Eric Guenther is the Co-Founder and Principal of Interstice. He brings a unique combination of structural engineering expertise and architectural insights to the AEC industry. He has a deep background in both design principles and computational methodologies, which makes him a leader in industry innovation. His work at Interstice and his role as Digital Practice Manager at Forefront Structural Engineers reflect his strong focus on bridging gaps in the industry and pushing the boundaries of traditional engineering practices.

In this exclusive interview, Eric talks about the origin of Interstice, and how their desire to explore beyond traditional structural engineering led to the formation of the company. He discusses the potential of Mass Timber, highlighting its sustainability, aesthetic appeal, and cost-effectiveness. He also talks about the challenges of specialization and siloing in the AEC industry and explains how Interstice aims to create innovative solutions that span across various domains, bringing cohesiveness to the industry.

Eric emphasizes the importance of computational tools in today's design and engineering processes. He explains how he uses Rhino, Grasshopper, Python, and Revit in his workflow. Furthermore, he believes that integrating ShapeDiver into his process revolutionizes client engagement and project delivery. Guenther's insights provide a glimpse into the future of architectural engineering, where technology not only enhances design capabilities but also fosters collaborative and interactive client relationships.

1. Please introduce yourself and share a bit about your professional background, particularly concerning the AEC industry.

My name is Eric Guenther. I’m Co-Founder and Principal of Interstice and Digital Practice Manager at Forefront Structural Engineers (FSE). I’ve spent most of my career practicing as a structural engineer, but I’ve always focused on the AEC industry's broader aspects. I attribute much of that to my education in architecture, where I learned about design, integration, and systems thinking. Those concepts led me to pick up computational design, which initially served as a creative outlet but now underscores much of my work.

2. What was the key motivation or triggering event that inspired you to start your business in the AEC sector, specifically within Mass Timber?

My partner, Josh Dortzbach, and I founded Interstice to explore new ideas and expand into areas outside of pure structural engineering. We are particularly interested in spaces where we see opportunities for innovation. The triggering moment was when we found a client asking us to help them do just that.

Mass timber is in its relative infancy in the U.S. There is a real opportunity to help shape its future. The opportunity extends well beyond material-specific technologies and into the broader aspects of the industry. We saw this as an ideal opportunity to take on new challenges and help our clients navigate an evolving market.

3. Mass Timber has recently gained significant attention in the AEC industry. What do you think are the key factors driving its popularity?

