Introduction

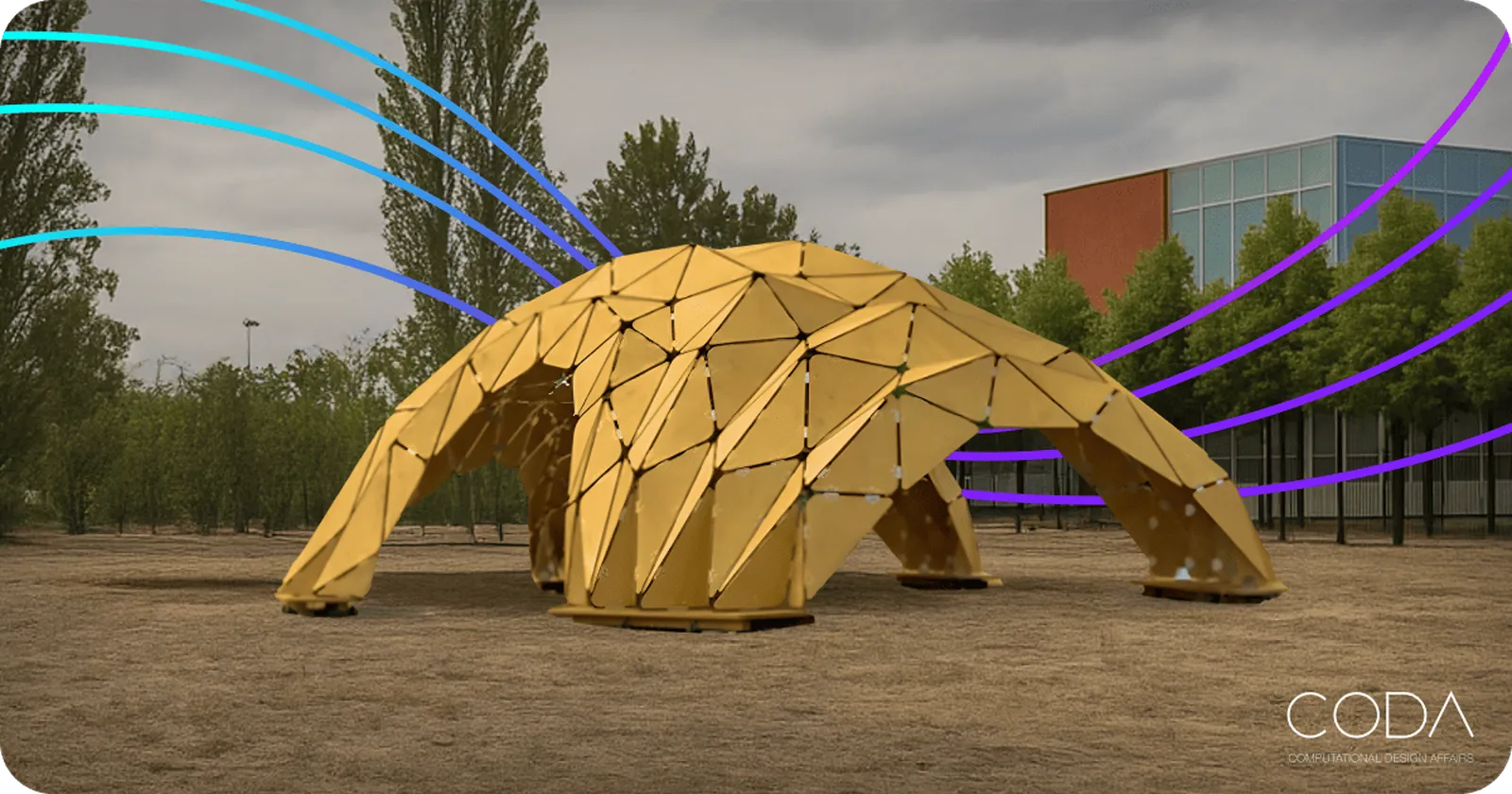

Meet the team behind CODA, a forward-thinking collective of architects, engineers, and computer scientists dedicated to creating adaptable architectural systems. With roots in early visual programming tools and a passion for bridging geometry, construction, and structure, the team developed PENTAURA, a timber shell configurator powered by ShapeDiver’s App Builder, designed to bring sustainable design to a broader audience.

