Introduction

As we've explored in previous articles, there are plenty of areas that are due for disruption inside the AEC industry. While some focus on the construction materials being used, such as Mass Timber, other focus on the actual construction processes, like prefabrication and modularization. This week, we meet the founders behind Toggle, an American firm that is reimagining rebar fabrication with the help of computational design tools like Grasshopper and ShapeDiver.

You'll learn how they got inspired to start this company after witnessing how wind turbines are built, how they got $100K in funding and basically hacked their way until they found 'Product-Market Fit', plus how COVID forced them to have a "work from anywhere" mentality. Finally, they have a word of advice to all new founders on how to navigate the intricate world of startups and funding rounds. We hope you enjoy this unique and inspiring story!

1. Welcome, Daniel and Andreas. Thank you for joining us today! Tell us a bit about Toggle, what it is and what problems are you tackling?

- Hello everyone! Thank you for having us here. I am Daniel Blank, CEO and Co-founder of Toggle Robotics. Ian Cohen and I started this company in 2016 from Brooklyn, NY.

- And I'm Andreas Thoma, I am Toggle's Director of Digital Fabrication and I joined Toggle in 2018.

Toggle is a construction robotics company at its core. We have built a full stack robotics and automation solution for pre-assembling rebar. This, we believe, solves a potent problem of efficiency in the Construction Industry.

The demand for concrete in the construction industry is accelerating. We need infrastructure, we need housing. Cities are becoming larger and more complex than ever before. And meanwhile, there's a challenge to deliver construction quickly, affordably, and at the scale that it's needed. Thus, the solution is to bring in new efficiencies to this particular ingredient that's so critical to construction.

'Rebar Prefabrication' is one of the key focus areas in Toggle’s mission to build world-class robotics and automation solutions for a wide range of physical fabrication and assembly applications in large-scale urban and infrastructure construction.

2. Why did you start Toggle, and what was the motivation?

The motivation to start Toggle is an interesting story that involves wind turbines! The "aha! moment" stems from the mixture of three different ideas that gel perfectly with each other. The first would be to understand the cost overruns in large-scale projects caused by a lot of variable factors that make the project run longer and become more expensive than they're initially anticipated. Why does this have to be the way and can we intervene to make it efficient?

That’s the preliminary thought, but when we look back and realize the tremendous advancement in the consumer products space in our lifetime, from the computer to go from this really heavy thing that is the size of a room to going into a desktop form factor and then to a thing in your pocket and even on your wrist now.

I believe there’s this democratization with consumer products, with things like smartphones and cars and televisions and refrigerators and all of the air conditioners, all of these types of things. But with construction, you know, I think things have always kind of gone in the other direction, like the bigger the project's getting, the more that time goes on, the more the cost overruns.