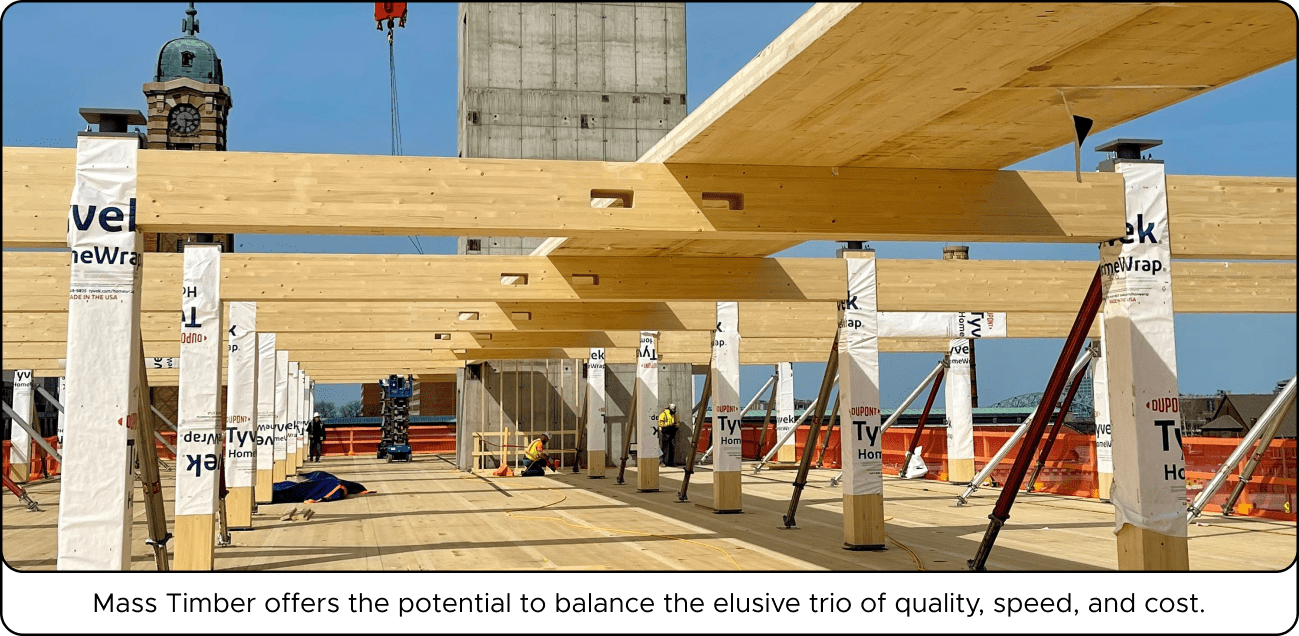

We haven’t seen many disruptions in structural materials over the past century. While timber itself is nothing new, mass timber offers the potential to balance the elusive trio of quality, speed, and cost. Most would agree that timber is beautiful and offers a promise of sustainability. It can be built quickly with small crews, and modern manufacturing capabilities have made it competitive from a cost perspective. Achieving all three is difficult, but the potential drives the popularity.

4. Looking at the AEC industry, what main challenges and opportunities do you aim to address with Interstice?

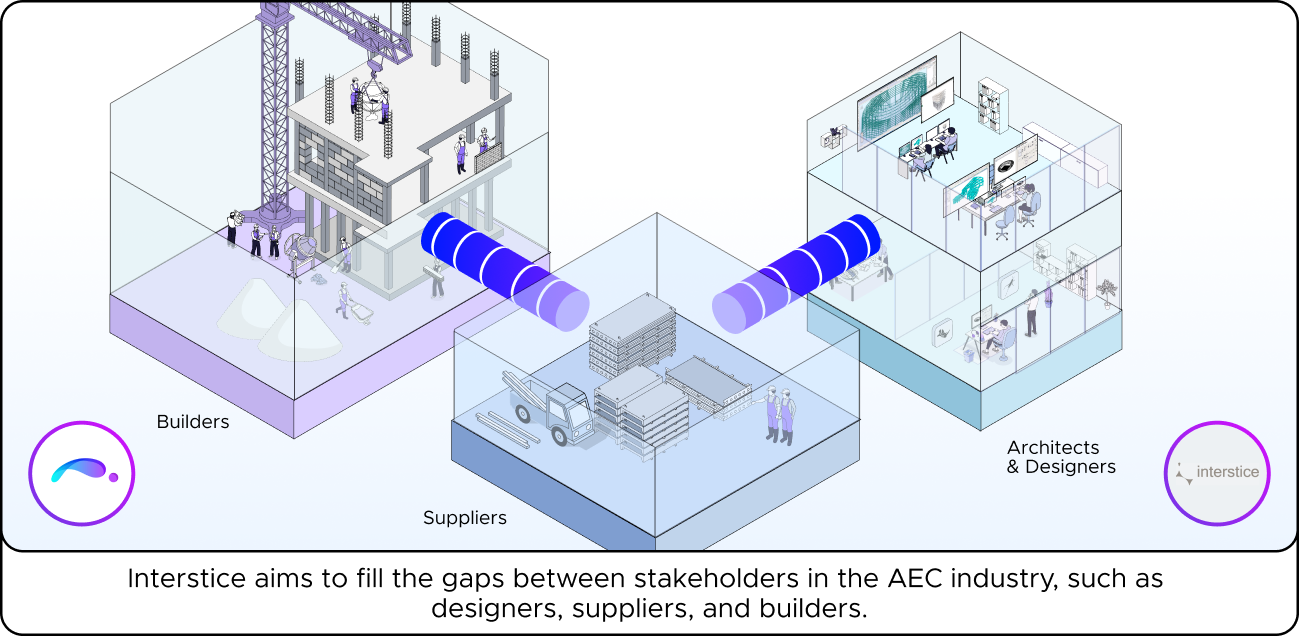

Throughout my experience in the AEC industry, I’ve seen a continuing trend toward hyper-specialization. Industry members are encouraged, if not required, to become experts in a smaller and smaller niche. This brings a lot of siloing between designers, suppliers, builders, etc. We started Interstice to fill the gaps between these silos. Rather than narrowing our focus, we’re choosing to broaden it. We work closely with our clients to identify their unique challenges and build custom solutions.