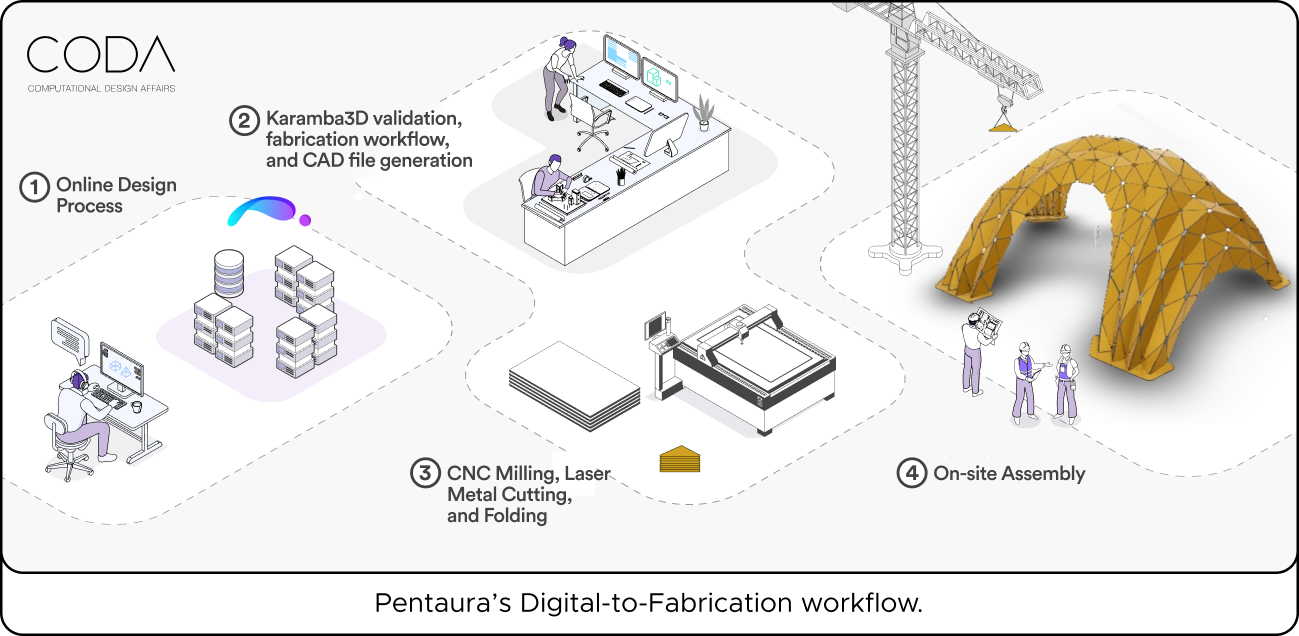

In this interview, you’ll learn how PENTAURA leverages Grasshopper to power a generative system that balances user input with engineering constraints, Kangaroo2 for form-finding, and Karamba3D for structural validation. Once a design is finalized, automated workflows generate CNC- and laser-ready fabrication files, enabling fast and precise manufacturing through a distributed European network of robotic timber workshops.

