It is commonly known that AEC is an industry with low productivity and low margins. Yet, it is one of the largest industry sectors per percentage of GDP. This makes many wonders, how come it has not yet grown into a position of strength, such as seen in the Manufacturing Industry a few decades ago? In this two-part article, we’ll discuss some of the problems and opportunities that we see in the AEC Industry and propose a couple of solutions that could help solve some of the main challenges. Welcome to part 1!

AEC and its plenty stakeholders, Source: Autodesk Redshift

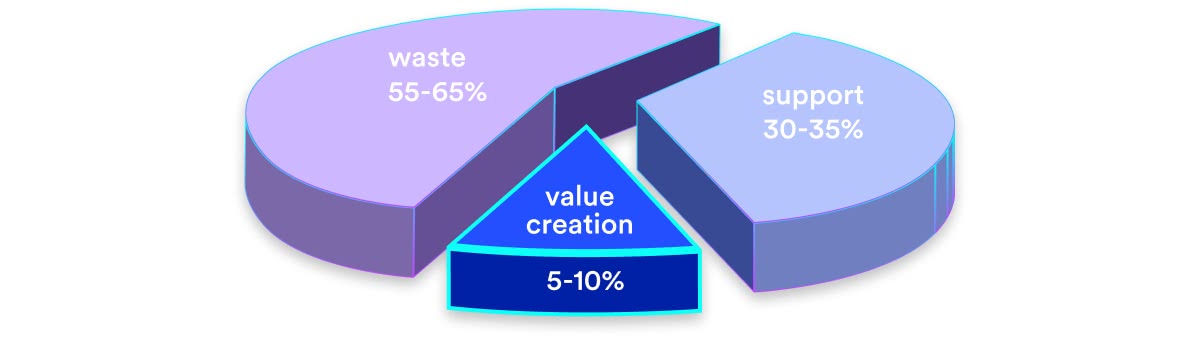

Waste vs Added Value

The assumption that construction deals with low productivity can be measured in several ways. Let’s look at the added value because in fact, today’s output of the sector is in a very severe position:

• 60% of value in construction being wasted, such as in accidents, delays, waiting times, rework, unnecessary handling and damaging of materials, poor payment and tendering systems; the list goes on.

• 30% of value is lost due to support activities, such as procurement, logistics, cost estimating and management.

• Only 5% to 10% is in the form of value creation, or in other words, what the customer actually wants.

What can we do to understand the root cause(s) of these symptoms, how do we get started?

Value creation in construction, Source: Sarhan et. al.

Segmented Stakeholders

The AEC sector is fundamentally fragmented in several ways (often concurrently): within the individual project phases (such as within the design phase), as well across several phases and their stakeholders, and of course across individual projects. As a result, this fragmentation affects the productivity and competitiveness of the industry.

