In this interview, you'll get to know the team behind

Cake Houses. This startup was founded by three Czech architects that had the goal of building an affordable family house that could also meet the criteria of quality in the 21st century.

Their inspiration is deeply rooted in the classical Czech village buildings and their proportions and layout. This helps Cake Houses to fit in various sites and contexts appropriately, while also combining good design and repetitive construction techniques.

By using parametric design and CNC machines, they effectively reduced design and construction time on-site where the finalized parts are assembled on the spot. This way, they are trying to counter some of the biggest problems of the construction industry, like the complexity of working with multiple vendors and contractors.

1. Hello there! Please give us a brief background on your team, profession, and hobbies.

We are three young architects based in Prague, Czech republic. We first met at the Technical University of Liberec and later started working as a team. Our interests vary, from playing chess or volleyball to amateur hairdressing, surfing, making music, parenting, etc. There is a whole lot of it.

2. What is “Cake Houses,” and why did you come up with this concept?

Cake Houses is our answer to a simple question: is it possible to build an affordable family house that meets the criteria of quality architecture in the 21st-century? Our motivation comes from the reality of Czech suburban areas and housing estates that emerged in them. Projects that might fulfill the idea of cheap but whose architectural quality is at least questionable.

The central concept is to combine good design and the advantages of a typical house typology, such as repetitive construction, both backed by computer technology. We believe this combination can bring quality architecture to more people and make it more affordable.

3. What are the design inspirations behind this?

We got inspired for the design of the house primarily by the classical Czech village buildings, reinterpreted and adjusted to fulfill the needs of 21st-century users. A similar proportion, roof, and layout are the attributes easily found in historical buildings all around our region so that the house can fit in various contexts and sites. It is universal and timeless.

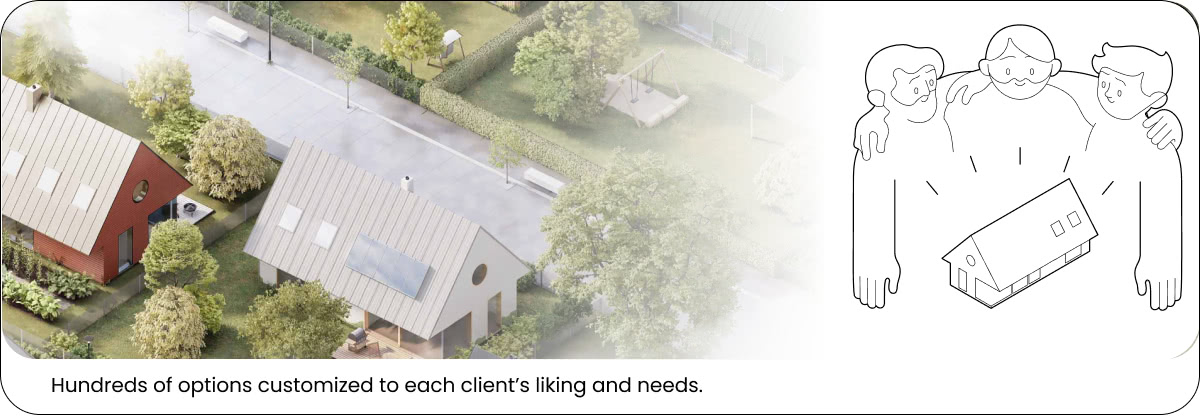

The inspiration behind the concept was based on different types of industries, such as automobile or furniture production. Industries that adopt standardization as a way of reaching affordability. We also implemented the aspect of personal customization, which is thanks to computer programming, a fast-growing worldwide phenomenon. Our goal is to connect all of the above.

4. What’s the main problem you’re trying to solve with Cake Houses?

We know that architecture can be expensive, partially because every building is basically a prototype developed from scratch. Aside from the price, it is often a complicated, stressful, and time-consuming process not everybody wants to be part of. That's why many people decide to build cheaper, faster, albeit poor-quality houses, as seen in extensive catalogs of predesigned projects.