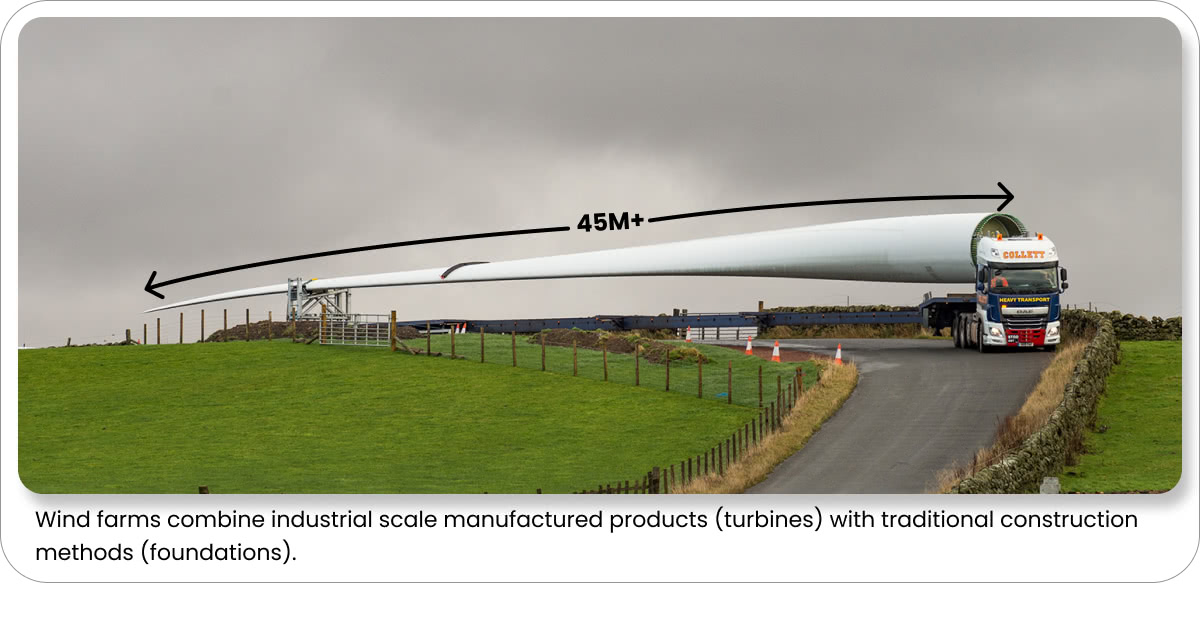

The last piece of the puzzle is my visit to a wind farm close to Vienna, where I saw a wind turbine come together. Grid scale wind turbines are taller than The Statue Of Liberty and are transported onto trucks and prefabricated in factories in controlled environments. The turbine itself came together in a matter of days, however the large concrete foundation, with its reinforcements and other construction activity, slowed things down.

This was sort of the inspiration moment for me to find a faster or better way to do this part of the construction process. And then as we began to explore this, we saw that it applied not only to wind turbines but to the whole construction industry.

3. How/when did you find 'Product-Market Fit'?

It is never an easy journey to find product-market fit. Initially, we had to do a proof of concept where we needed to demonstrate, on some small scale, how we could use a robot to manipulate rebar to form a cage fit for construction.

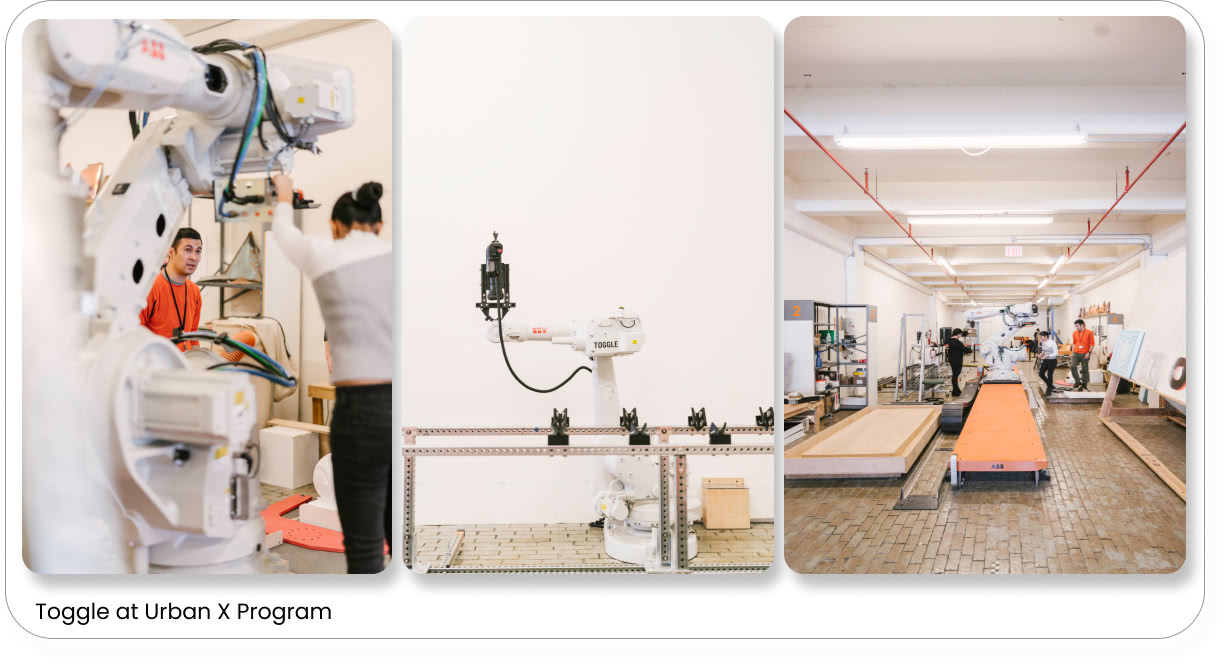

The idea was to get investors to see the potential and get their support. We did get some potential customers but we knew our next step would be to get into an accelerator program where we got some funding. Fortunately, we got accepted into the "Urban-X" accelerator program that's based in Brooklyn, where, as part of our participation, we received funding amounting to $100,000 USD, which was a significant amount considering we were funding the entire company from our pockets.

To go from funding out of pocket to having one hundred thousand dollars to develop, things moved swiftly for us due to the program and it was in this phase that we began working towards product-market fit. The traditional process of making the assembly of rebar is manual. We have people that are picking up pieces of rebar or they're putting them together into these three-dimensional shapes.