Specifically, within mass timber, we’ve looked at the entire project delivery method and identified opportunities for improvement. We’re focused on empowering early decision-making, streamlining the digital workflow between diverse teams, and simplifying the construction logistics process.

5. What is your current workflow/framework involving Rhino, Grasshopper, Python, Revit, etc.? At what point does ShapeDiver come into play?

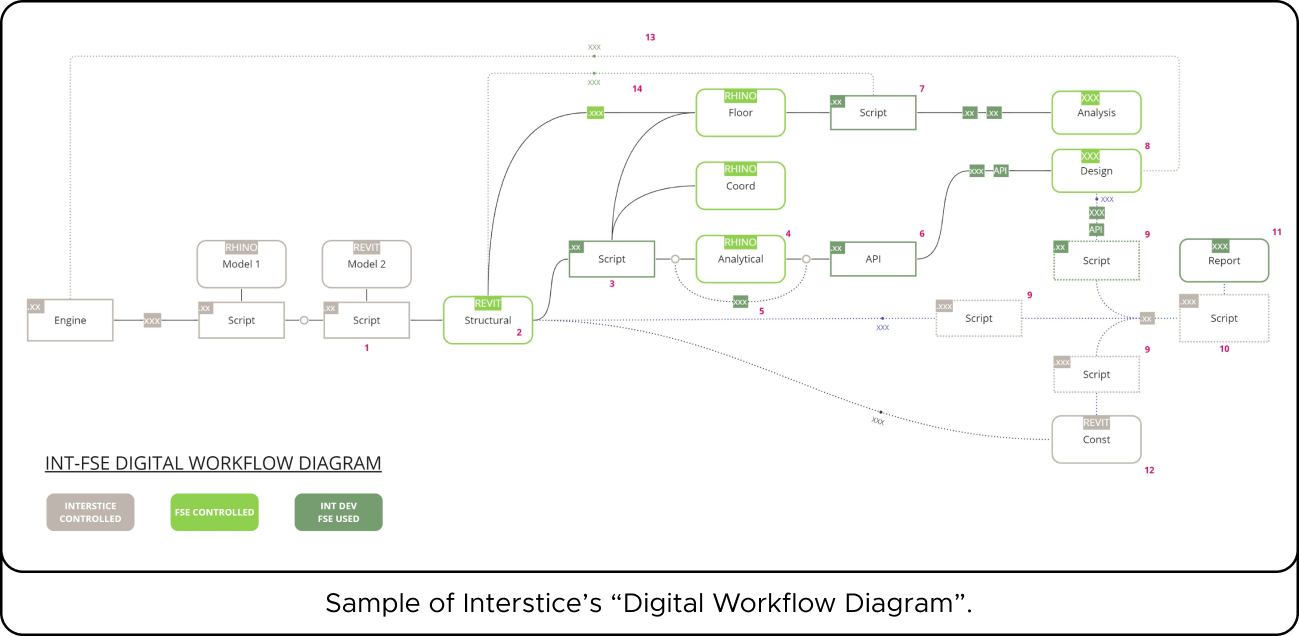

I’m drawn to many of these tools because they offer relative simplicity and a high degree of flexibility. Python provides a flexible but powerful environment for our raw engineering algorithms and data processing. Rhino and Grasshopper offer an intuitive way to work within a 3D environment that is not necessarily encumbered with building information. Therefore, most of my workflow centers around those tools, pushing and pulling information to other software as needed. By controlling the whole workflow, we’re able to minimize data loss, collaborate seamlessly, and explore meaningful information at the earliest stages of a project.