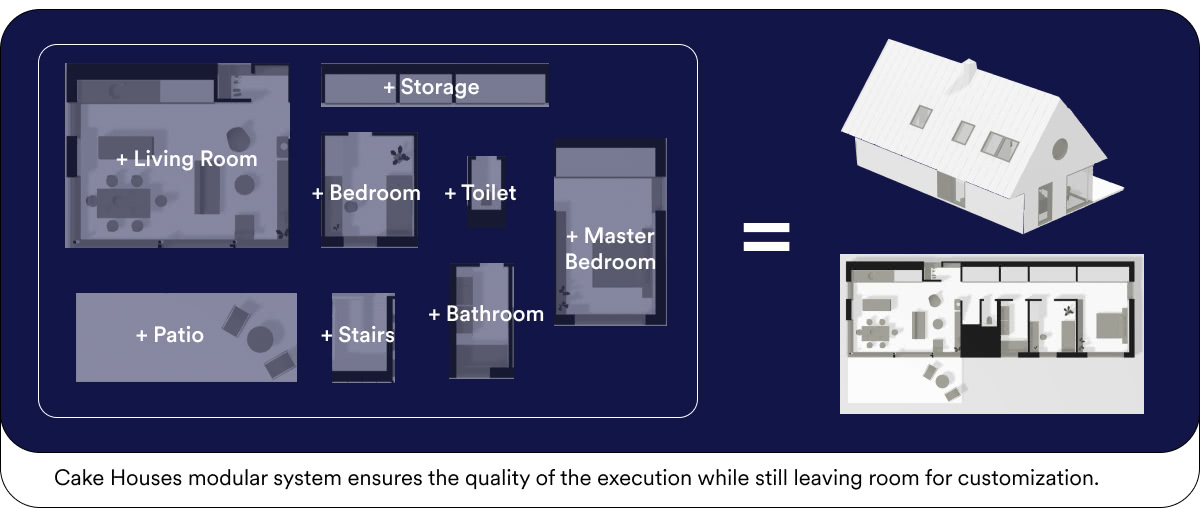

Our goal is to change this. We believe there is a massive gap between working with architects and choosing from the catalog. That is why we developed a variable type house of good architectural quality that implements the ideas of repetition and modular framework to lower the price.