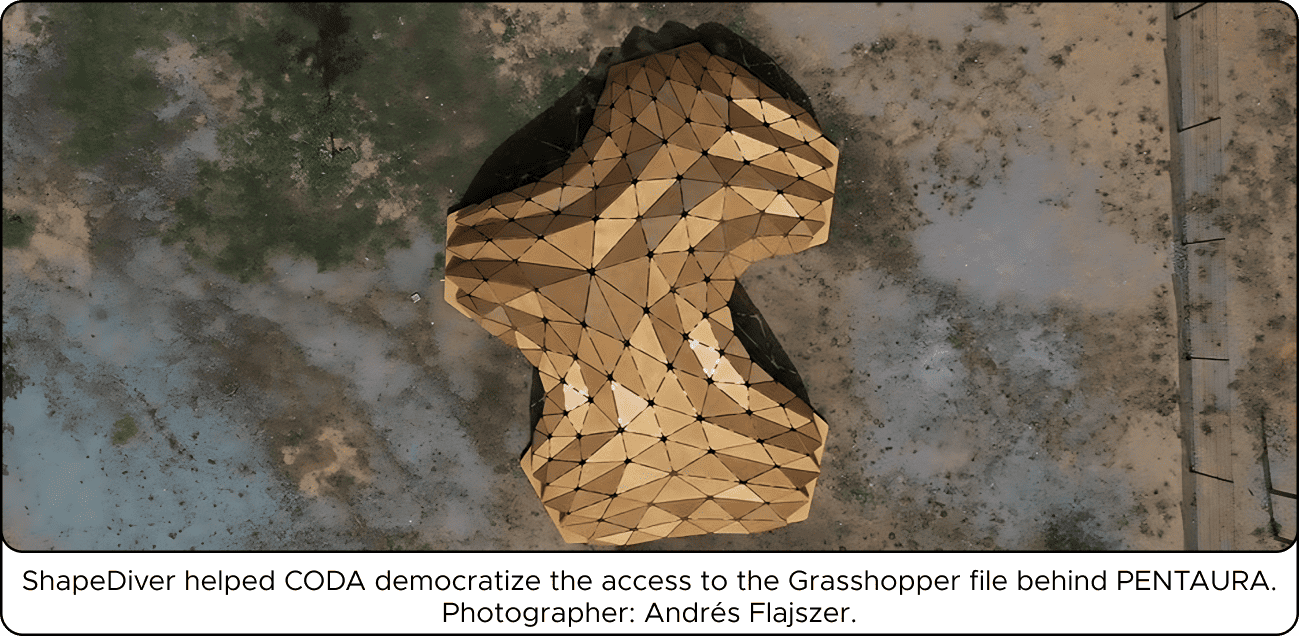

By integrating with ShapeDiver, CODA enabled access to complex parametric design tools through a user-friendly online experience made with App Builder. This expands the reach of computational design to municipalities and small studios and aligns with CODA's broader mission of democratizing technology, fostering sustainability, and empowering local fabrication. Let’s dive in!

NOTES: This project has indirectly received funding from the European Innovation Council and EISMEA, European Commission COSME-SMP-2021- CLUSTER. FRIEND CCI PROJECT.

The system was first developed in an academic setting at MPDA with a group of students for a local school. It was later used as the first of many building systems to be implemented in ShapeDiver.

1. Please tell us about CODA and its team members. What’s everyone’s background? When did you get started?

Before finishing our architecture studies, a group of friends was united by a special interest in the relationship between geometry, construction, and structures. In 2007, we found Generative Components, a visual programming CAD software similar to Grasshopper, and started a process of self-learning through small tutorials on the nascent internet and attending conferences while testing all this gained insight in design competitions.

In 2011, we founded CODA on the occasion of a couple of small research grants. Although it was hard to create a niche, we have been growing at a slow but steady pace, with the vision of designing not just architectural solutions for a site or a specific client, but systems that can be tailored and implemented while creating a greater family of solutions.