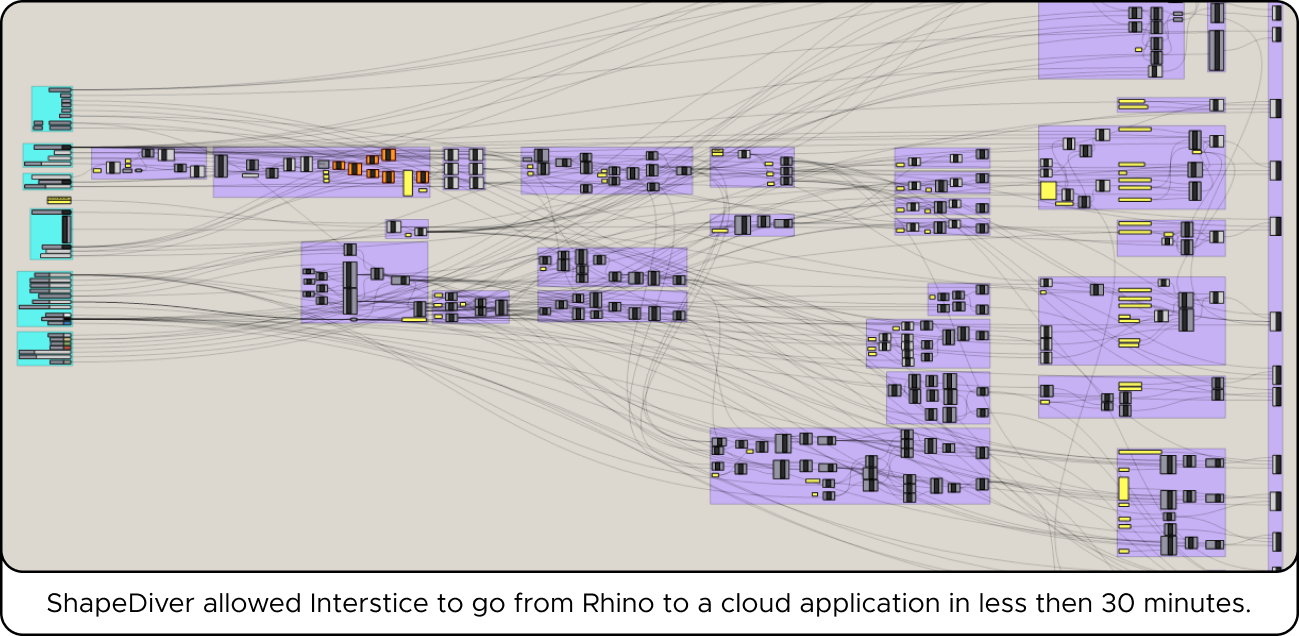

ShapeDiver enters the picture when we need to share interactive parts of this process with clients and collaborators. Often, the limitation of computational design tools is that they aren’t readily accessible to those not familiar with a programming environment. With ShapeDiver, we can quickly turn our solutions into interactive web apps that our clients and collaborators can explore without any programming knowledge.

