Since the Industrial Age, businesses have been characterized by centralizing their manufacturing capabilities, costing them crucial time, limiting their reach, and most importantly increasing their product’s carbon footprint.

To change this linear approach to Manufacturing, according to the HP Digital Manufacturing Report , out of 2000 companies that took part in the survey, a whopping 52% of companies are looking into Distributed Manufacturing, a technique that is seamlessly transforming how products are designed, produced, and shipped to customers.

In this article, we’ll explore what Distributed Manufacturing is, its benefits and how any company can adopt it for its own business strategy. Let’s get started!

What is Distributed Manufacturing?

Simply put, Distributed Manufacturing is the production of goods at the point or near to the point of consumption by end users. It has furthermore come into the limelight due to multiple reasons, but mainly because it is reinventing the manufacturing industry from its linear, monolithic and closed approach to a more transparent, customizable, and small-business friendly approach.

Additionally, the rising energy prices have directly influenced the increase in shipping costs , all while adding exponential stress and increasing the burden on the environment.

Finally, COVID-19 induced supply outages worldwide , which have caused manufacturers to relook and move their production processes nearer to the consumers for business continuity and safeguarding themselves from any disruptions caused due to trade and tariff wars.

These reasons have led to the growing adoption of distributed manufacturing or “Localised Manufacturing” as a business strategy and therefore it is not surprising that many companies are looking into this method for 2021 and beyond.

The Rise of Distributed Manufacturing

Distributed Manufacturing has been around for some decades now. However, due to a wide number of reasons, businesses have been motivated to rethink their production processes.

Over the years, Distributed Manufacturing has come up to be a proven business strategy for businesses with products that have a high need for personalization.

On the one hand, it describes the merging of internet platforms with more adaptive, flexible, and digital manufacturing technologies. It embodies a vision of the future in which everyday goods can be personalized and manufactured on demand within short distances of customers or end-users.

Design Locally, Service Globally - Benefits of Distributed Manufacturing for Businesses

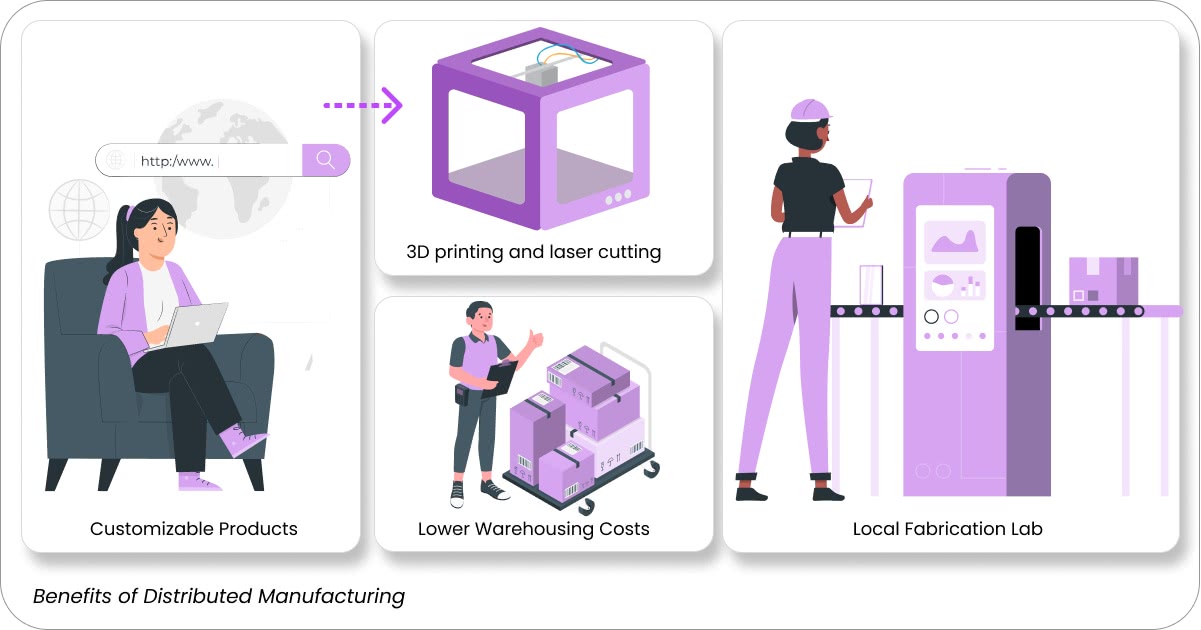

The benefits of Distributed Manufacturing are manifold for customers:

- The final design and characteristics of a product can be decided at the very end when the customer is about to make the purchase. This ensures that the client is more satisfied with the final outcome and less likely to send it back.

- Automated production methods, such as 3D printing and laser cutting, reduce human error and ensure that only the right amounts of material are used to manufacture any given custom product, thus eliminating waste and the need for keeping an inventory.

- Manufacturing happens when and where it is needed, most of the time very close to the customer instead of in far away, centralized locations. This flexible on-demand manufacturing avoids any pre-financing of products, minimum manufacturing quantities, or over-manufacturing, as such enabling an efficient and low-risk approach.

- Warehousing costs get reduced, or in many cases eliminated entirely, as well as logistics and shipping expenditures, which reduces a product’s carbon footprint. A product doesn’t need to travel from far away places, but rather from a local fablab or in other cases the customer can manufacture the product herself at her own home via 3D printing.

Adoption of Distributed Manufacturing For Your Business

We have now briefly understood how this approach works and how it can benefit a business. However, is it right for your business and if so, how can you adopt it successfully?

To successfully adopt Distributed Manufacturing for your business, digitization of manufacturing at multiple levels needs to be embraced. Digitization will not only accelerate the growth but also help in scaling up your business offerings to a larger, global, higher-paying clientele.

Our research highlights 4 major facets of your business that needs digitization for better adoption of Distributed Manufacturing, they are as follows:

-

Production Strategy:

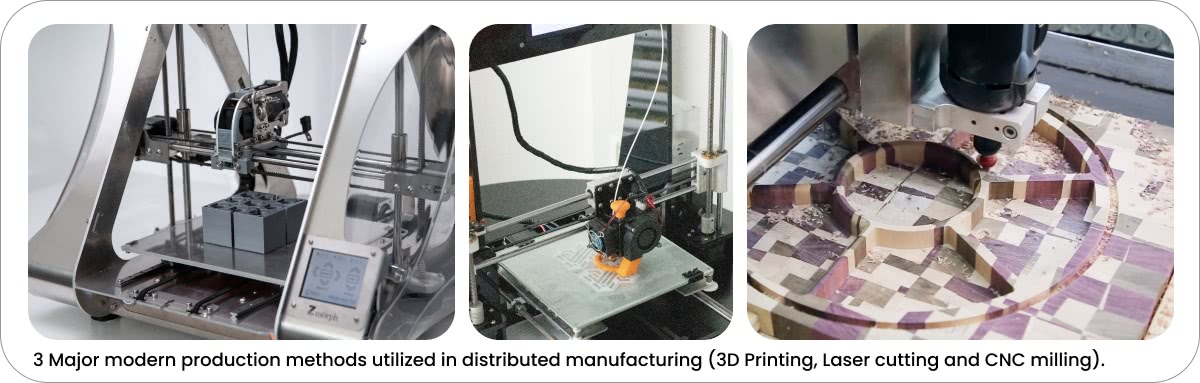

Rethink your production strategy in order to embrace advanced production methods such as 3D printing and CNC methods.