2. For someone new to Grasshopper, how would you describe its role in creating PENTAURA?

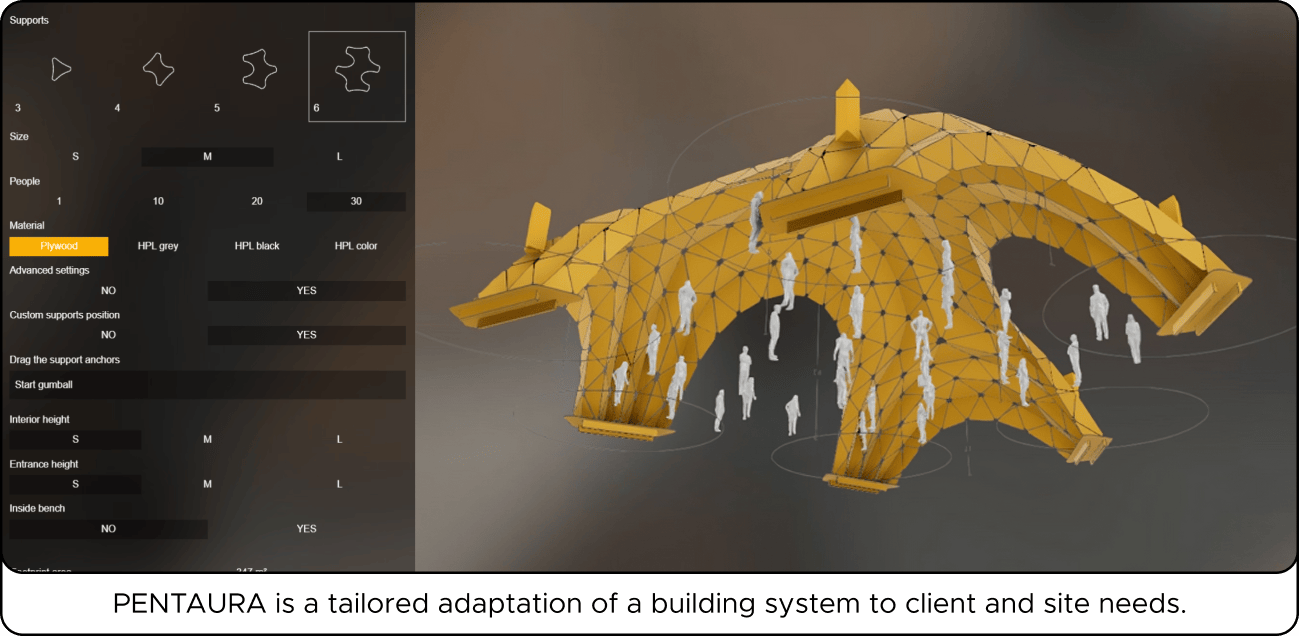

PENTAURA is not a closed product but rather a tailored adaptation of a building system to client and site needs. Designing the final solution while keeping the shape within a certain range of different hard constraints is at the core of this generative system. In this regard, Grasshopper is the perfect language to rationalize building systems, making them easily adaptable and efficient.

3. What were some of the most complex design parameters you had to manage, and how did parametric modeling help resolve them?

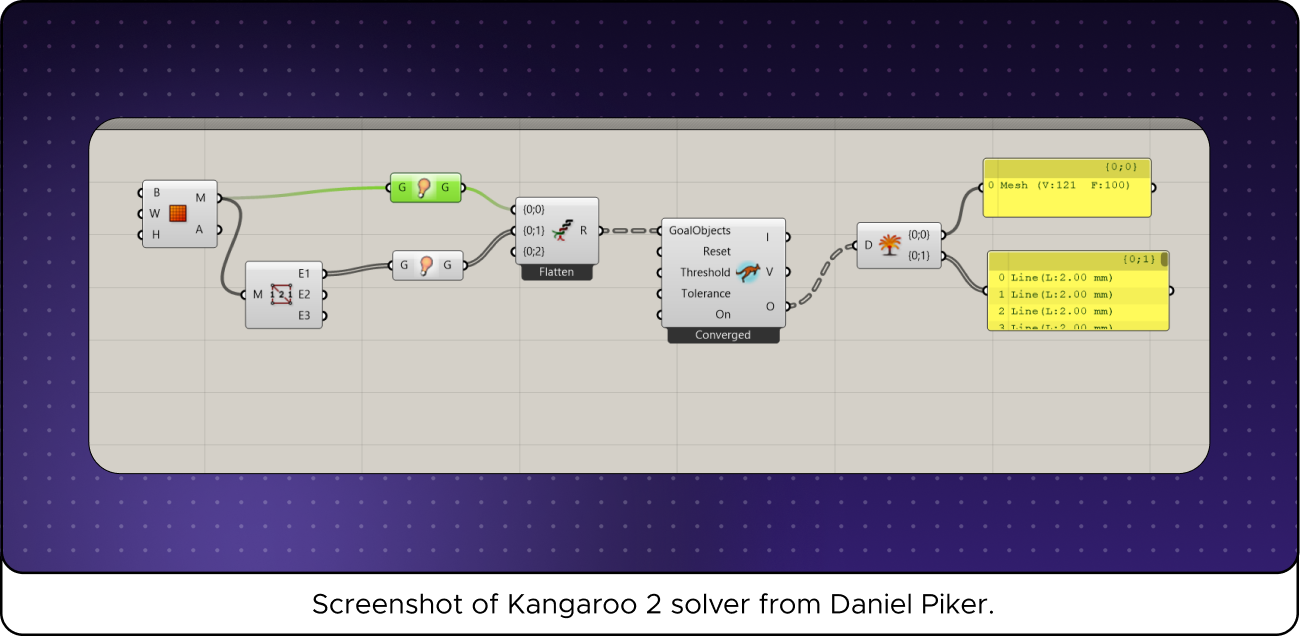

One of the key aspects is that the form-finding is purely driven by the fantastic kangaroo2 solver from Daniel Piker. Without it, we could approximate efficient forms, but this dynamic relaxation implementation is flexible and fast, making it perfect for shells. Additionally, numerous optimizations have been implemented to enhance the configurator's responsiveness.