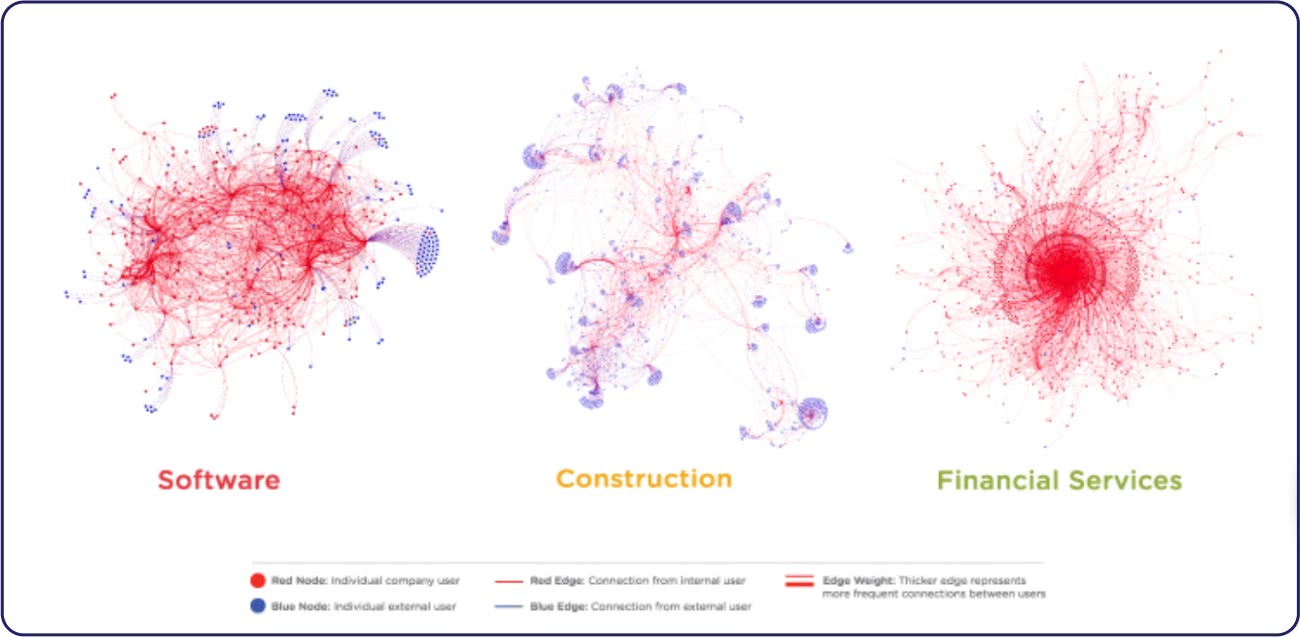

In fact, the value-add in the AEC sector is insufficient and margins are getting increasingly tighter each day. How can we excel moving forward to make this large industry more efficient? Glad you asked! One way is to look at other industries, such as software and financial services. The graphic below illustrates individual company users (red node), individual external users (blue node), and their connections, can you spot the difference?

Network study of different industries, Source: Box

Learning From Non-Project-Based Industries

At the root, the AEC industry and its companies are mainly (capital) project-based, which limits scalability naturally: each project and its stakeholders are unique. Looking to sectors such as software, financial services or (lean) manufacturing, AEC could potentially evolve from being project-based, to processes, platforms and eventually products, providing individual buildings but reusing existing knowledge and tools.

What might appear as obvious to people from other industries, AEC workflows often start “from scratch”, neglecting previously found solutions. We believe that there is no need to begin all over again with each project, so let's start by first looking at how digital workflows in AEC are structured today and how they could be improved in the future, starting today.

Today's Planning & Design Workflow

In today’s AEC projects, digital information is stored by many specialized stakeholders, in different levels of detail, on several machines and accounts, using various software environments and data formats.

In many cases, information is often still being exchanged like a century ago: with drawings and reports printed on paper - breaking the digital chain of information across the projects only to re-digitize the information at a later moment again. As the goal is a flawless and thus lossless workflow, it is important to establish it as early as possible.

In order to apply and automate as much domain knowledge as possible, Application Programming Interfaces (or short, API) can allow for the conceptual hand-shake and check. Perfect, problem solved! Right? Not so fast.

APIs have specific import and export requirements, such as file formats and respective versioning. These details can create frictions on the workflow, potentially slowing it down or stopping it entirely, counteracting their very purpose.

A potential solution to this would require a universal data transfer file format, similar to what our developers at ShapeDiver have been working on together with TT CORE Studio: an open-source and platform-agnostic data format called sdTF . We'll have a more in-depth article diving deeper in what this format can offer to the AEC and different industries.