-

Production Automation:

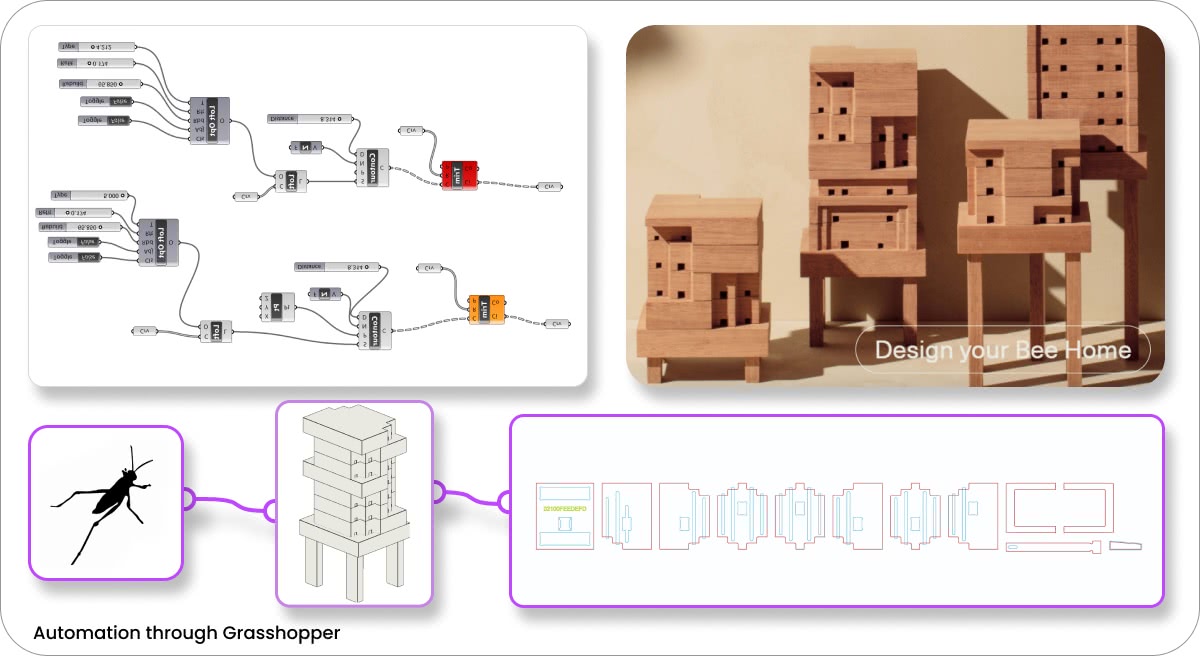

Automate the generation of production files, via software like Grasshopper. This also enables having products with a high number of parameters.

-

Remote Collaboration:

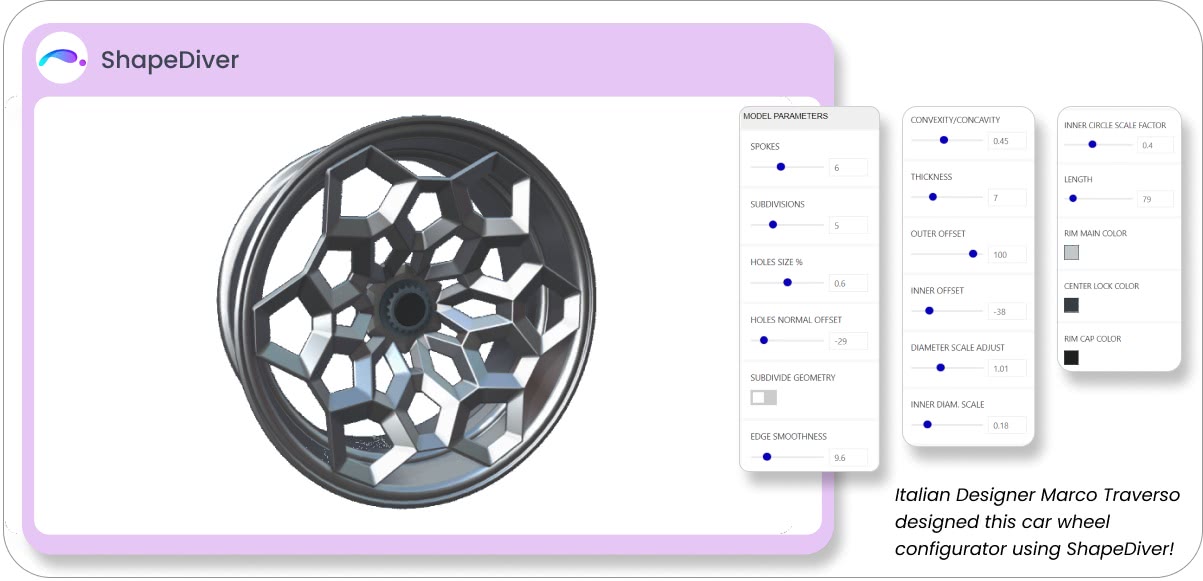

Allow users to customize a product from anywhere and any device, for example with cloud platforms that host Grasshopper files like ShapeDiver.

- Digital Storefront: offer a website that allows clients to pay and customize their products with a custom and intuitive UI and the latest payment options.

1. Production Strategy

The traditional way of manufacturing parts and shipping to various destinations is almost unsustainable in the present world, especially for smaller companies. There is a pressing need to rethink the production strategy of your business to stay competitive and provide value to your customers. Therefore it is inevitable as we have to embrace advanced production methods such as 3D printing and CNC methods that have a transformative impact on the ways we make our products. Integrating these advanced production methods not only makes financial sense but also safeguards our business to supply chain outages. Here’s how the production strategies in the Construction industry are undergoing a digital transformation.

2. Production Automation

One of the most crucial and tedious steps is to create a detailed and precise fabrication file for your product. Add in customizable parameters in the mix, where clients custom configure their purchases/products, your business is now burdened with extra costs, delay in the creation of production files, and increase in production times.

However, via Computational Design and software like

Grasshopper

, any business can automate the process of file creation while also enabling to launch products with a high number of parameters that customers can choose from. This is not just limited to

getting a sketch into a functioning prototype

but can be extended to complex business processes such as Jewellery design and Furniture design.

3. Remote Collaboration

After resolving how customizable products can be manufactured and production files can be automated, the next step is to host these files on the cloud and allow users to customize a product from anywhere and any device.

To empower users for this kind of experience, a robust cloud application is of prime importance. One that hosts Grasshopper files as well as helps users to customize their favorite products with ease and convenience.

ShapeDiver is a cloud application that not only hosts your Grasshopper files but also integrates seamlessly into your existing design framework, helping you have an unlimited number of customizable parameters for your products.

4. Digital Storefront

Once we have a seamless integration of all things that happen during and after purchasing a product, it's now time to have a storefront that not only lets users customize products but also lets users seamlessly pay and order their products directly.

Online 3D configurators provide great value to both your business and your customers when seamlessly integrated with your digital store. This Digital storefront is nothing but your own website that has a flawless integration of ShapeDiver and payment gateways. Here are 6 different use cases for integrating 3D configurators onto your website.

How does everything look when put together? A great example is Nomade Editions from Germany. They offer their clients the ability to order a fully fabricated table, shipped to their home or a more eco-friendly alternative of just purchasing the production file. This allows their clients to use a local FabLab instead of having the product shipped directly to their address. Here's an interview with Nomade's owner, Paolo de Jesus.

Summing Up

As we learned in this article, Distributed Manufacturing is a process that brings many benefits not only at the business level, but also at the environmental one. For this reason, we believe that every business should incorporate this methodology into their supply chain at least to some degree, be it in production strategy, production automation, remote collaboration, and even on your own website.

However, it is also far more important to not just adopt it but also have the right framework to ensure its success. ShapeDiver is a great platform that helps not only to build but also allows seamless integration of cloud applications with the power of Grasshopper and parametric design.

Are you thinking about integrating Additive Manufacturing or 3D experiences into your eCommerce startup and would like guidance on the process? fill out our contact form and our team will be happy to listen to your needs and guide you through the entire process.

For everything else parametric, check out our blog for updates or subscribe to our newsletter and follow us on

Instagram

and

Twitter

.

/f/92524/1200x688/5484656fe7/distributed-manufacturing.webp)