4. How does structural feedback, via Karamba3D, influence the real-time configurator experience for end users?

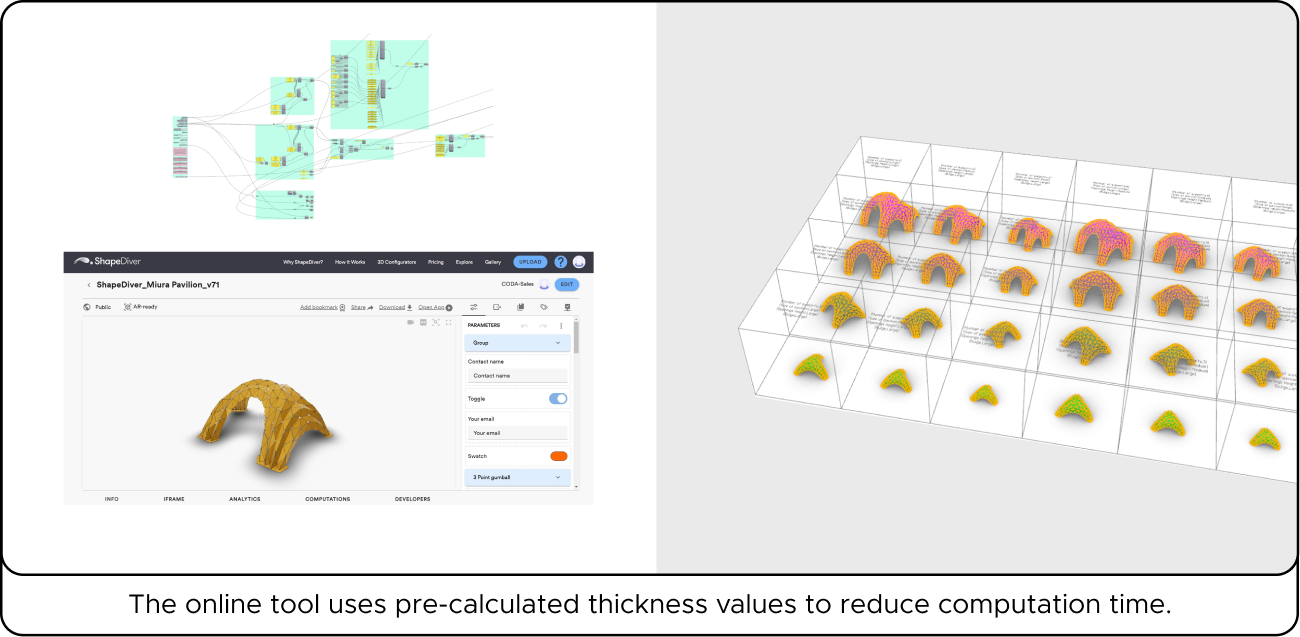

In the ShapeDiver configurator, the material thickness is retrieved directly from a pre-calculated table. Karamba3D is not used in this online version to save computation time. Once a project is agreed upon, we conduct a thorough Karamba3D analysis for verification and reporting.

5. In what ways did automation contribute to reducing the time from concept to fabrication-ready output?

In our design projects, automation facilitates several feedback loops with manufacturers and builders, so we don’t need to redraw; instead, we adapt and refine based on their needs. In these projects, we don’t reduce time.

In contrast, in projects where we provide automation as a service, or where we replicate the building system, like in PENTAURA, and the automatic redraw is for the same design, the impact can be drastically reduced. Our best case is a 3-minute workflow versus a 3-week manual drawing of a complex membrane system for pressurized tanks.