At Toggle, we reimagined the process and essentially broke down that process into its component steps and we looked at where we could introduce automation, where could the robots do the lifting rather than the person doing the lifting? Or where could the robot do the positioning rather than the person doing the positioning? Or where could the robots connect to pieces together rather than a person doing that?

After a brief period of experimentation, we found that prefabrication of rebar cages for large infrastructure projects, which have high volume and higher repeatability of shapes, as the perfect 'Product Market-Fit'.

4. For how long did you bootstrap and at what point did you decide that you needed funding ?

We realized very early on that we are both a construction company and a robotics company. We knew it was going to be capital intensive and not something that we could finance out of our own savings for very long because the robots are expensive, the space that we need is expensive and the engineering team is expensive, so it was clear that it’s a high-cost endeavor.

Initially, we bootstrapped and leaned heavily on the academic community. We found the university programs where they were already doing this type of research and this type of exploration. That’s where we all met, me, Andreas Thoma, and Ian.

We had a strategy to just find universities and the public institutions that are already researching robotics and construction, or robotics and architecture, and which are the ones that have great labs that have robots in them.

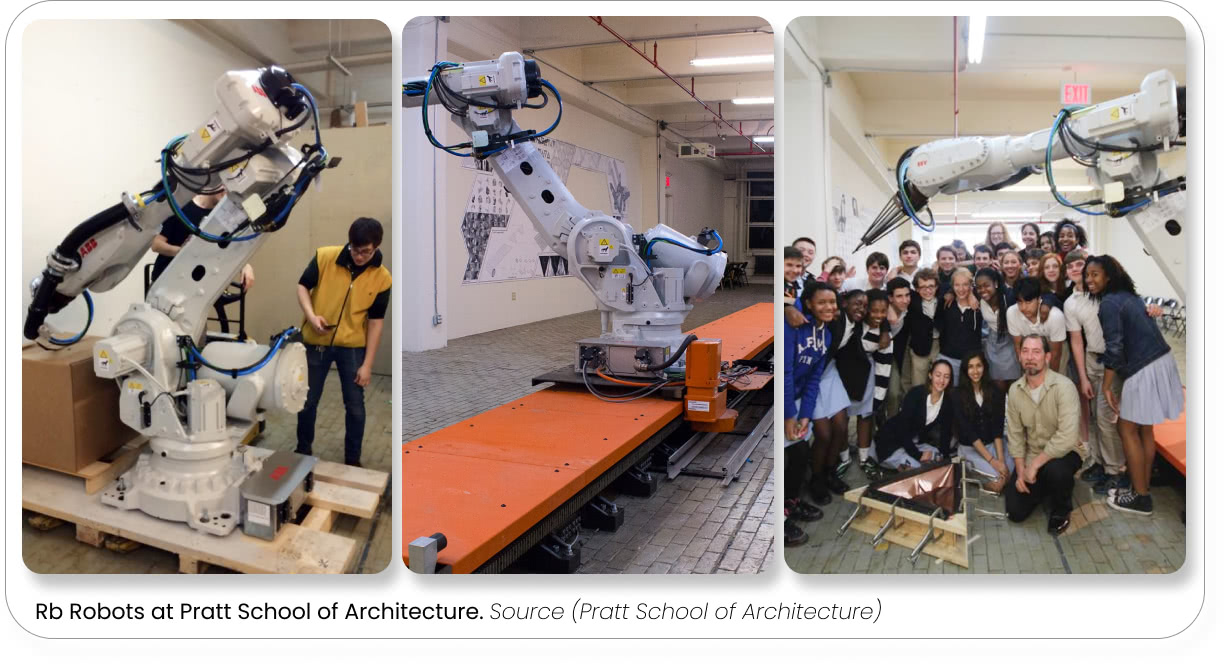

The next step was to gain access to them by either making friends with them or tapping into those resources and getting access to them. And fortunately, we found that we were based in New York City, and there's only one place in New York City where this existed, and it was at the Pratt Institute's Consortium for Research and Robotics, the architecture school in Brooklyn which happened to have a pretty small and pretty modest facility with an ABB IRB 1600 and an ABB IRB 6700 industrial robotic arm on a track.

They were allowing students as well as startups to work with these tools. We experimented for a while there before visiting other schools like MIT, University of Michigan, CalTech and even a lot of trade shows to speak to people from these programs and try to pitch them the idea of Toggle. It wasn't a hard sell as they had already seen architectural and bespoke designs being made by industrial robots using digital fabrication and we pitched them the idea of using robots for creating rebar cages for piers, piles, and columns and that sort. Once we had considerable interest, we knew it was time to go big and get funding.