6. Could you describe how you use ShapeDiver as part of your workflow?

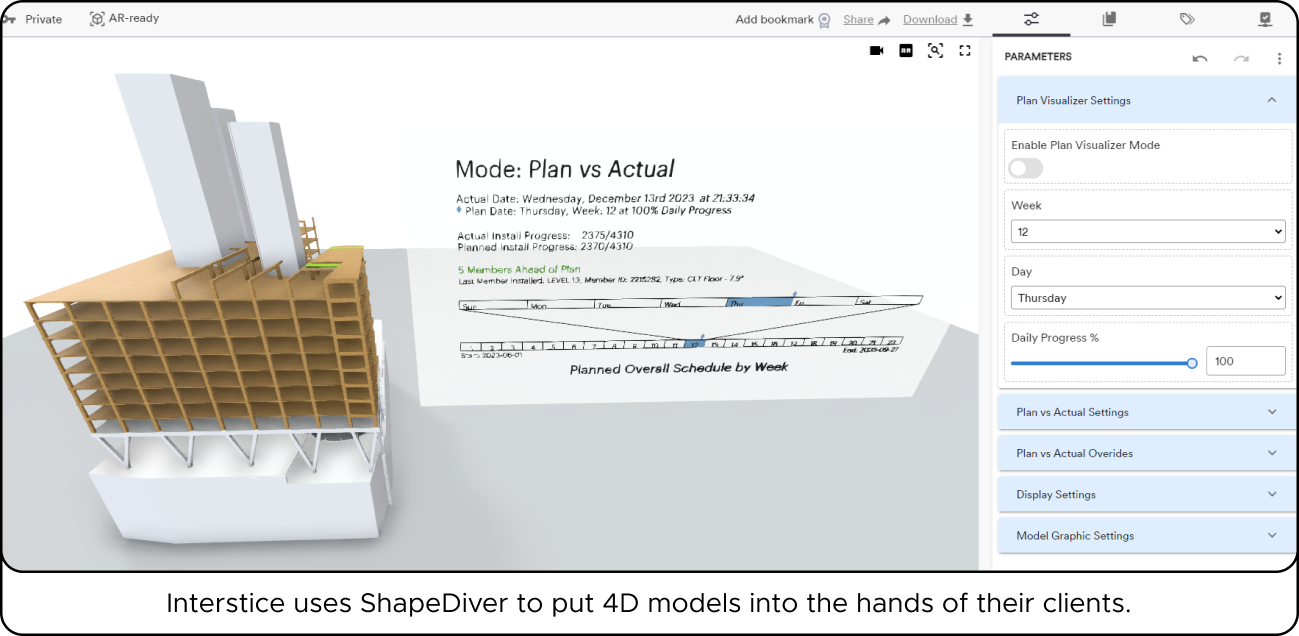

We primarily use ShapeDiver to put 4D models into the hands of the team. Adding the extra dimension of time to a model is powerful on its own. The ability to open that same model on a browser flips the script on accessibility. Because our workflow is primarily structured around Grasshopper, ShapeDiver integrates seamlessly. We can generate detailed 4D models of our earliest concepts, allowing team members easy access to critical information.

7. What are the specific challenges in mass timber projects that ShapeDiver helps to address?

One of the biggest challenges facing mass timber is capitalizing on schedule. On large-scale projects, it must be built fast to be successful. The problem is that capitalizing on the potential speed requires both a detailed plan and buy-in from multiple trades.

In traditional projects, the information required to develop the plan would come in the later stages of the project. With ShapeDiver, we’re able to put this information into anyone’s hands on day one. We can then collaborate with stakeholders and refine the plan collectively. This benefits not just the mass timber trades but every trade that needs to capitalize on its speed.

8. How does ShapeDiver enhance your interaction with clients and partners?

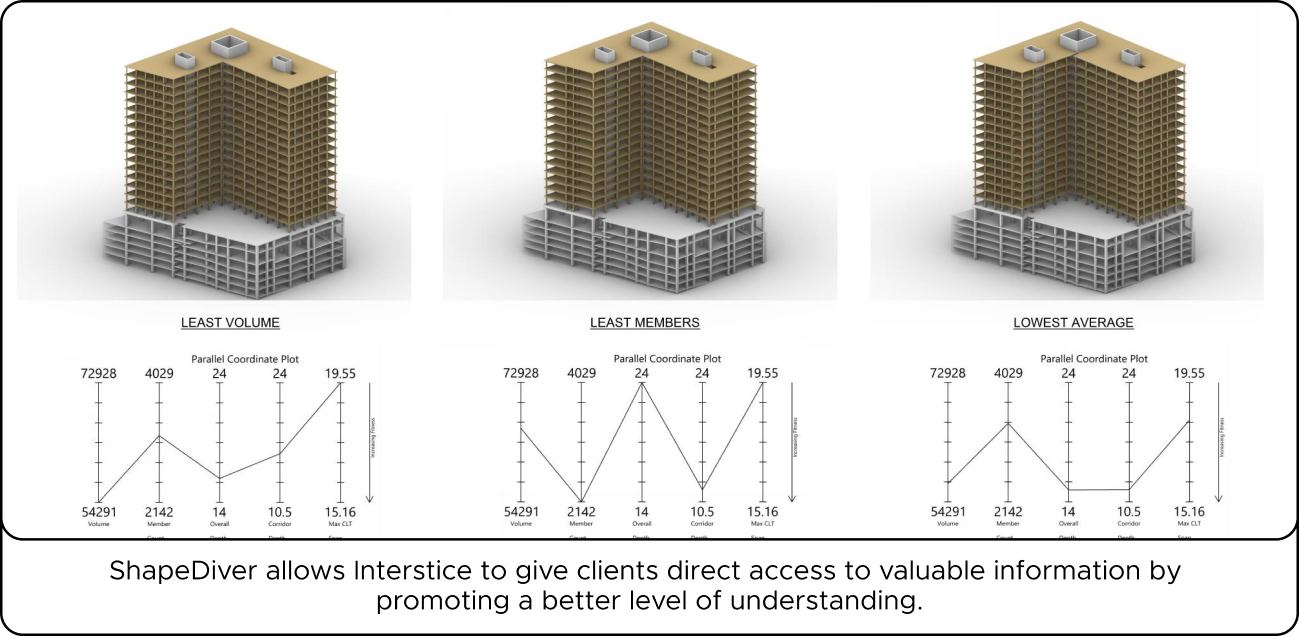

One of the most important parts of our business, and one of the biggest challenges facing our industry, is understanding our collaborator’s and client’s needs. ShapeDiver allows us to give clients direct access to valuable information, but more importantly, it promotes a better level of understanding. It’s pretty powerful to build out a tool and, within minutes, have your clients or partners explore it on a web app. It’s even more powerful when they can give you live feedback on how that tool applies to their problem. This level of engagement multiplies the tool's value in a way that is hard to achieve otherwise.