6. What role does local fabrication across Europe play in making timber construction more sustainable and resilient?

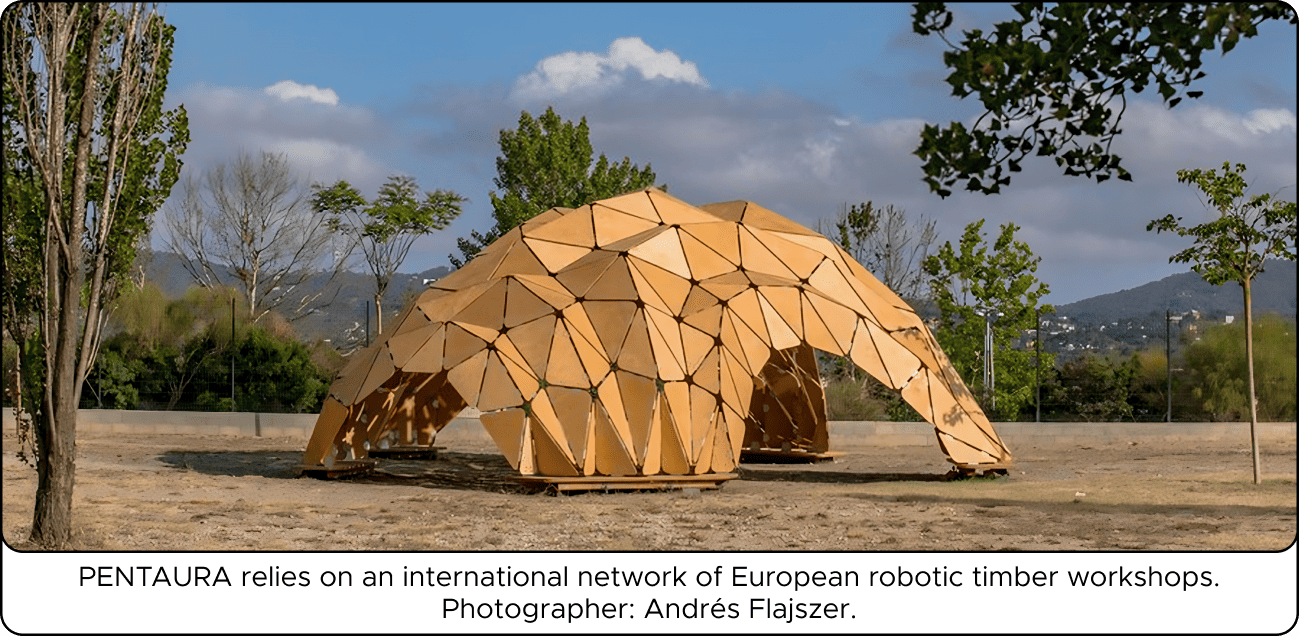

In the PENTAURA business model, we will rely on an international network of small robotic timber workshops across Europe, where we only need to send fabrication files.

7. How do you envision timber and modular systems shaping future urban landscapes, especially for temporary and adaptable spaces?

PENTAURA is a dry-tech solution that is fully reversible. With the early prototypes, we have calibrated assembly time to make the system appealing to clients eager to create a space to share and play.

We are based in Spain, and from the beginning, we have aimed to create climate shelters that can host different activities in public spaces. Protecting public spaces in Europe against the climate and isolation crises is a fundamental concern. We need to extend the life and usability of these spaces by introducing more shade in central public areas, as this is at the core of the fundamental principles of communication, sharing, reunion, and activities that have shaped European culture.

8. Can you walk us through the digital-to-fabrication workflow that takes place once a user finalizes a design on the configurator?

Once the design is set, we run a Karamba3D validation process and a fabrication workflow. This latter process runs through labeling and basic geometry operations to directly output two CAD files with manufacturing layers for CNC timber milling, laser metal cutting, and folding. The nesting is created in a manner that is finished and packaged for assembly to minimize the spread of pieces on site.

9. How important was ShapeDiver's web-based platform in making the configurator accessible to a broader audience, including public authorities and urban planners?

ShapeDiver makes it very easy for Grasshopper users with no experience or time to train in web development. The workflow is straightforward because, from the very beginning, you feel confident using the tools. Additionally, the forum and support are quite user-friendly.

10. One of PENTAURA’s goals is to democratize access to advanced design technologies. How do you see this impacting education, municipalities, and smaller architectural studios?

ShapeDiver and similar tools will enable adaptable parametric projects in offices to become accessible to a much broader audience. This can allow useful, rational, sustainable computational design to transcend offices and reach more traditional clients.

11. What lessons did you learn through your collaboration with CODA, ShapeDiver, and Karamba3D that might apply to other interdisciplinary projects?

It has been very fruitful to discuss a wide range of technical questions early on so that the development can be better framed. It can happen that you do not entirely know each part, so the earlier you start having technical meetings, the better.

12. What are your plans for the next evolution of PENTAURA? Are there new features or use cases you are excited about (e.g. structural feedback, cost estimation, AI-assisted design)?

We are definitely interested in the assistance AI can provide to a user to better define the parameters according to a basic description of their specific demands. Additionally, we aim to find good trade-offs and effective combinations.

13. Finally, what advice would you give to architects or designers looking to embrace computational design tools in their own practice?

Yes! Enroll in the master MPDA that we direct!

- Excellent! Thank you very much for all of your time.

Thank you as well for this chance to share our work.

That's it for this new edition of Getting to know... Don't forget to visit CODA's website and follow them on their social media channels!

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.