5. Looking back, what were the initial challenges when starting Toggle?

Everything was a challenge . Right from the capital expenditure to developing capacity to participate in a construction project because it’s one thing to produce like a small sample but to participate in a construction project, you need to be a construction company, which means you need the workforce, you need tools, you need people and you need insurance and many such things which are pretty capital intensive. Building that capacity was the primordial challenge for us.

Then came the technical and engineering challenge of working with rebar, which is a really big one because the main thing that differentiates us from automated manufacturing is that with automated manufacturing, you're making the same thing over and over again, and the parts fit together with a high degree of precision when it comes to tolerances. So like if you visit the BMW factory and you see a robot putting the windshield on a BMW 3 Series, you know it's going to do it the same way every single time, and the windshield is always going to fit into the frame, perfectly.

But with construction, it's the opposite of those things. There are different projects all the time and things generally don’t fit together because rebar is not a precision material. That's really where a lot of our technology comes in, as is in providing all of the flexibility that's needed to skillfully execute that.

6. Can you summarize your journey in finding customers? What was particularly challenging?

Toggle works with two broad different categories of customers. One would be contractors who are on the job site actually building and they need the rebar for the reinforced concrete portions of their structure. And then the other category of customers that Toggle works with are suppliers of building components like the rebar itself or precast. And in both of those cases, those types of companies would otherwise be employing a manual workforce within their factories to assemble rebar.

Thus, Toggle provides these pre-assembled cages to them, or we can provide the service of free assembly to them, sometimes on their material, to alleviate the productivity bottlenecks in the manual assembly that's going on in their factories.

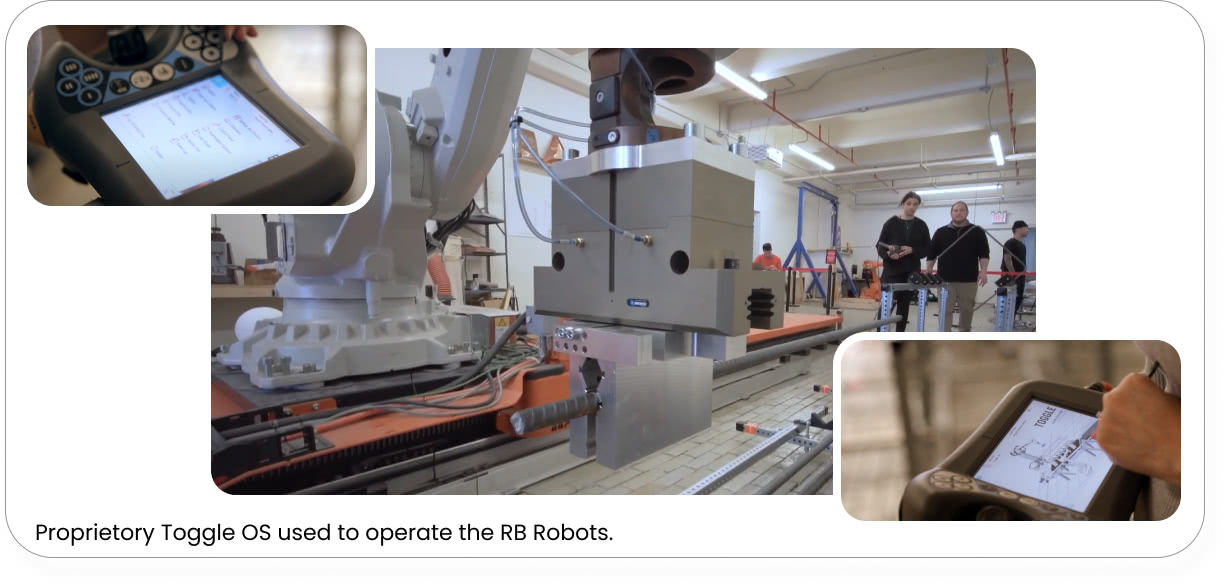

The major challenge was to create a platform to communicate drawing data from either a PDF, a scanned PDF, or general sketch instructions onto a file that the robot can understand and execute. That's where Toggle OS comes into play. It dynamically generates the path planning for the robotic assembly which is essentially the sequence of necessary actions and moves that the robot needs to follow to go from picking up bar number one and putting it in location number one and then picking up bar number two and putting in location number two until you get the finished product.