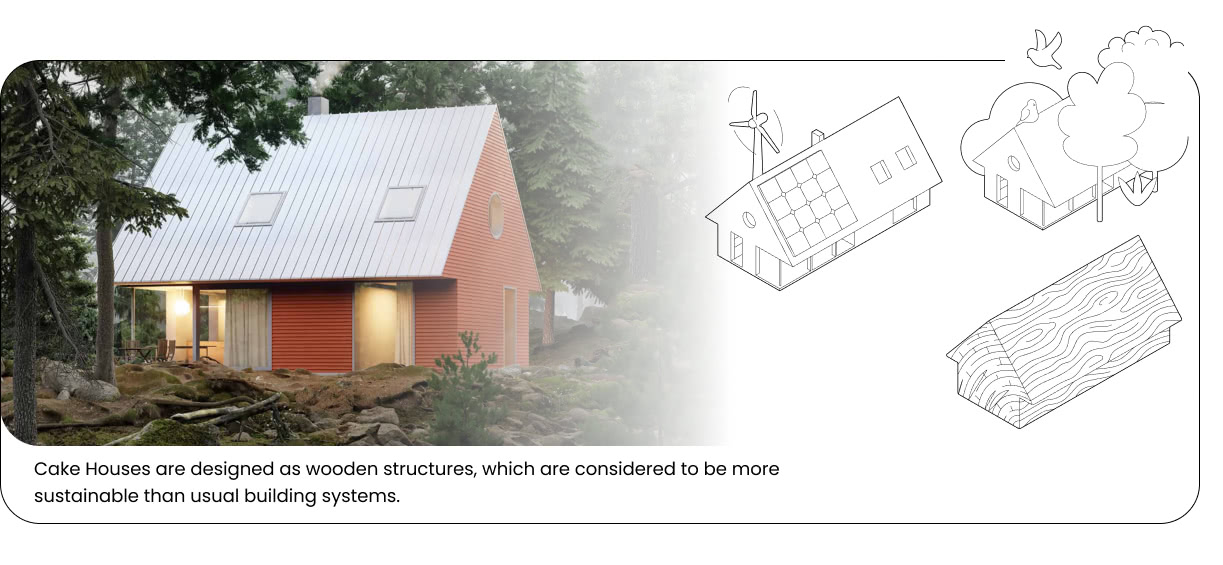

5. How is sustainability embedded into this project?

We are aware of the material and energy consumption of the building industry. That is why we designed Cake Houses as wooden structures, which are widely considered to be more sustainable than usual building systems. Wood is renewable and practical to construct from, so we see no point in making typical family houses any different. The modularity and repetition help us avoid unnecessary waste of energy and material during construction.

The house adopts an intelligent energy management system and uses a thermal pump, which can be combined with other alternative energy sources. The preferred orientation and volume of the house also help to reach efficient thermal profits.

6. What type of manufacturing techniques are involved during this process?

All components are supposed to be made on a production line using modern CNC machines. Finalized parts are then transferred to the particular site and assembled on-site.

We use manufacturing techniques that are widely considered standard nowadays and have yet to find an alternative that would save money for our clients or us. Perhaps we will be able to experiment with advanced technologies such as robotics or large-scale 3D printing in the future. Still, for now, it is more practical for us to stick to the standard methods the industry provides.

7. What were the main challenges throughout the development of this project?

The biggest challenge for us was (and still is to date) the overall complexity of it. Practically everything that exceeds the “good old-fashioned designing.” Throughout the whole process, we were forced to leave our safe space to become programmers, salespeople, marketing experts, illustrators, etc.

Aside from that, another problematic matter is the complexity of the building industry in general. Let’s say that creating a variable house is a bit more comprehensive than creating a variable table, mainly because of the number of contractors, crafts, details, and legislative procedures involved. We chose a pretty tricky problem to solve!

8. How did modular design influence this whole concept?

We use modules as the basic units to construct our Cake Houses. Thinking in modules provides us with the variability of the internal layout so that houses can be configured according to our client’s requirements. In this case, modular systems support the idea of repetitiveness. The same construction system is used over and over again, ensuring the quality of execution and reducing the material residue as well as the cost.

Unlike previously, where modularity meant that many parts were produced and afterward connected, we instead use more recent programming techniques that allow us to create virtual modules and connect them beforehand inside a fictional environment.

9. What’s the right balance between predefined options and fully parametric?

That pretty much depends on the overall characteristics of the project itself. In our case, the use of fully parametric designs would simply not be worth it. Instead of experimental construction systems, we focus on constructing in conventional ways to make our designs more accessible and affordable. Some pre-definitions come from the materials and systemic parts we use - materials that already exist and are very much standardized in production shape and size.

Although some fully parametric projects interest us, their implementation would require a different type of manufacturing than we currently use.

