issues and very customized aesthetics at the same time.

- Well, this was been extremely interesting! Thank you once again for your time. Anything else you'd like to add?

Thank you as well! Just to remind everyone to check out our website and our online configurators.

That’s it for this new edition of

Getting to know...

Don’t forget to follow our friends from WOOD-SKIN® directly at their

LinkedIn

and

Instagram

accounts!

Would you like to get featured in this space? Simply send us an email to contact@shapediver.com and tell us about your project or brand! We’d love to start a conversation.

/f/92524/1200x630/aaa5a63ac3/shapediver-wood-skin.webp)