7. What is digital design? What is digital fabrication and why are you bridging it?

For us at Toggle, we feel the biggest pain point in the Construction Industry is the hand-off point. Typically, the planning team hands over documents/drawings to the contractor to manufacture them. The contractor processes it for construction. However, this handoff is completely opaque to each other. Once done, you don't know what's happening on the other side anymore. It's gone.

We believe that’s what inherently makes the whole construction process also quite opaque. When you're planning a building, you don't know exactly how it's going to be built or what it's going to cost. You just kind of have to guess a little bit, and the more experience you have, the better you can guess. But this transparency from A to Z just doesn't exist yet.

Basically, to enable transparency and enable more trust where it can be guaranteed what something's going to cost and how long it's going to take to build and so on and so forth. We at Toggle feel that we can help with that process and reduce risk in the whole thing. We aim to sit right in between to improve their communication for hand-off and bridge the gap in digital fabrication.

8.How did COVID impact your everyday work inside the company and with clients?

The impact of Covid was quite massive, both physically and digitally. All of a sudden we had to work in a much more distributed way. I think COVID essentially forced us to adopt a distributed team and this kind of "work from anywhere" mentality where you are communicating essentially from everywhere and anywhere.

As a result of that, we have been able to build a team that's brought together some incredible skills and experience that hasn't been anchored to like all being in the same room in the same place. Andreas is in Zurich, I'm in New York. My co-founder Ian is in Pennsylvania. Our production facility is in Pennsylvania, but our R&D facilities are in New York, we have a software developer that's in Seattle and we have a project manager that's in Atlanta. So it's very, very distributed now. But it forced us to come up with the way that we operate as a company to accommodate that.

And so now, we're going to start to build out more of a presence in Zurich with an office there. And we already know how to collaborate across time zones and borders pretty efficiently and it's kind of the nature of our business anyway to have multiple people in multiple locations because we're doing research and development in one place.

We're doing production at another place, our customers are in another place. So it helps with all of that. And I think that broadly speaking in the industry what COVID has done to construction is it's made it even more difficult to have a workforce on the construction site, right?

Due to COVID, new safety, health regulations about the number of people and the spacing, distancing and testing and, all of these things were implemented, which just means it's that much more difficult to have a very large group of people working together in a smaller space and so that incentivizes prefabrication because then it's one less thing you have to worry about doing on on the site. This tactile shift in thinking is the biggest impact Covid has made on the entire construction industry.

9. What role do cloud applications play for you?

As we explored earlier, we are bridging the gap for converting geometry data into a format that the robot understands and can execute. And as we learned earlier, Toggle OS was developed to understand the geometry data and create a sequence strategy for the robots to assemble the rebar into specified cages. But before Toggle OS can send out the data, the drawing needs to be understood and cleaned so that it can be directly plugged into Toggle OS. That’s where our association with ShapeDiver comes into play.

Essentially geometry data can be in any format, either PDF, CAD, or even a sketch. ShapeDiver and Grasshopper help us convert that raw data into an intake format that can then be plugged onto Toggle OS for further fabrication. Since Grasshopper and ShapeDiver can understand and provide the exact geometry data, there is absolutely no room for errors and precision can thus be guaranteed.

10. What would you recommend to new founders in the AEC/ConTech field?

From the business point of view, try to get into an accelerator program that tells you the method, the strategy, the steps that you've got to follow to raise money. They groom you for the investors. There’s less need to reinvent from the ground up because there is already a structure on how to run a business and how to pitch it to investors for funding. Don’t fiddle there. What needs more attention is problem-solving, and that too with focus. So my general advice to new founders is FOCUS.

Try not to solve too many problems, and instead focus on 2-3 problems. Don't try and solve everything. We at Toggle follow on the same lines. We aren't trying to do every type of rebar right now. We are trying a handful of typologies that we've selected that we can fabricate nicely. They are high volume, there's a lot of them, and we've decided to focus completely on that for now. And then as we progress, we will kind of expand our repertoire of what we can do that enables us to progress.

Focus on solving a handful of problems rather than having hundreds of problems at the same time. The chances to succeed are much higher if we are solving a handful of problems step by step and achieve solutions and focus our resources entirely on that. Toggle is built on enhancing efficiency and we feel that is the way forward for us.

- Well, thank you very much for your time, Dan and Andreas. This has been an excellent overview!

Thank you as well for having us!

That’s it for this new edition of Getting to know... Don’t forget to follow our friends from Toggle directly at their LinkedIn and Instagram accounts!

Would you like to get featured in this space? Simply send us an email to contact@shapediver.com and tell us about your project or brand! We’d love to start a conversation.

/f/92524/1200x630/55c2ea1ada/toggle-shapediver.webp)