10. How are Parametric Design and Grasshopper involved in this project?

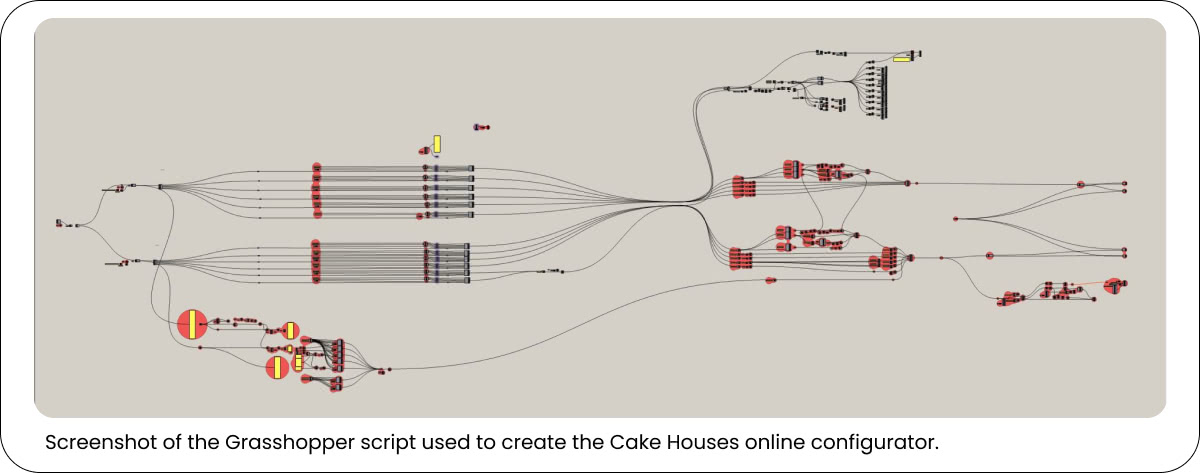

Since programming, generally speaking, is more and more involved in many human activity fields, it is no surprise that architecture is not an exception. We, as architects, feel the need to face these changes and not act like they don’t happen. For us at Cake Houses, this evolution is even more important to follow, and Grasshopper is a great tool to help us.

We don’t use Grasshopper strictly for the usual Parametric Design; instead, we connect different predefined parts via our algorithms. You can liken the whole system to a toy construction kit, such as Lego.

Grasshopper helps us connect blocks and, therefore, automatize designing and drawing plans. When it comes to the combination of computer science and architecture, we believe that there are endless possibilities to explore.

11. How is ShapeDiver helping you?

Thanks to ShapeDiver, our customers can easily view and examine our designs in 3D via their computer or mobile devices. The connection to Grasshopper works exceptionally well! We can quickly transfer our virtual models from our computers to the internet. Our clients can explore the possibilities of Cake Houses on their own. Or show and discuss the designs with their friends at any time, anywhere.

When clients visit our office, the project they designed via the virtual configurator can be quickly transferred back to Grasshopper and Rhino. This enables us to make different adjustments, give a walk through the house in virtual reality, and more. It is easy, fast, practical, and fun.

12. What’s the future of affordable housing?

That’s a big question, especially nowadays. In recent years, we have witnessed significant growth in the general size of floor area per person. Although this will probably continue in developing countries, it is most likely to halt in the Euro-American context, where the construction costs have already gotten far too high. In our opinion, housing could and should become more practical and less expensive.

A good example of this may be a recently expanding phenomenon of tiny houses. Given that contemporary housing production is strictly connected to resource and land consumption, shifting to a more sustainable living and economy could be a game-changer. Housing projects should and hopefully will become more responsible.

However, we think our habits and needs do not change that often in terms of general typology. Therefore, we don’t expect any massive shift towards some kind of highly alternative housing projects anytime soon.

13. What’s the future for Cake Houses?

Another big question! We find ourselves at the beginning of our journey and will have to wait to see where the road leads us. Nonetheless, we see massive potential in how Cake Houses work as a system.

For instance, in the context of the current construction industry, you can see how repetition and overall sameness keep the prices low. We can imagine situations where you use the same repetitive techniques in different ways to keep the structures construction-wise similar, but to develop houses that are different in their shapes and materiality. This could be a valuable tool to reach more diversity and less tediousness.

The idea of designing the principles according to which the house is designed, rather than one final plan, is what interests us. We would like to explore this subject further and further. But only time will tell.

- Thank you very much for your time today. This has been very inspiring!

Thank you as well for the opportunity. We hope to share even more exciting news with you in the future.

That’s it for this new edition of Getting to know... Don’t forget to visit their website and to follow them on their Instagram account!

Would you like to get featured in this space? Simply send us an email to contact@shapediver.com and tell us about your project or brand! We’d love to start a conversation.

/f/92524/1200x630/ae247e9bbc/cake-houses-shapediver.webp)