Breaking Down Barriers

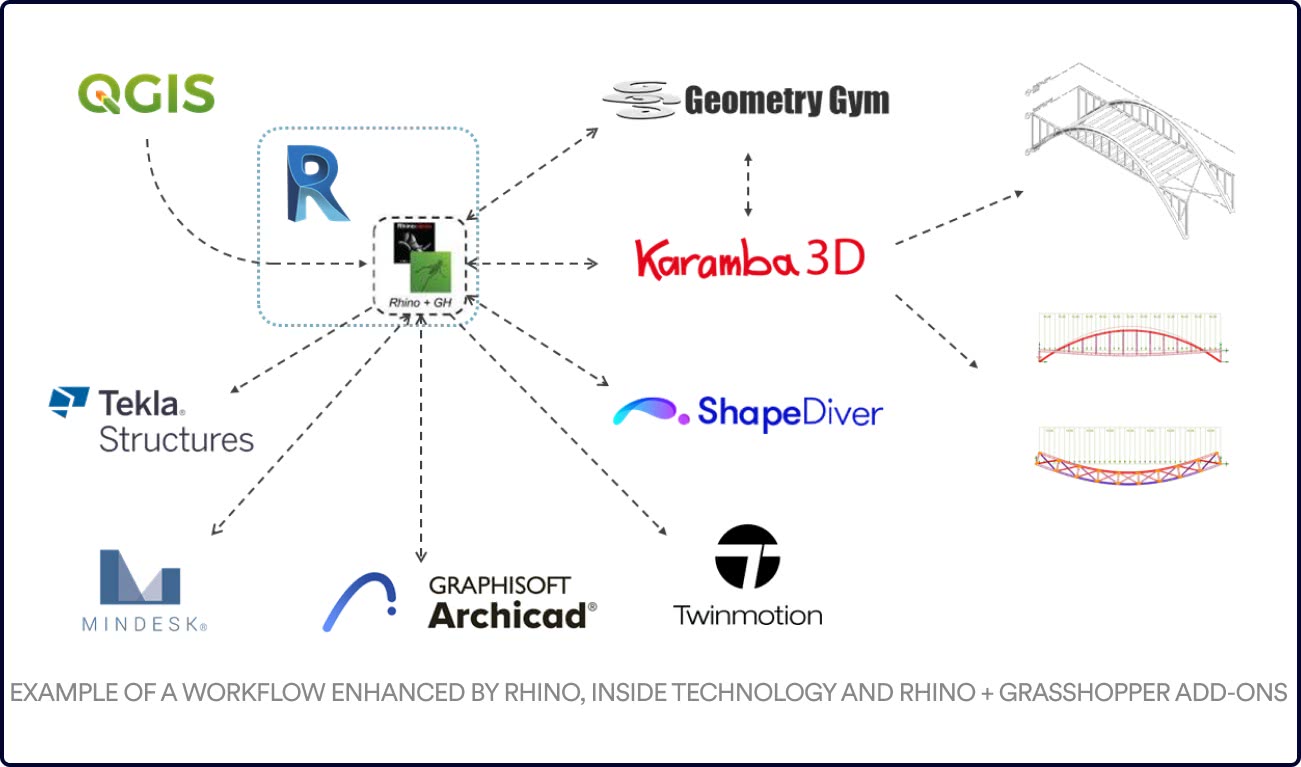

As previously mentioned, CAD and BIM tools are frequently used in AEC. In fact, it is common to use several software environments in a single day. This requires specific technical training and continuous education on each of these platforms and it comes with further drawbacks: accessibility (import, export and storage), version-control and data-loss.

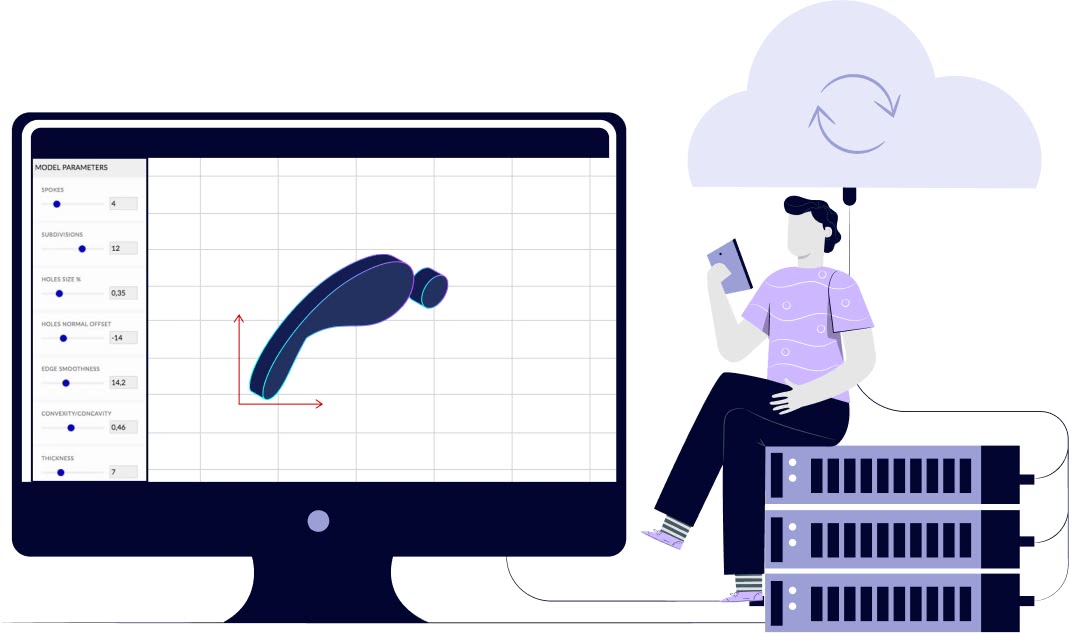

Each platform requires a software license and is commonly limited to a specific user or machine, mostly via a purchase or subscription model. So, what would it actually take to centralize CAD information and be able to import, change and export files natively through a single software environment? The aim of this integrated data workflow is to both ease the collaboration and extend the possibilities within. Hint: cloud-applications.

Workflow example through Rhino3D, Source: Rui de Klerk

Preview Of Part 2

In Part 2 of this article, we will have a look at the current state of cloud applications and discuss the opportunity of boosting remote work productivity, powered by these cloud-based services. This novel way of working allows for better and faster decision making and opens the way for real-time and online, interactive collaboration - right on any device, any browser, and anywhere.

<< Special thanks to Alex Walzer for his collaboration during the writing of this article. Alex investigates the role of entrepreneurship for and in AEC when utilizing nascent production technologies. He is a PhD researcher at the Chair of Innovative and Industrial Construction (Prof. Dr. Hall) at ETH Zürich - and can be reached at walzer.tech and @alexnikw on Twitter . >>

Using Parametric Design On The Cloud!

There are plenty of opportunities for those embracing new, collaborative digital workflows, no matter the size of the company or project. Ideally, it would mean better planning and faster building, overall better quality, and less environmental impact. As another bonus, it also entails more fun and motivation when working, less frustration for you and your team, and, possibly even shorter workdays - a perfect win-win.

/f/92524/1201x631/cea21ebd43/aec-part-1-header.webp)