9. Are there any plans or improvements you're considering for ShapeDiver's integration into your workflow?

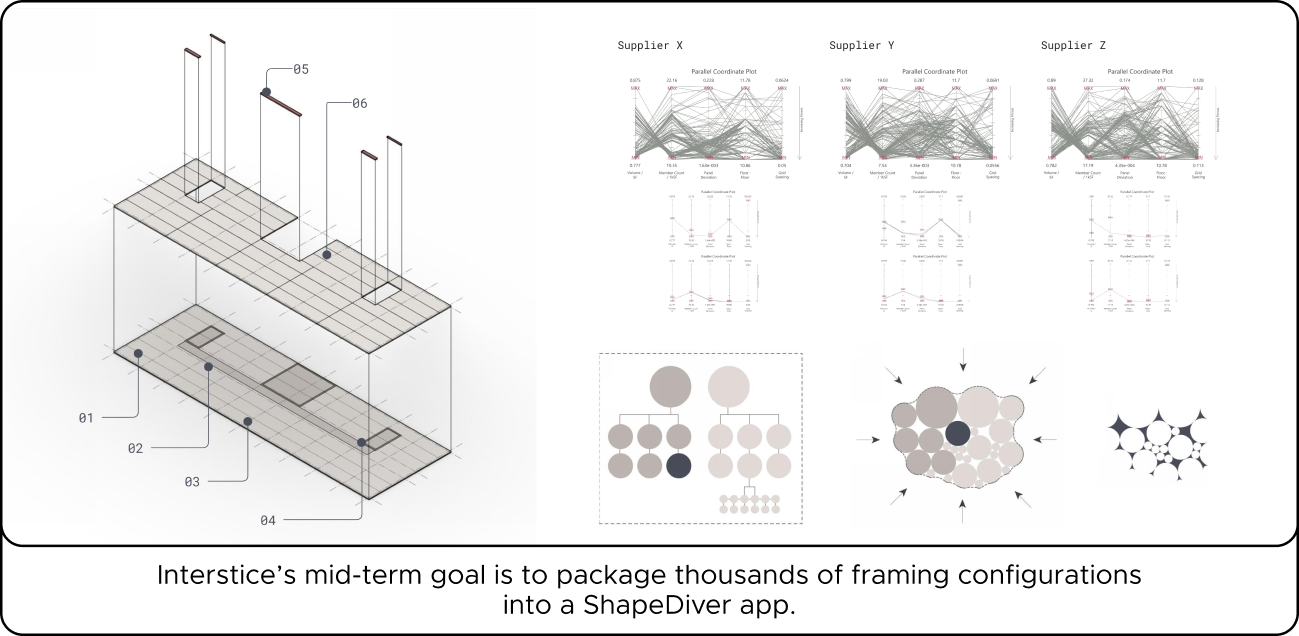

In the early optimization phase of our workflow, we generate thousands of framing configurations. Representing a select few of these configurations has always been one of the more static parts of an otherwise fluid process. We’re currently exploring ways to package this entire model in ShapeDiver. This would allow us to recommend a few configurations while still giving access to all of them. We hope this will dramatically increase engagement and promote more exploration at this critical stage.

10. Are there any specific features of ShapeDiver that you find particularly beneficial or unique compared to other tools?

I look for tools that are simple to use and get you up and running quickly. I probably spent less than 30 minutes getting my first functional script deployed. I didn’t have to learn web development or how to host my own server; I barely had to modify my Grasshopper script. ShapeDiver is no-nonsense for users like me but offers the potential to build something more powerful when needed.

11. What advice would you give to other professionals in your industry considering integrating ShapeDiver into their workflow?

Keep it simple. Building a highly effective and powerful script that only you understand is relatively easy. It’s much harder to put that in someone else's hands and have them understand it intuitively. We’re dozens of iterations into one of our tools and still simplifying it. The simplest version that conveys the idea is all you need.

- Well, this has been great, Eric. Thank you very much for your time today!

Thank you as well for this opportunity.

That's it for this new edition of Getting to know... Don't forget to visit Insterstice's website and LinkedIn page.

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/7f0e22f46b/interstice-cover.webp)